Thick-wall large-diameter high-grade pipeline steel for increasing low-temperature toughness and manufacturing method thereof

A technology of low temperature toughness and manufacturing method, applied in the field of iron and steel metallurgy, can solve the problem that the low temperature toughness cannot be improved, the fine bainite true ferrite structure cannot be formed, the core band structure cannot be effectively eliminated, and the strength, Uniform fine-grained structure with higher toughness, etc., to reduce the number of phosphorus removal passes, solve manufacturing difficulties, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

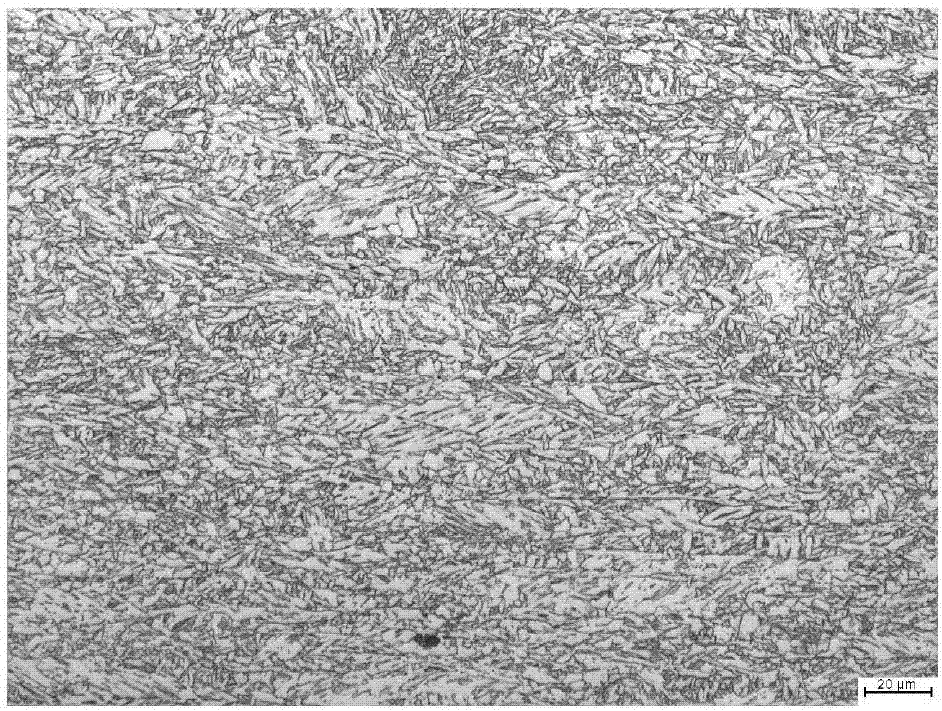

Embodiment 1

[0020] This embodiment is a method for manufacturing thick-walled, large-diameter, high-grade pipeline steel with improved low-temperature toughness, including the following steps:

[0021] (1) The weight percentage composition of the thick-walled large-diameter high-grade pipeline steel with low temperature toughness is: C: 0.039%, Si: 0.19%, Mn: 1.68%, P: 0.006%, S: 0.002%, Al: 0.025% , Nb: 0.051%, Ti: 0.0016%, Cr: 0.15%, Mo: 0.19%, Cu: 0.12%, Ni: 0.27%, Ca: 0.0015%, the balance is Fe and unavoidable impurities;

[0022] (2) Using a slab with a thickness of 320mm, the heating temperature of the slab is 1155°C, the heating time is 10.3min / cm in the thickness of the slab, and the soaking time is 56min;

[0023] (iii) 2 passes for phosphorus removal, including 1 pass for rough rolling and 1 pass for finish rolling;

[0024] (iv) Increase the reduction rate of the final pass of rough rolling, the reduction rate of the final pass of rough rolling is greater than 25%, and the thi...

