Supersonic guide-wave time reversion detection apparatus and method for defect of pipeline

A time-reversal, ultrasonic guided wave technology, used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as limiting the flexibility of guided wave detection methods, difficulty in waveform identification, and difficulty in small defect identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

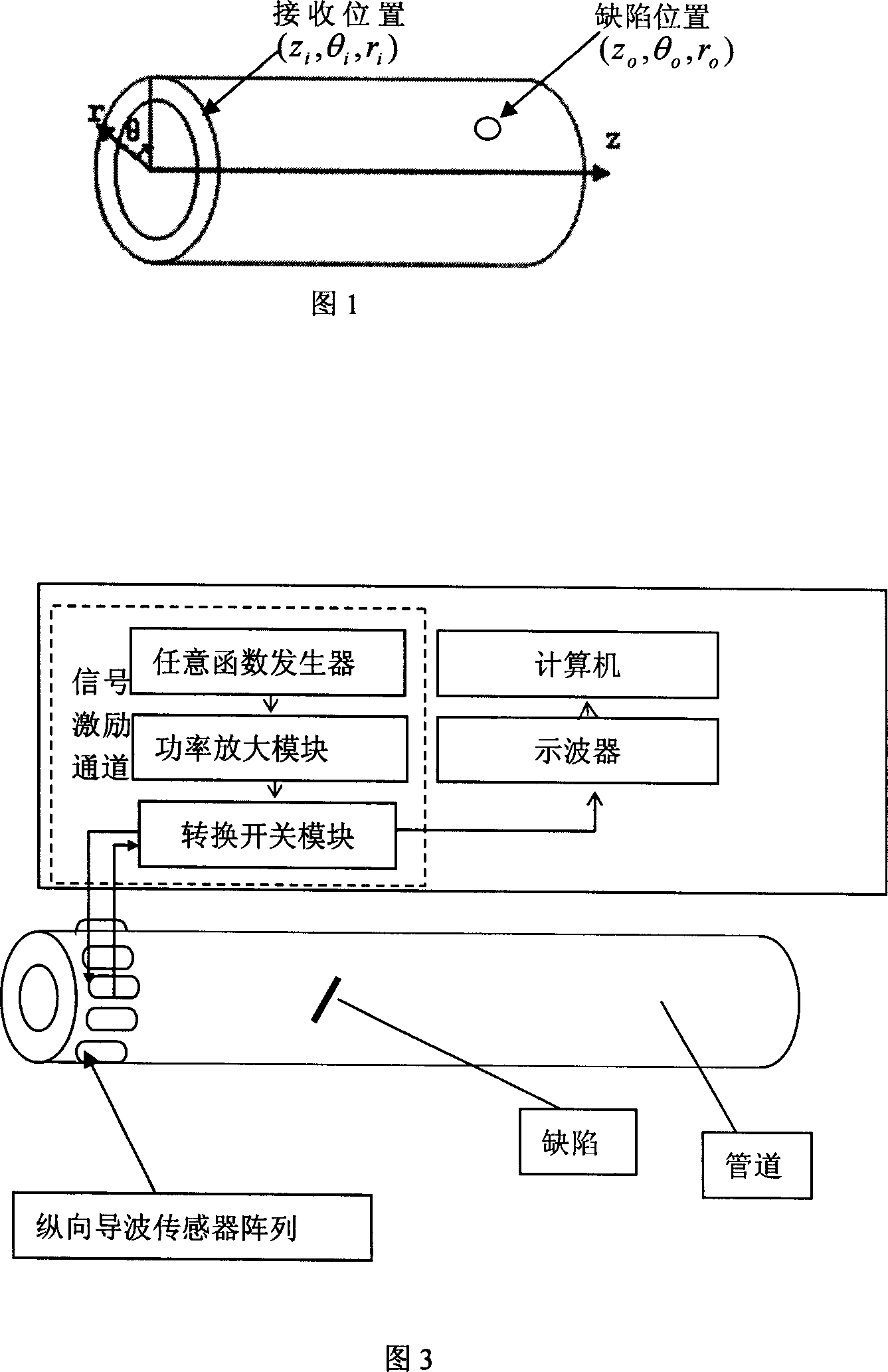

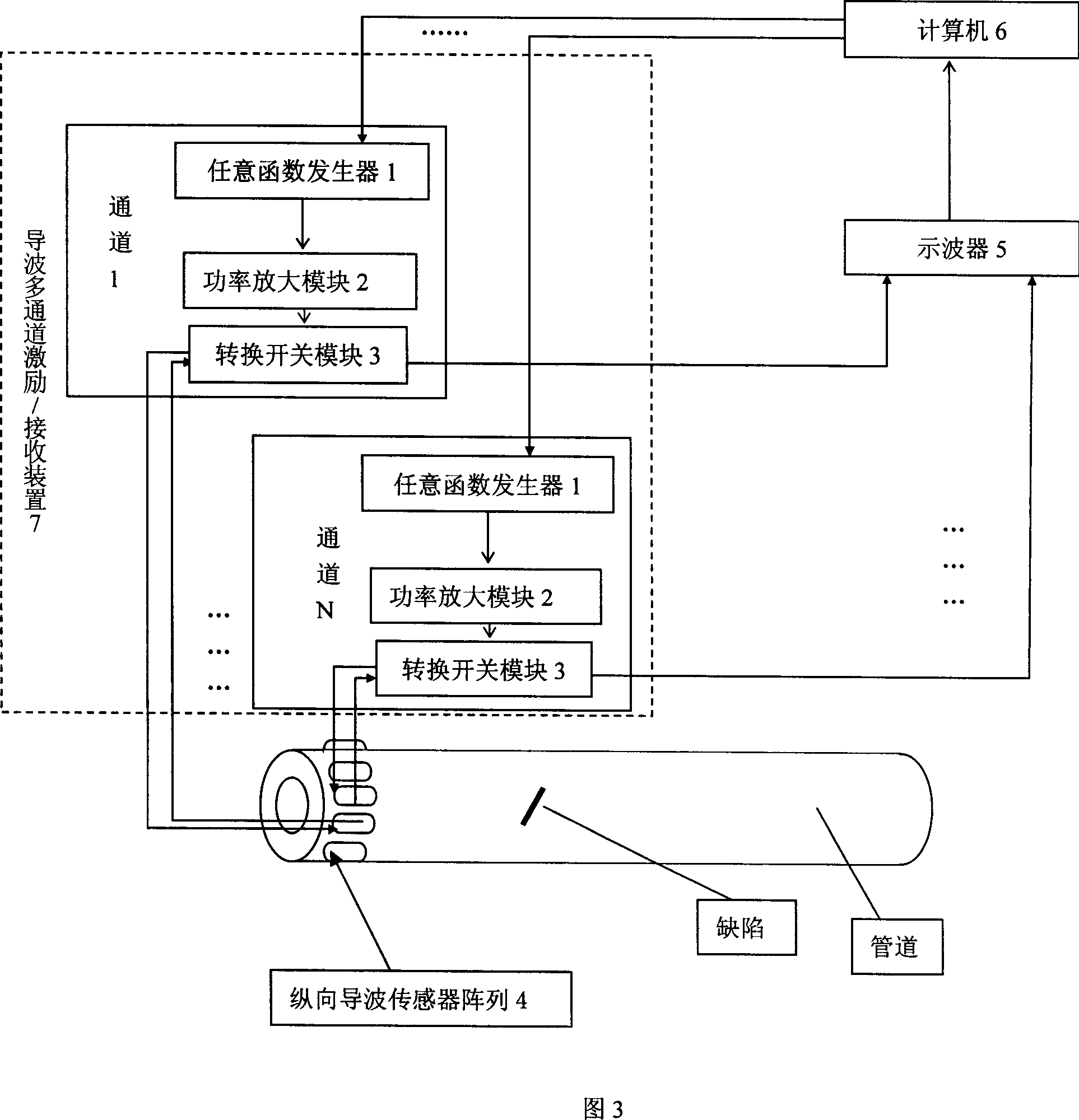

[0056] As shown in Figure 3, the pipeline simulated in this numerical experiment example is a steel pipe with a length of 1.8m, an outer diameter of 70mm, and a wall thickness of 3.5mm. The density is 7932kg / m 3 , the longitudinal wave velocity is 5960m / s, and the transverse wave velocity is 3260m / s.

[0057] Taking the detection process of an oblique crack defect with a length of 35mm, a width of 2mm, and an angle of 45° with the axial direction of the pipeline at a distance of 720mm from the excitation end of the pipeline as an example, the description is as follows.

