Gap-free large screwdown device for roller gap and using method thereof

A pressing device and no gap technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as large roll gap deviation and production impact, to eliminate center segregation, improve casting billet quality, eliminate The effect of loose center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

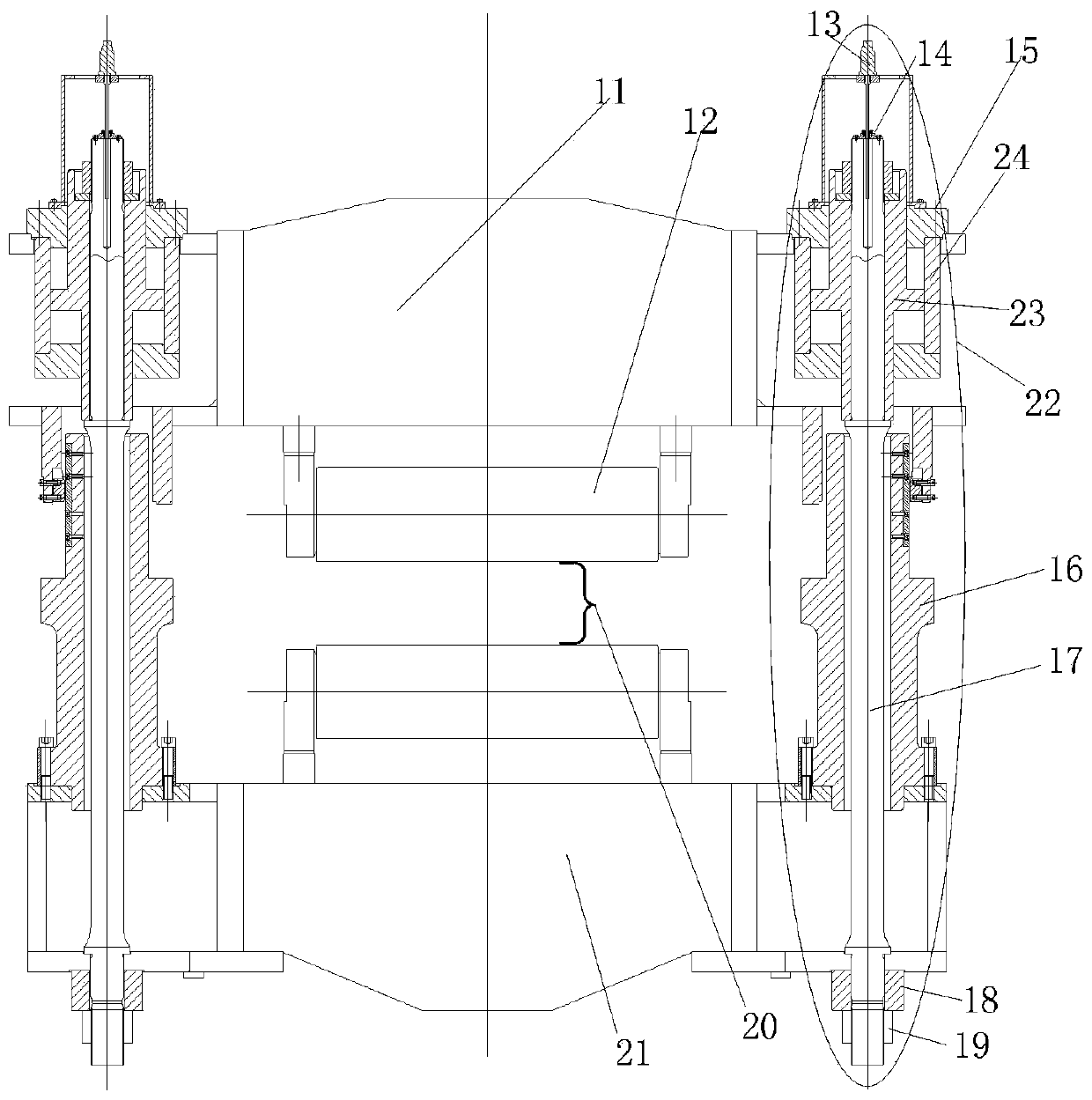

[0029] Such as figure 1 As shown, a large gapless rolling device for rolling gaps includes a lower frame assembly frame 21, and several groups of flexible rod frames are connected to the lower frame assembly frame 21. Each group of flexible rod frames includes two flexible rods 17, two The root flexible rods 17 are respectively located on both sides of the lower frame assembly frame 21, and