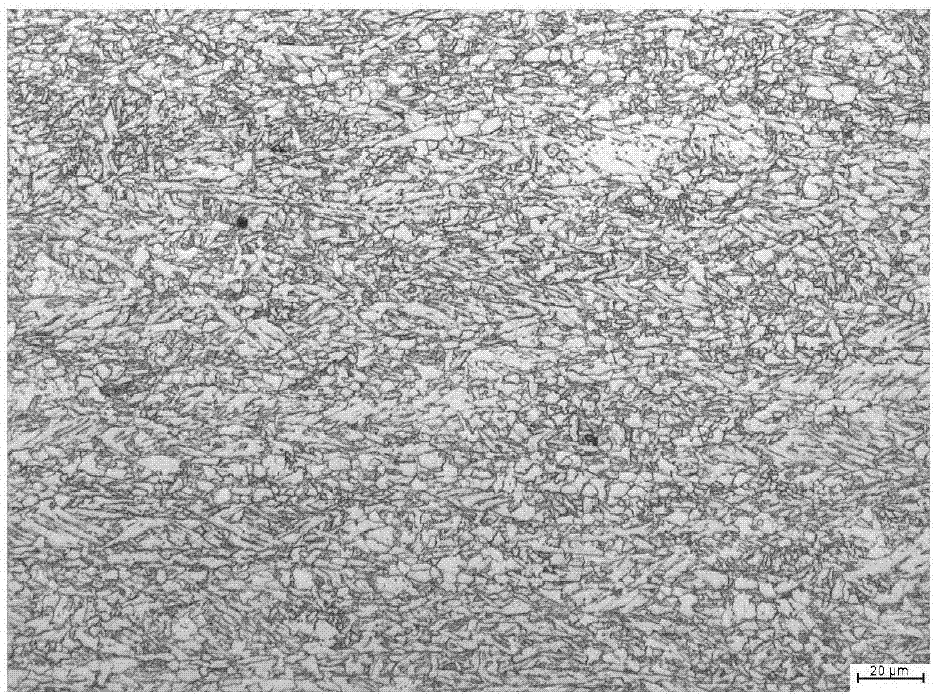

Embodiment 2

[0030] This embodiment is a method for manufacturing thick-walled, large-diameter, high-grade pipeline steel with improved low-temperature toughness, including the following steps:

[0031] (1) The weight percentage composition of the thick-walled large-diameter high-grade pipeline steel with low temperature toughness is: C: 0.043%, Si: 0.217%, Mn: 1.66%, P: 0.006%, S: 0.001%, Al: 0.020% , Nb: 0.052%, Ti: 0.009%, Cr: 0.13%, Mo: 0.17%, Cu: 0.15%, Ni: 0.26%, Ca: 0.001%, the balance is Fe and unavoidable impurities;

[0032] (2) Using a slab with a thickness of 320mm, the heating temperature of the slab is 1167°C, the heating time is 11min / cm in the thickness of the slab, and the soaking time is 58min;

[0033] (iii) 2 passes for phosphorus removal, including 1 pass for rough rolling and 1 pass for finish rolling;

[0034] (iv) Increase the reduction rate of the final pass of rough rolling, the reduction rate of the final pass of rough rolling is greater than 25%, and the thickn...

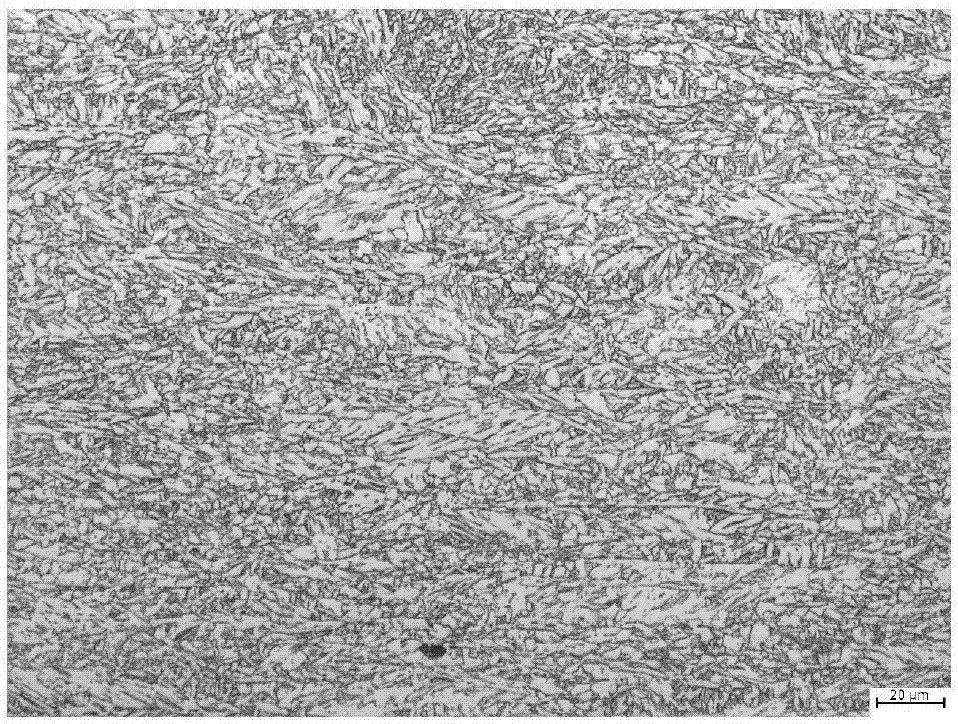

Embodiment 3

[0040] This embodiment is a method for manufacturing thick-walled, large-diameter, high-grade pipeline steel with improved low-temperature toughness, including the following steps:

[0041] (1) The weight percentage composition of the thick-walled large-diameter high-grade pipeline steel with low temperature toughness is: C: 0.044%, Si: 0.218%, Mn: 1.67%, P: 0.007%, S: 0.002%, Al: 0.036% , Nb: 0.054%, Ti: 0.011%, Cr: 0.12%, Mo: 0.17%, Cu: 0.13%, Ni: 0.28%, Ca: 0.0020%, the balance is Fe and unavoidable impurities;

[0042] (2) Using a slab with a thickness of 320mm, the heating temperature of the slab is 1158°C, the heating time is 12min / cm in the thickness of the slab, and the soaking time is 57min;

[0043] (iii) 2 passes for phosphorus removal, including 1 pass for rough rolling and 1 pass for finish rolling;

[0044] (iv) Increase the reduction rate of the final pass of rough rolling, the reduction rate of the final pass of rough rolling is greater than 25%, and the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com