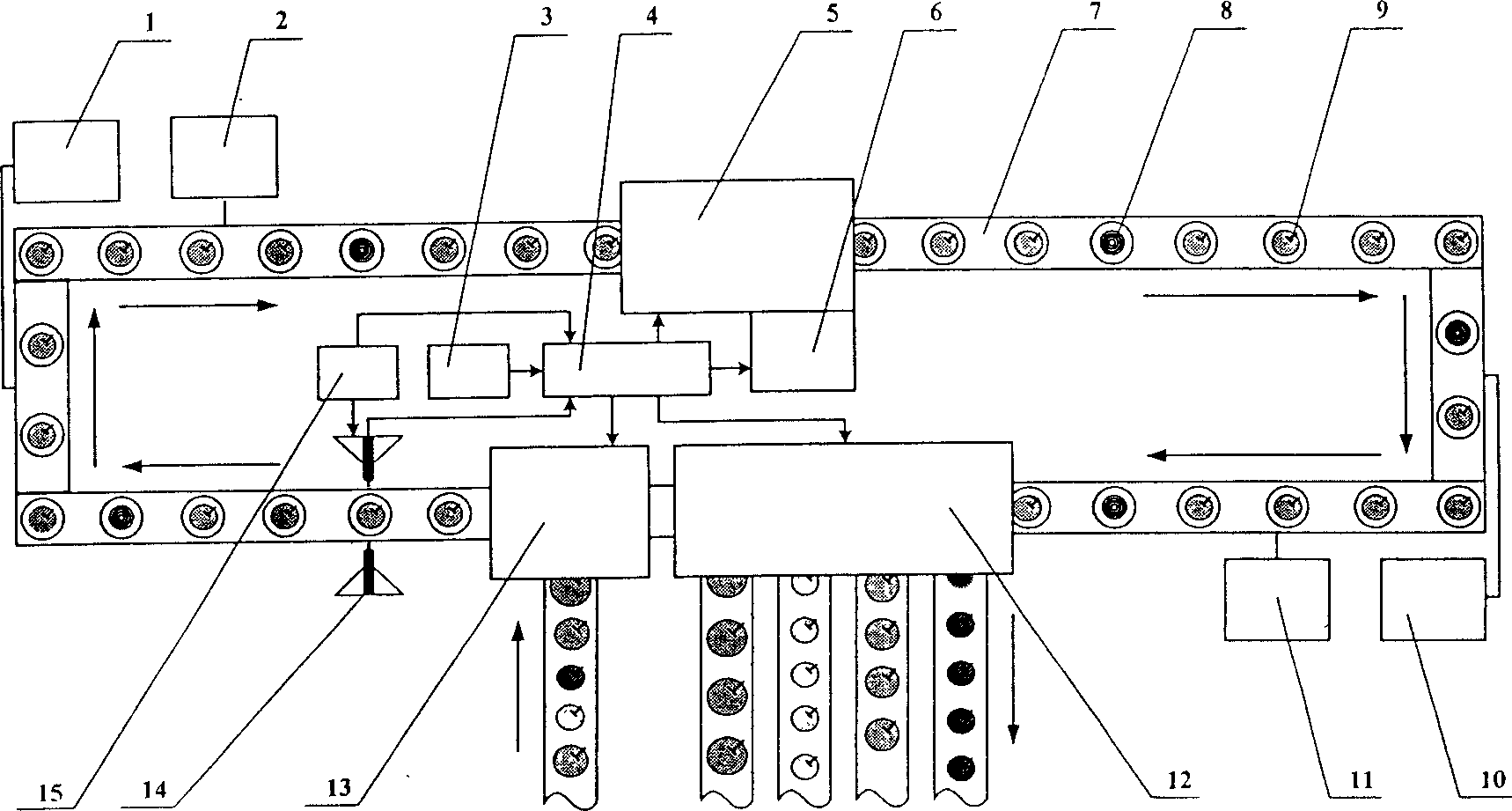

Method and apparatus for non-destructive testing of fruit internal quality based on optical properties

An internal quality, non-destructive testing technology, applied in the measurement of color/spectral characteristics, measuring devices, using optical devices, etc., can solve the problems of large detection errors, different detection positions, inconsistent detection positions, etc., to improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

