Small-compression-ratio thick controlled rolling Q345GJ steel plate for building structure and production method thereof

A Q345GJE, building structure technology, applied in the field of high-quality steel product manufacturing, can solve the problems of long manufacturing cycle, poor weldability and high alloy content, and achieve the effect of improving welding performance, shortening manufacturing cycle and simplifying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

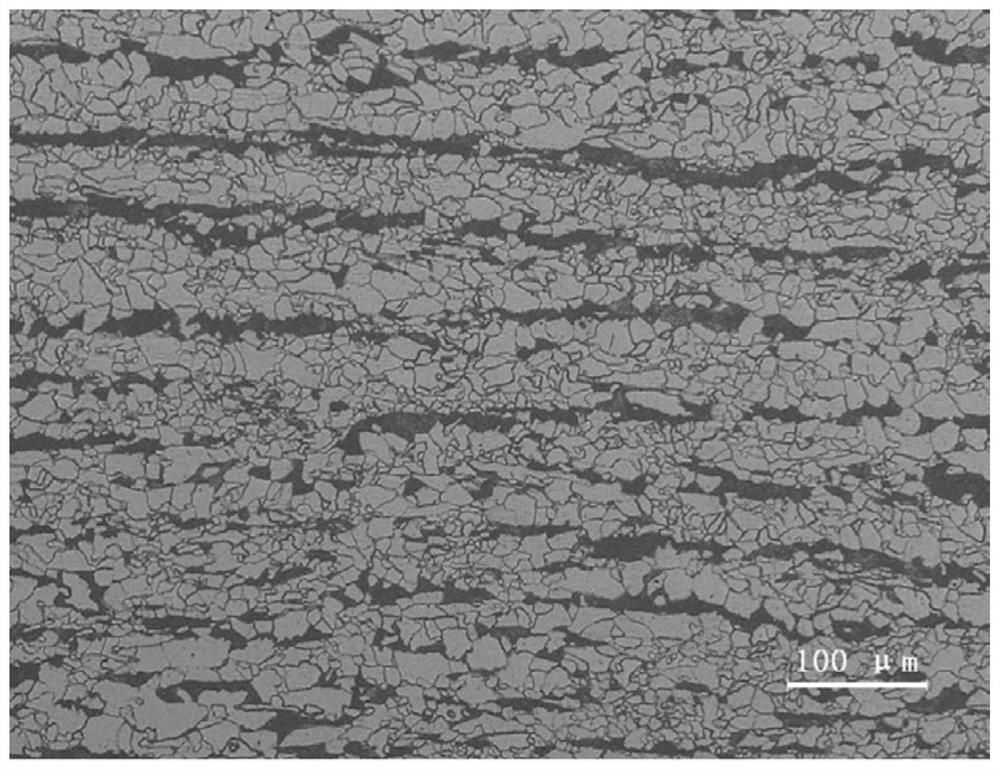

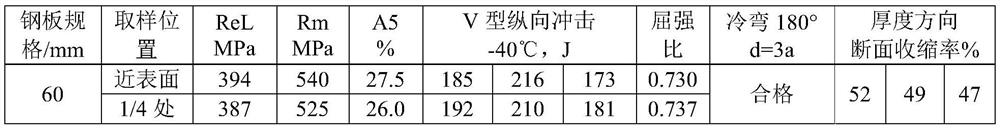

[0044] According to the scope of the chemical composition provided by the present invention, according to the above process flow and the specified process conditions, molten steel is smelted on a 120t converter, and the molten steel is cast into a 250mm thick slab, and after slow cooling and reheating, it is rolled on a 3500mm wide and thick plate rolling mill 60mm steel plate.

[0045] The chemical composition of the steel plate is: C 0.15%, Si 0.28%, Mn 1.34%, P 0.015%, S 0.004%, Als 0.032%, Nb 0.021%, Ti 0.016%, CEV 0.37%.