the upper end of each flexible rod 17 is connected with a hollow hydraulic cylinder 15, and the bottom of the piston 23 of the hollow hydraulic cylinder 15 is connected with the flexible rod 17, and the hollow hydraulic cylinders 15 can be connected to each other. The upper frame assembly frame 11 is disassembled and connected, wherein the displacement sensing device is also connected to the top of the hollow hydraulic cylinder 15, the guide roller 12 is connected above the lower frame assembly frame 21, and the guide roller 12 is connected below the upper frame assembly frame 11.

[0030]...

Embodiment 2

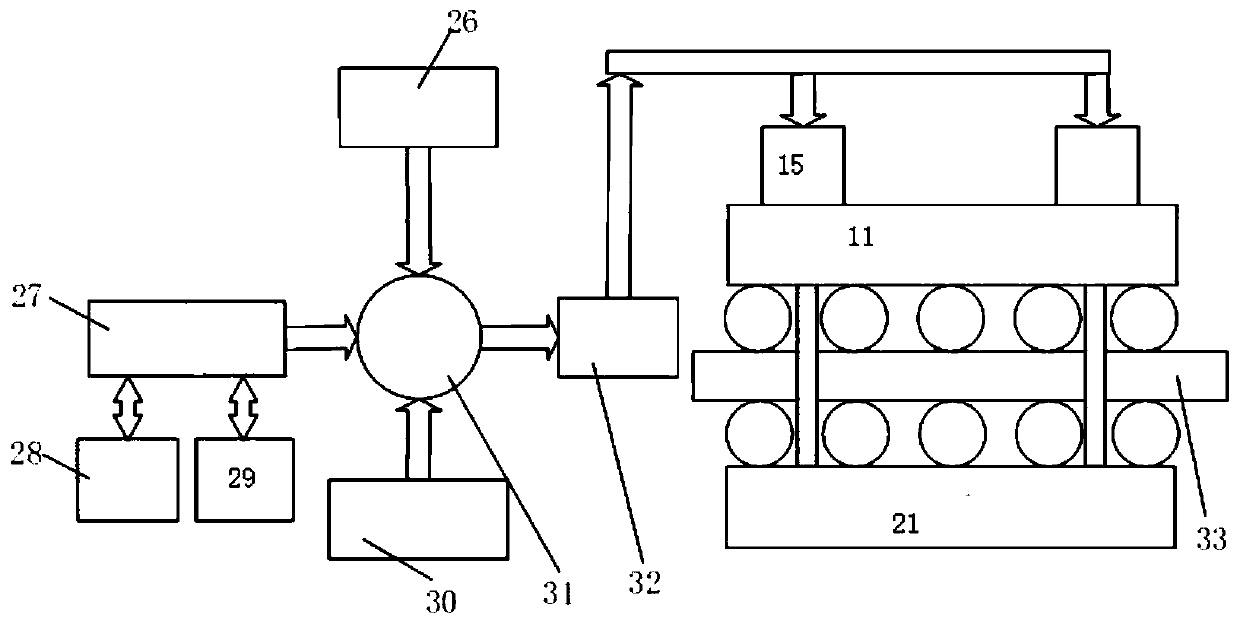

[0041] Such as Figure 1 to Figure 3 As shown, a method for using a gapless large reduction device for a roll gap includes the following steps:

