Low-manganese thick Q355B steel plate and manufacturing method thereof

A technology of Q355B and manufacturing method, which is applied in the field of iron and steel metallurgy, can solve the problems of high production cost and high position, and achieve the effect of suppressing center segregation and improving low-fold quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

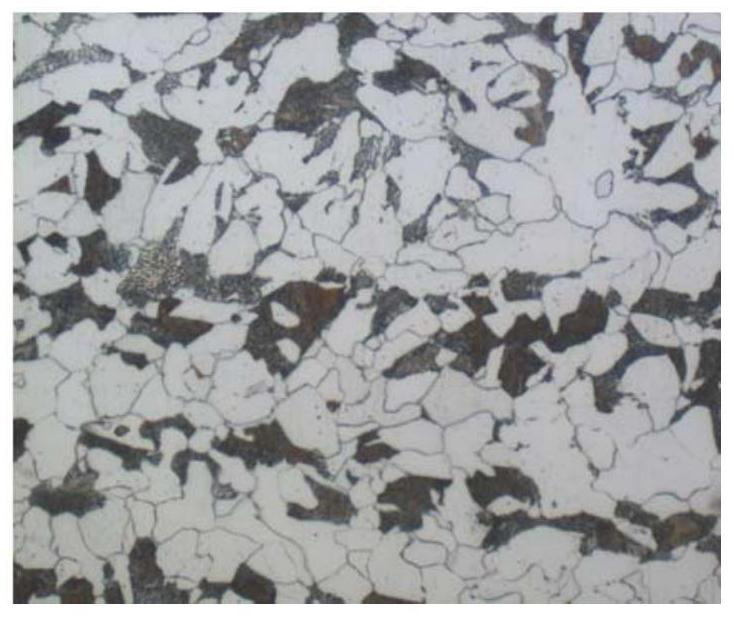

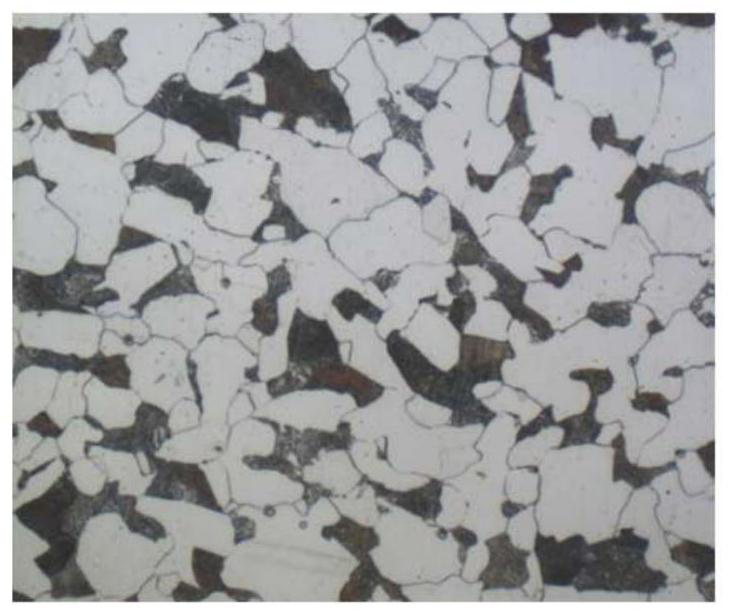

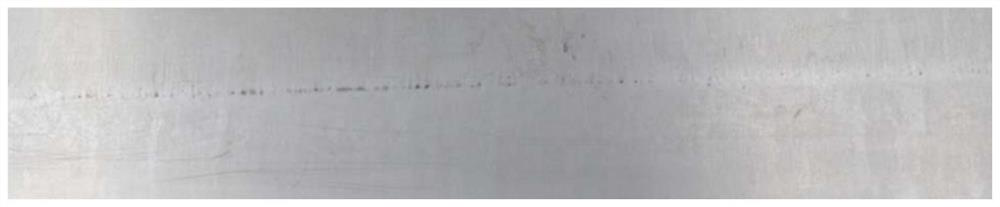

Image

Examples

Embodiment Construction

[0025] The following examples may enable those skilled in the art to more fully understand the present invention, but do not limit the present invention in any way.

[0026] A process route of Q355B steel plate with low manganese thickness specification is: molten iron KR pre-desulfurization, converter smelting, LF refining, slab continuous casting, slab reheating, rough rolling-finishing rolling-steel plate rapid cooling-steel plate hot straightening-upper cooling bed Cooling-finishing-storage, the control parameters of the smelting heat and the mother plate rolling process in this embodiment are shown in Table 1, the melting components of the smelting heat are shown in Table 2, and the mechanical properties of the hot-rolled mother plate are shown in Table 3. Among them, the tensile impact performance test standard in Table 3. According to GB / T 228 and 229.

[0027] Table 1: Example smelting heats and master plate rolling process control parameters

[0028]

[0029] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com