High-quality alloy steel bar and production process thereof

A production process and high-quality technology, applied in the field of metallurgy, can solve problems such as large differences in composition and easy occurrence of unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] This embodiment is a 16CrMnBH high-quality composite steel bar, which includes the following components by weight percentage: C: 0.157%, Cr: 0.98%, Mn: 1.17%, Ti: 0.012%, Si: 0.26%, P : 0.01%, S: 0.017%, Al: 0.030%, N: 0.0120%, Mo: 0.03%, V: 0.12%, Ni: 0.03%, Cu: 0.090%, B: 0.0018%, O: 0.0014%, Fe And unavoidable impurities: balance.

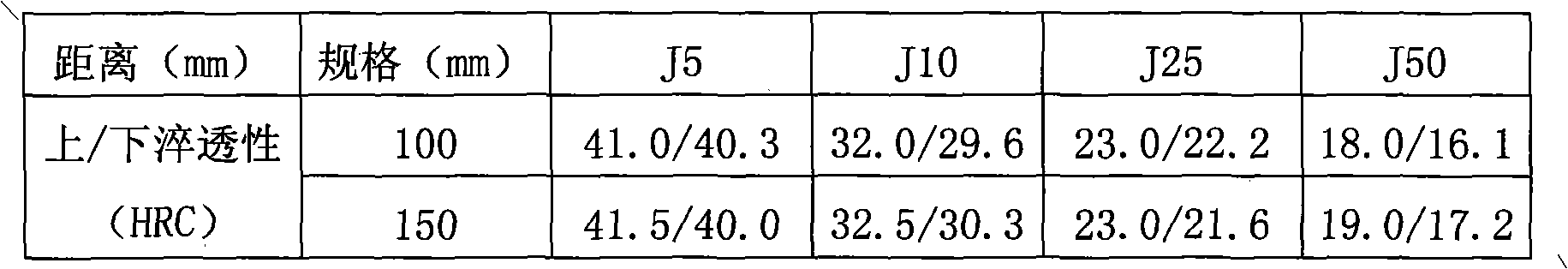

[0015] In this example, two batches of bars with two specifications of φ100mm and φ150mm were rolled. The specific procedures are as follows:

[0016] 100t ultra-high power electric arc furnace smelting: the high temperature generated by electrode discharge will melt the scrap steel and remove impurities such as P and S.

[0017] 100tLF refining: deoxidize, adjust the content of C, Mn, Si, Cr and other elements according to the requirements, and remove the inclusions in the molten steel through static stirring.

[0018] 80tVD vacuum treatment: remove O, N, H and other gas inclusions in a vacuum degree below 1Mba.

[0019] Three-machine three-flow...

Embodiment 2

[0038] This embodiment is a 15B36Cr high-quality composite steel bar, which includes the following components by weight percentage: C: 0.331%, Cr: 0.31%, Mn: 1.26%, Ti: 0.013%, Si: 0.28%, P : 0.009%, S: 0.004%, Al: 0.030%, N: 0.0120%, Mo: 0.02%, V: 0.3%, Ni: 0.02%, Cu: 0.050%, B: 0.001%, O: 0.001%, Fe And unavoidable impurities: balance.

[0039] In this example, a batch of φ120mm bars was rolled, and the specific procedures are as follows:

[0040] 100t ultra-high power electric arc furnace smelting: the high temperature generated by electrode discharge will melt the scrap steel and remove impurities such as P and S.

[0041] 100tLF refining: deoxidize, adjust the content of C, Mn, Si, Cr and other elements according to the requirements, and remove the inclusions in the molten steel through static stirring.

[0042] 80tVD vacuum treatment: remove O, N, H and other gas inclusions in a vacuum degree below 1Mba.

[0043] Three-machine three-flow alloy steel continuous casting machine co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com