Electromagnetic stirring control method and system for continuous casting

A technology of electromagnetic stirring and control method, applied in the field of continuous casting, can solve the problems of affecting the performance of rolling materials, large changes in drawing speed, and inability to implement, and achieve the effects of improving internal quality, reducing center porosity, and reducing center segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

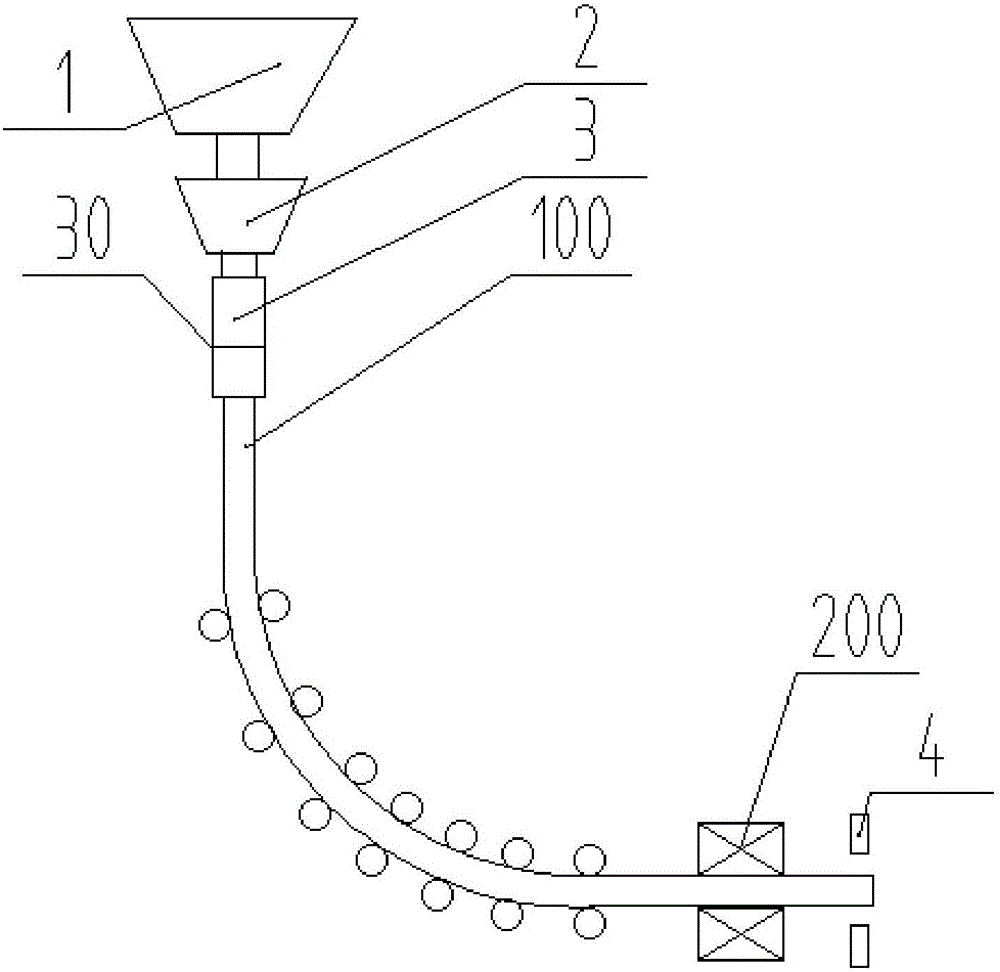

Image

Examples

Embodiment Construction

[0023] In the following description, for illustrative purposes, many specific details are set forth in order to provide a comprehensive understanding of one or more embodiments. However, it is obvious that these embodiments can also be implemented without these specific details. In other examples, for the convenience of describing one or more embodiments, well-known structures and devices are shown in the form of block diagrams.

[0024] Hereinafter, various embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

