Method for rapidly detecting tea quality through near infrared technology

A technology in the near-infrared and near-infrared range, applied in the measurement of scattering characteristics, etc., can solve the problems of cumbersome process, long cycle, uneven tea quality, etc., and achieve the effect of avoiding the interference of human factors and achieving objective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

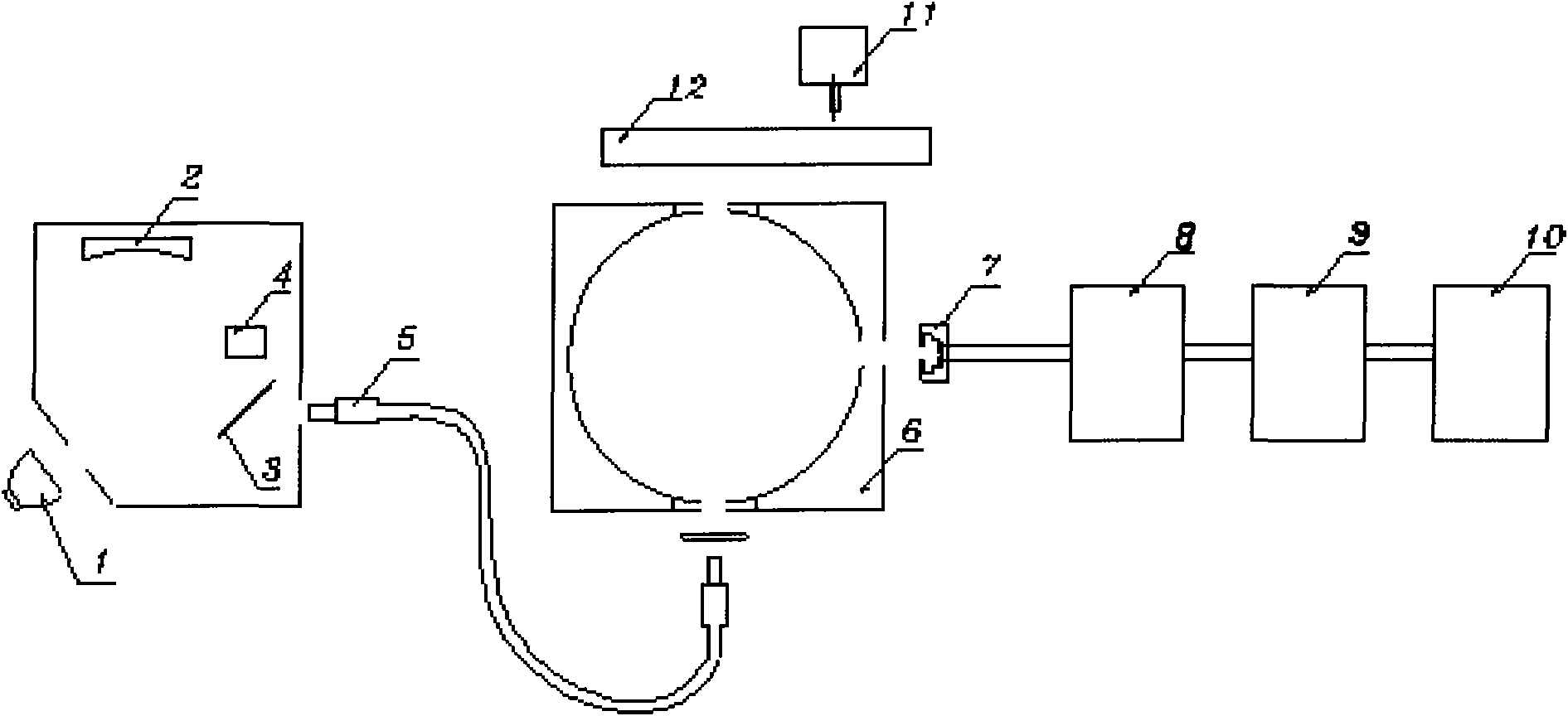

[0030] Such as figure 1 , Near-infrared technology to quickly detect the quality of tea, the device consists of near-infrared light source 1, near-infrared spectroscopy system 2, beam splitter 3, reference near-infrared detector 4, optical fiber 5, diffuse reflection integrating sphere device 6, near-infrared detection It is composed of an amplifier 7, an amplifying converter 8, a data processor 9, a display and recording device 10, a stepping motor 11 and a rotating sample stage 12.

[0031] The near-infrared light source 1 is directly coupled into the near-infrared spectroscopy system 2. After the split monochromatic light passes through the beam splitter 3, it enters the reference near-infrared detector 4 and the optical fiber 5 according to the ratio of 2:8, and then enters the diffuse reflection integrating sphere device 6 ; Among them, the light outlet of the diffuse reflection integrating sphere device 6 is eccentrically installed below the rotating sample table 12. The an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com