High-strength and high-toughness wind power gear steel and preparation method thereof

A high-strength toughness, gear steel technology, applied in the field of wind power gear steel, can solve the problems of mechanical properties, transverse properties, ductility, toughness and compactness, thin shell thickness at the exit of the crystallizer, and uniform compactness of the as-cast structure. , to achieve the effect of avoiding the risk of broken teeth, balancing strength and toughness, and ensuring castability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

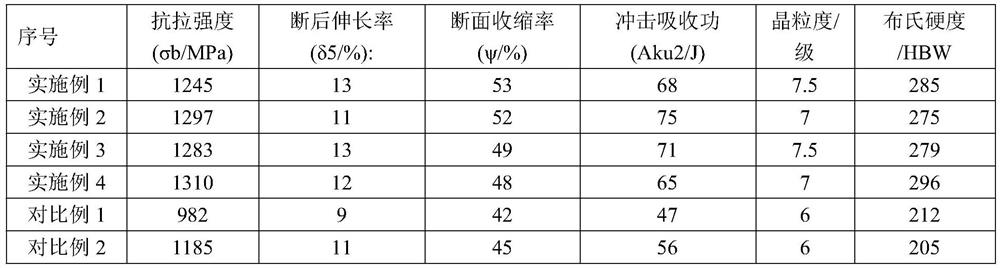

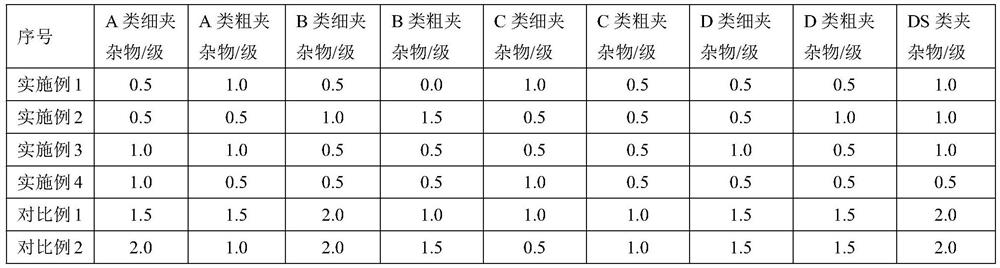

Examples

Embodiment 1

[0029] A preferred embodiment of the high-strength and toughness wind power gear steel of the invention, the chemical composition of the gear steel is: C: 0.12%, Si: 0.35%, Mn: 1.9%, Cr: 0.85%, Mo: 1.23%, Ni: 0.65%, V: 0.13%, B: 0.004%, P: 0.01%, S: 0.005%, Cu: 0.008%, Al: 0.008%, Ti: 0.005%, N: 0.008%, O: 0.001%, the balance is Fe and inevitable impurity elements; its preparation method includes the following steps:

[0030] S1, molten steel smelting: add molten iron and steel through KR pretreatment to BOF oxygen blowing and decarburization treatment for smelting, add slag material to the slag layer during the oxidation period to make slag, and select CaO and SiO as the slag material. 2 , control the basicity of the converter slag slag to be 2.8-3, the carbon content at the end point is ≥ 0.12%, blow argon and stir in the whole process of tapping, control the tapping temperature to 1550 ℃ ~ 1680 ℃, and stop the slag and tap to obtain molten steel;

[0031] S2. Refining and ...

Embodiment 2

[0038] A preferred embodiment of the high strength and toughness wind power gear steel of the invention, the chemical composition of the gear steel in terms of mass percentage is: C: 0.19%, Si: 0.24%, Mn: 2%, Cr: 0.64%, Mo : 0.89%, Ni: 0.45%, V: 0.18%, B: 0.003%, P: 0.015%, S: 0.015%, Cu: 0.005%, Al: 0.003%, Ti: 0.007%, N: 0.008%, O : 0.001%, the balance is Fe and inevitable impurity elements; the preparation method includes the following steps:

[0039] S1, molten steel smelting: add molten iron and steel through KR pretreatment to BOF oxygen blowing and decarburization treatment for smelting, add slag material to the slag layer during the oxidation period to make slag, and select CaO and SiO as the slag material. 2 , control the basicity of the converter slag slag to be 2.6-3, the carbon content at the end point is ≥ 0.12%, blow argon and stir during the whole process of tapping, control the tapping temperature to 1570 ° C ~ 1610 ° C, and stop the slag and tap the steel to o...

Embodiment 3

[0047] A preferred embodiment of the high strength and toughness wind power gear steel of the invention, the chemical composition of the gear steel in terms of mass percentage is: C: 0.15%, Si: 0.28%, Mn: 2.3%, Cr: 0.96%, Mo : 0.63%, Ni: 0.7%, V: 0.16%, B: 0.005%, P: 0.002%, S: 0.004%, Cu: 0.006%, Al: 0.008%, Ti: 0.006%, N: 0.004%, O : 0.001%, the balance is Fe and inevitable impurity elements; the preparation method includes the following steps:

[0048] S1, molten steel smelting: add molten iron and steel through KR pretreatment to BOF oxygen blowing and decarburization treatment for smelting, add slag material to the slag layer during the oxidation period to make slag, and select CaO and SiO as the slag material. 2 , control the basicity of the converter slag slag to be 2.6-3.5, the carbon content at the end point is ≥ 0.12%, blow argon and stir in the whole process of tapping, control the tapping temperature to 1650 ℃ ~ 1680 ℃, and tap the slag to obtain molten steel;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com