Special submerged arc horizontal welding flux for pressure-bearing storage tank

A pressurized storage tank and flux technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high price, achieve the effect of improving intergranular structure, improving comprehensive performance and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) The parts by weight of various raw materials in the flux powder are as follows: (parts)

[0031] (2) The binder is high modulus potassium sodium water glass with a modulus of 3.0-3.1 and a ratio of potassium to sodium of 2:1.

[0032] (3) The submerged arc welding flux is made according to the above components for testing. According to the national standard GB / T 12470-2003, with the submerged arc welding wire H10Mn2 for pressure storage tanks, the chemical composition analysis of the deposited metal and the mechanical performance test of the deposited metal are carried out. . Welding specification: The welding power supply is DC reverse connection, the welding heat input is 18-19KJ / cm, and the interpass temperature is 145-150°C.

[0033] ① Flux type: active flux.

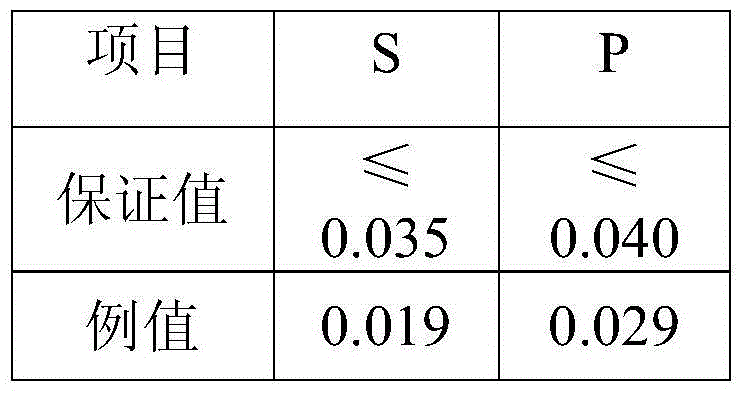

[0034] ②Solder S / P content:

[0035] project

[0036] ③Chemical composition of deposited metal

[0037] project

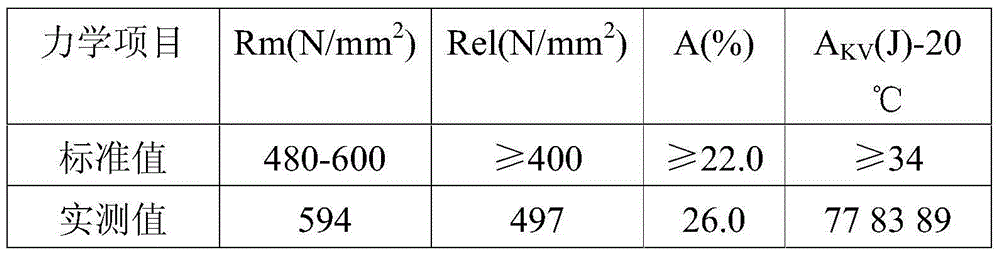

[0038] ④ Measured values of ...

Embodiment 2

[0042] (1) The parts by weight of various raw materials in the flux powder are as follows: (parts)

[0044] (2) The binder is high modulus potassium sodium water glass with a modulus of 3.0-3.1 and a ratio of potassium to sodium of 2:1.

[0045] (3) The submerged arc welding flux is made according to the above components for testing. According to the national standard GB / T 12470-2003, with the submerged arc welding wire H10Mn2 for pressure storage tanks, the chemical composition analysis of the deposited metal and the mechanical performance test of the deposited metal are carried out. . Welding specification: The welding power supply is DC reverse connection, the welding heat input is 18-19KJ / cm, and the interpass temperature is 145-150°C.

[0046] ① Flux type: active flux.

[0047] ②Solder S / P content:

[0048]

[0049] ③Chemical composition of deposited metal

[0050] project

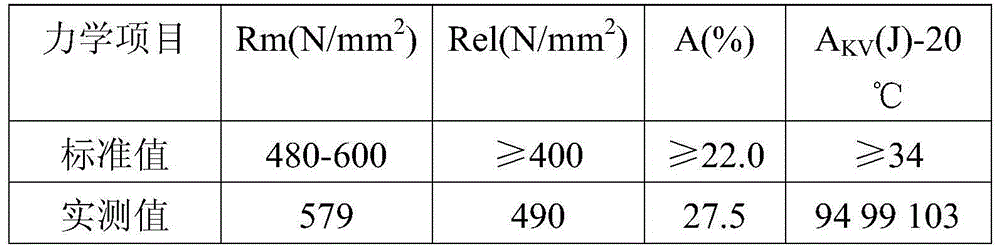

[0051] ④ Measured values of mechanical prope...

Embodiment 3

[0055] (1) The parts by weight of various raw materials in the flux powder are as follows: (parts)

Aluminum oxide

6

20

20

8

9

12.5

Manganese ore powder

ferrosilicon alloy

Ferro-titanium alloy

Ferro-boron alloy

7.5

7

5

3

1.7

0.3

[0057] (2) The binder is high modulus potassium sodium water glass with a modulus of 3.0-3.1 and a ratio of potassium to sodium of 2:1.

[0058] (3) The submerged arc welding flux is made according to the above components for testing. According to the national standard GB / T 12470-2003, with the submerged arc welding wire H10Mn2 for pressure storage tanks, the chemical composition analysis of the deposited metal and the mechanical performance test of the deposited metal are carried out. . Welding specification: Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com