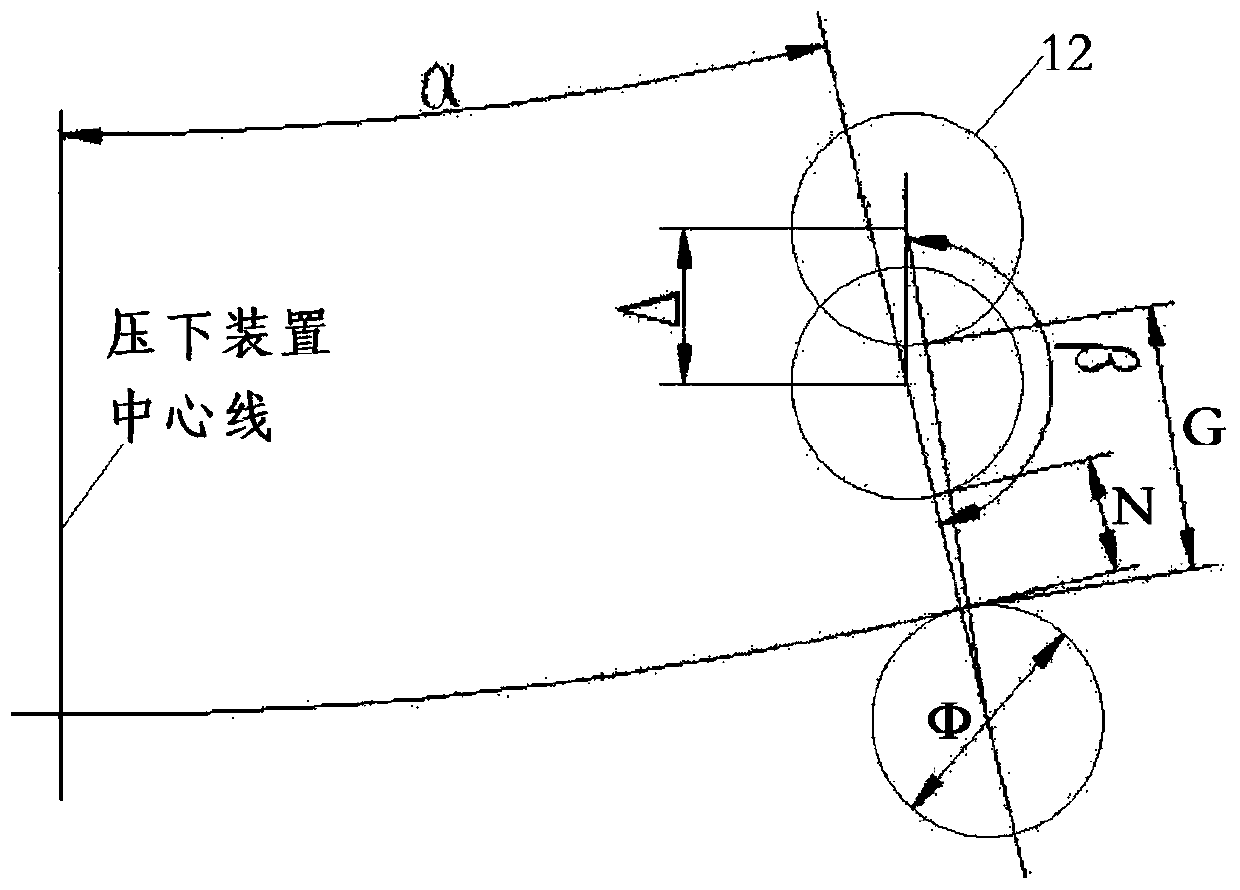

[0042] The first step, data measurement, use the roll gap measuring instrument to measure the actual roll gap value G between the two guide rolls 测 , the neutral roll gap N of the pressing device, the diameter of the guide roll The obtuse angle β of the angle between the center line of the inner and outer arc rollers of the pressing device and the center line of the pressing device,

[0043] Such as image 3 As shown, the neutral roll gap N of the pressing device, the diameter of the guide roll The obtuse angle β of the angle between the center line of the inner and outer arc rollers of the pressing device and the center line of the pressing device,

[0044] In the second step, the guide roller moves, and the actual roll gap value G 测 , input to the zero point correction module 29, the zero point correction module 29 calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com