[0046] The heating, rolling, and normalizing processes are as follows: the furnace temperature is 1150°C, the rough rolling intermediate billet thickness is 110mm, the finishing rolling start temperature is 818°C, the final rolling temperature is 812°C; the water inlet temperature is 772°C, 20 sets of cooling water are turned on, The channel speed is 45m / min, the outlet water temperature is 589°C, and the red return temperature is 625°C.

[0047] The p...

Embodiment 2

[0053] The technological process of the present invention is: blast furnace molten iron→pre-desulfurization of molten iron→converter smelting→deoxidation alloying→LF refining→VD refining→slab continuous casting→slab off-line stacking and slow cooling→slab cleaning→slab reheating→ 3500 rolling mill rolling → laminar cooling → steel plate stacking slow cooling → finished product sampling inspection → storage.

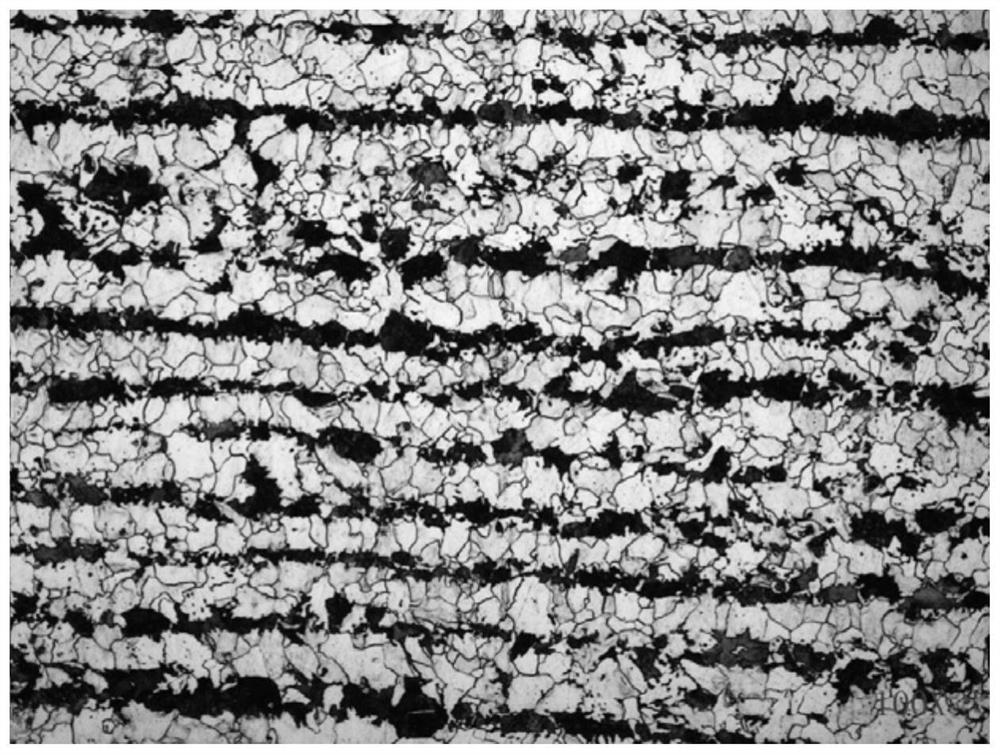

[0054] According to the scope of the chemical composition provided by the present invention, according to the above process flow and the specified process conditions, the molten steel is smelted on a 120t converter, the molten steel is cast into a 250mm thick slab, and after reheating, an 80mm steel plate is rolled on a 3500mm wide and thick plate rolling mill .

[0055] The chemical composition of the steel plate is: C 0.15%, Si 0.34%, Mn 1.35%, P 0.014%, S 0.003%, Als 0.038%, Nb 0.024%, Ti 0.018%, CEV 0.375%.

[0056] The heating, rolling, and normalizing processes are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| carbon equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com