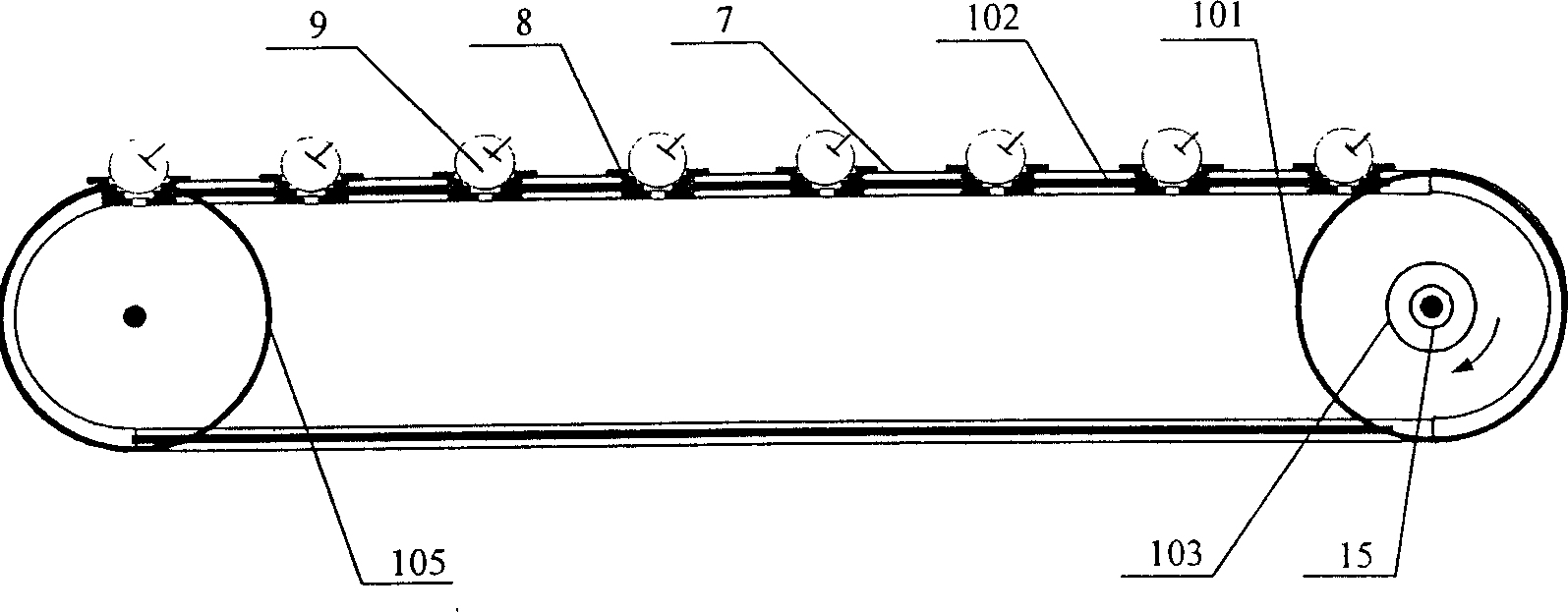

Method used

Image

Examples

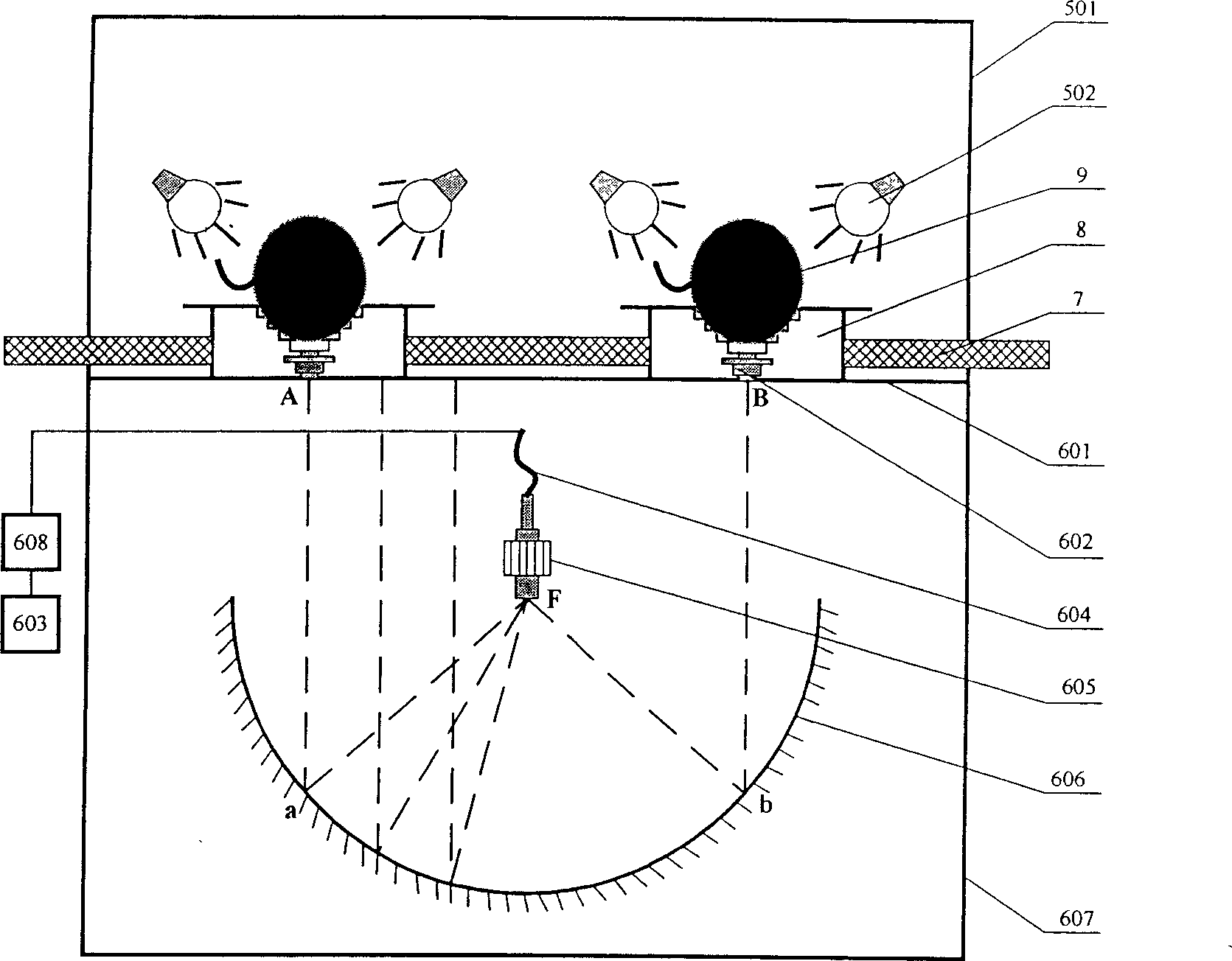

test approach 1

[0061] Detection scheme 1: At the beginning of the detection, the light source irradiates the fruit sample 9 to be tested, the irradiated light of the light source system 5 is transmitted through the inside of the fruit, and the transmitted light of the fruit sample to be tested passes through the light collimation element 602 installed at the bottom of the tray, and passes through the The slit of the partition 601 is irradiated on the concave reflector 606 in the detection box 607, and the transmitted light is reflected by the concave reflector and then directed to the detection probe 605 located at the focal point F of the concave reflector; because of the movement of the tray 8, the transmitted light is The concave mirror moves, but the reflected transmitted light will be directed to the detection probe at the focal position of the concave mirror. When the tray moves from point A to point B to complete the integration time required for detection, and the integration and sum o...

test approach 2

[0062] Detection scheme 2: at the beginning of the detection, the light source illuminates the fruit sample 9 to be tested, and the light is transmitted through the inside of the fruit. On the plane reflector 609 on the reflector conveyor belt 612 in the detection box 607, the angle between the plane reflector and the horizontal plane is 45 degrees, and the transmitted light is reflected by the plane reflector and shoots to the fixed axis level detection probe 605; because the tray 8, the transmitted light is also moving, according to the moving speed of the pallet, the drive motor 614 of the reflective mirror conveyor belt 612 drives the plane reflector on it to move synchronously with the pallet at the corresponding speed, and the plane reflector always reflects the transmitted light Shooting to the detection probe, when the tray moves from point A to point B to complete the integration time required for detection, and the integration and acquisition of the spectrum are continu...

test approach 3

[0063] Detection scheme 3: at the beginning of the detection, the light source illuminates the fruit sample 9 to be tested, and the light is transmitted through the inside of the fruit. On the rotatable plane mirror 615 in the detection box 607, the transmitted light is reflected by the plane mirror and shoots to the fixed axis level detection probe 605; because of the movement of the tray, the transmitted light is displaced in the horizontal position, in order to make the displacement change The transmitted light will be directed to the detection probe after reflection, requiring the plane mirror to rotate around point O to meet the detection requirements; the rotation of the plane mirror is realized by the mirror rotation drive device 616, when the tray moves from point A to point B to complete the detection The required integration time, and the integration and acquisition of the spectrum are continuous in the whole process; the collected transmitted light is sent to the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com