Smelting method of low carbon steel for mechanical structural pipe

A technology of mechanical structure and smelting method, applied in the direction of improving process efficiency, etc., can solve the problems of small output, high application professionalism, and limited amount of low-carbon steel used in mechanical structure pipes, etc., to achieve increased strength, high product strength, The effect of continuous casting process stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in combination with specific embodiments.

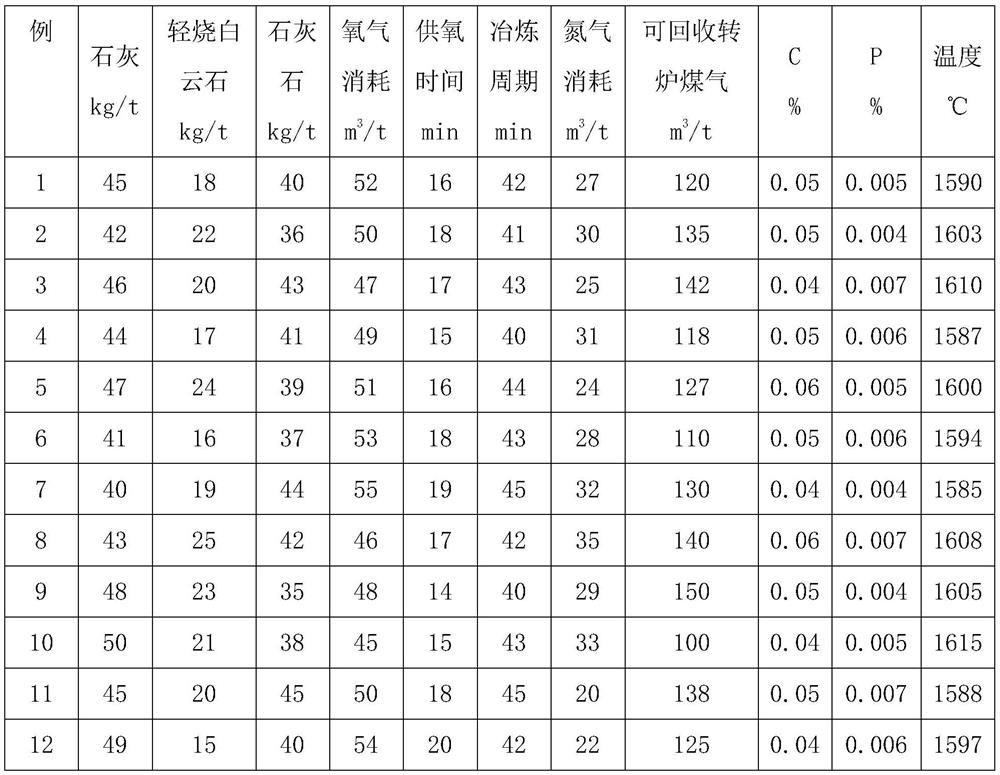

[0019] Examples 1-12: The smelting process of low-carbon steel for mechanical structural pipes adopts the "BOF(100t)-LF(120t)-VD(120t)-CC (arc radius R14m)" process flow, and the process parameters of each process are as follows mentioned.

[0020] (1) BOF converter smelting process: molten iron requires P≤0.110wt%, S≤0.020wt%, Si 0.20-0.60wt%, temperature 1300-1450°C. After the smelting of the previous furnace is completed, 2-5 tons of steel slag is left in the converter furnace, and nitrogen is blown from the bottom to splash slag to protect the furnace. 3 / h. The ratio of molten iron scrap in converter is: 80-85% of molten iron and 15-20% of scrap. Before smelting, the converter slag near the converter cap must be cleaned. If splashing occurs during the blowing process, the remaining converter slag in the furnace cap must be cleaned a second time to ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com