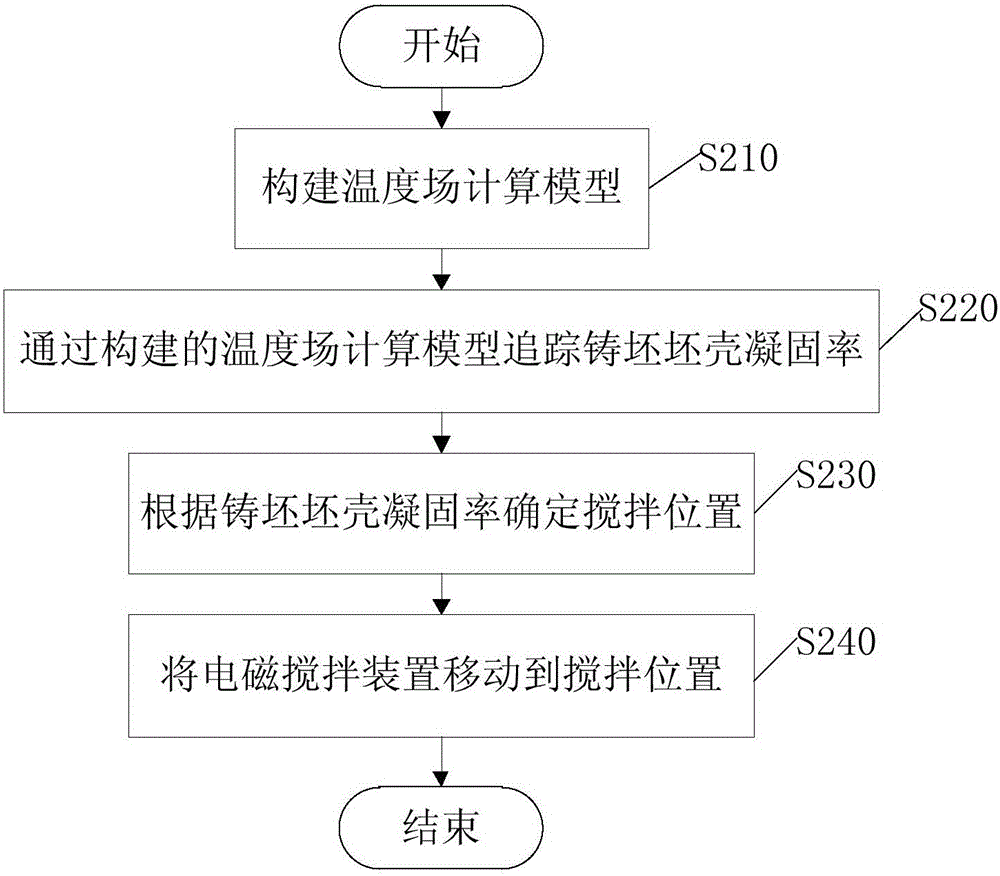

[0025] figure 2 It is the flow chart of the electromagnetic stirring control method for continuous casting of the present invention, such as figure 2 As shown, the electromagnetic stirring control method for continuous casting includes:

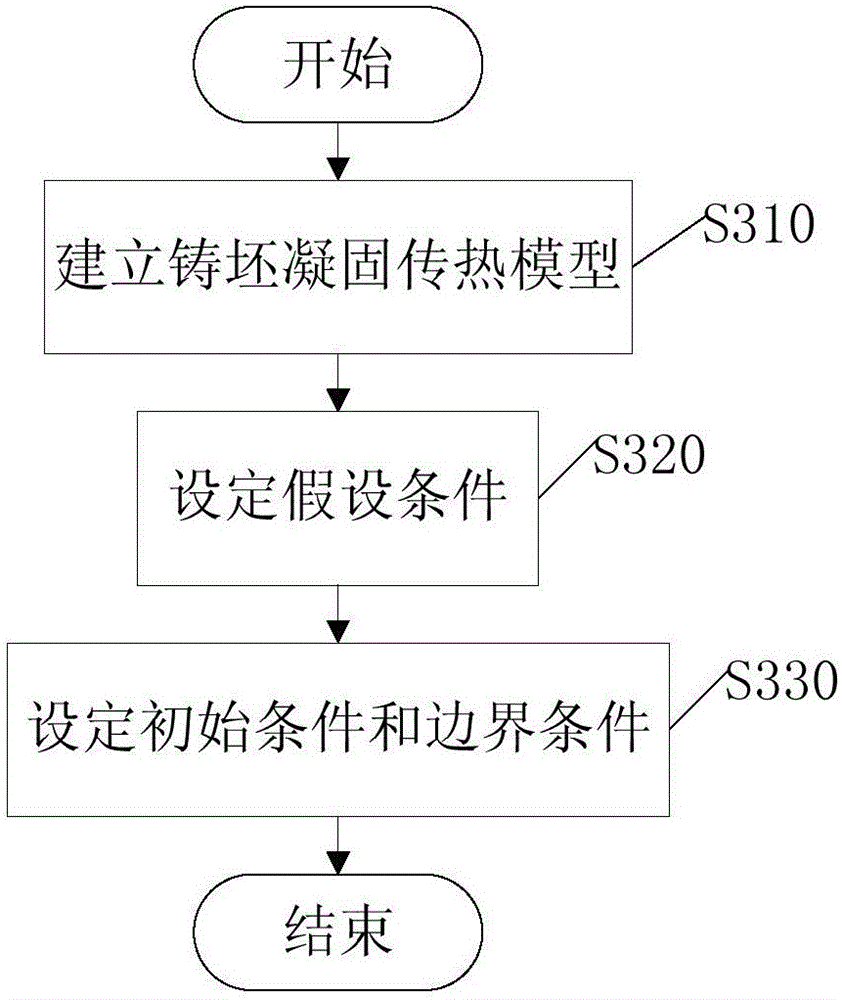

[0026] In step S210, a temperature field calculation model is constructed, and the specific process will be image 3 Detailed explanation in the description;

[0027] After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com