A special submerged arc horizontal welding flux for pressure storage tanks

A pressurized storage tank and flux technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high price, improve the intergranular structure, ensure the yield ratio, refine the grain grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) The weight parts of various raw materials in the flux powder are as follows: (parts)

[0030] Calcium Oxide Magnesium Oxide Aluminum oxide Calcium fluoride Barium fluoride Rutile 813237912 Manganese Ore Powder Manganese Metal Ferrosilicon alloy Ferromolybdenum alloy Ferro Titanium Ferro Boron 78.56420.5

[0031] (2) The binder is high-modulus potassium sodium water glass with a modulus of 3.0-3.1 and a potassium-sodium ratio of 2:1.

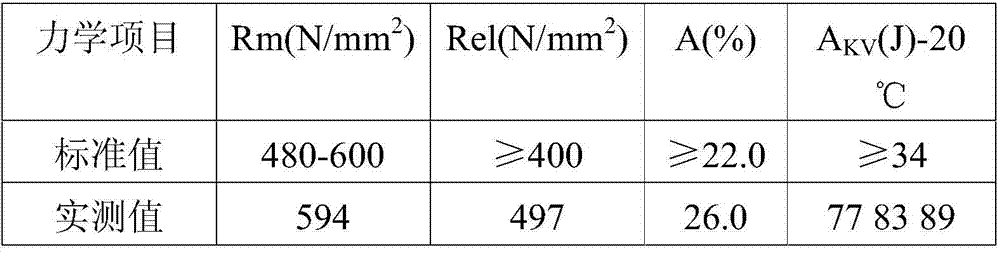

[0032] (3) The submerged arc flux is made according to the above composition for testing. According to the national standard GB / T 12470-2003, with submerged arc welding wire H10Mn2 for pressure storage tanks, chemical composition analysis of deposited metal and mechanical performance test of deposited metal . Welding specification: the welding power supply is DC reverse connection, the welding heat input is 18-19KJ / cm, and the interpass temperature is 145-150℃.

[0033] ①Flux type: active flux.

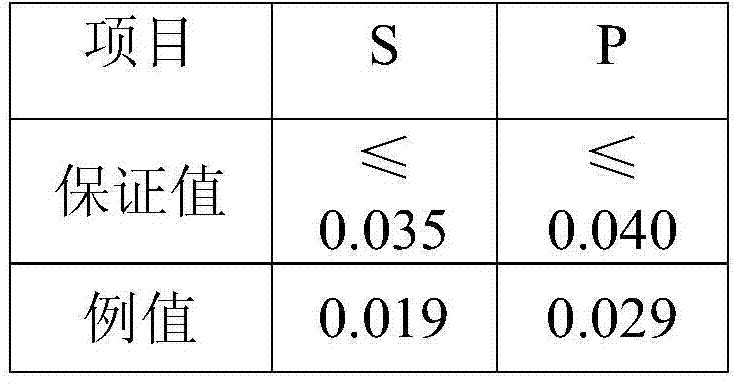

[0034] ②S / P content of flux:

[0035] ...

Embodiment 2

[0042] (1) The weight parts of various raw materials in the flux powder are as follows: (parts)

[0043] Calcium Oxide Magnesium Oxide Aluminum oxide Calcium fluoride Barium fluoride Rutile 1414206912 Manganese Ore Powder Manganese Metal Ferrosilicon alloy Ferromolybdenum alloy Ferro Titanium Ferro Boron 77541.60.4

[0044] (2) The binder is high-modulus potassium sodium water glass with a modulus of 3.0-3.1 and a potassium-sodium ratio of 2:1.

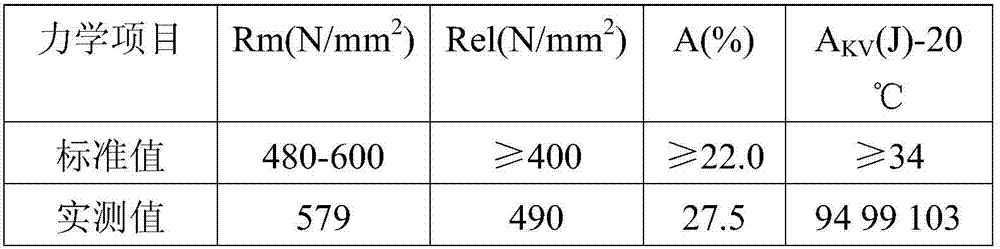

[0045] (3) The submerged arc flux is made according to the above composition for testing. According to the national standard GB / T 12470-2003, with submerged arc welding wire H10Mn2 for pressure storage tanks, chemical composition analysis of deposited metal and mechanical performance test of deposited metal . Welding specification: the welding power supply is DC reverse connection, the welding heat input is 18-19KJ / cm, and the interpass temperature is 145-150℃.

[0046] ①Flux type: active flux.

[0047] ②S / P content of flux:

[0048]

[0...

Embodiment 3

[0055] (1) The weight parts of various raw materials in the flux powder are as follows: (parts)

[0056] Calcium Oxide Magnesium Oxide Aluminum oxide Calcium fluoride Barium fluoride Rutile 620208912.5 Manganese Ore Powder Manganese Metal Ferrosilicon alloy Ferromolybdenum alloy Ferro Titanium Ferro Boron 7.57531.70.3

[0057] (2) The binder is high-modulus potassium sodium water glass with a modulus of 3.0-3.1 and a potassium-sodium ratio of 2:1.

[0058] (3) The submerged arc flux is made according to the above composition for testing. According to the national standard GB / T 12470-2003, with submerged arc welding wire H10Mn2 for pressure storage tanks, chemical composition analysis of deposited metal and mechanical performance test of deposited metal . Welding specification: the welding power supply is DC reverse connection, the welding heat input is 18-19KJ / cm, and the interpass temperature is 145-150℃.

[0059] ①Flux type: active flux.

[0060] ②S / P content of flux:

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com