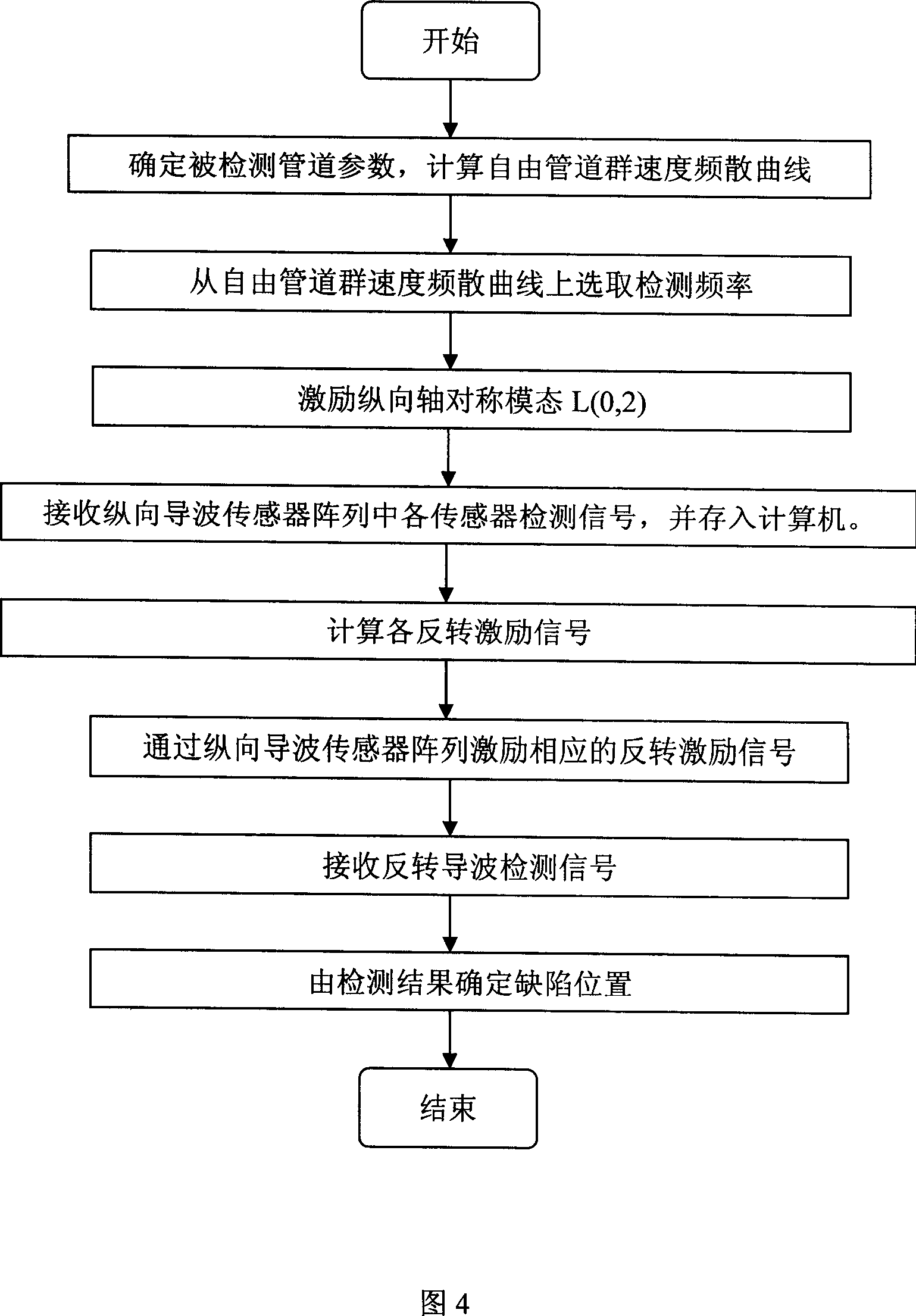

[0058] 1) Calculate the group velocity dispersion curve according to the pipeline parameters, as shown in Figure 5. Select 140kHz as the excitation frequency, and simulate the 48-channel guided wave multi-channel excitation / receiving device 7 by simultaneously loading 5 periods of sinusoidal axial displacement loads plus the Hanning window on 48 nodes at the end of the pipeline near the defect, and The longi...

Embodiment 2

[0067]Embodiment 2 still detects the penetrating oblique crack defect at a distance of 720 mm from the excitation end of the pipeline, with an inclination angle of 45 degrees, a length of 35 mm, and a width of 2 mm. The detection method and steps are exactly the same as those in Embodiment 1, except that the window width T of the signal intercepting rectangular window is different. The window width T in this embodiment ensures that the rectangular window can intercept defect echo information of at least one mode. For the generation of the time-reversed excitation signal, T=0.06 ms is selected according to FIG. 6( a ). And the rectangular window starts to intercept the defect reflection echo signals in the signals received by 48 nodes from the same time starting point of 0.27 ms. Using such a time-reversal excitation signal to obtain the final time-reversal detection signal is shown in Fig. 6(e).

[0068] It can be seen from Embodiment 1 and Embodiment 2 that the time-reversal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com