High-resolution welding seam supersonic image-forming damage-free detection method and detection system

A technology of ultrasonic imaging and non-destructive testing, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, etc. It can solve problems such as high cost, no precedent for combining precision mechanical scanning devices and micro-scanning imaging, complex processing techniques, etc., to improve performance , to achieve computer reproduction, to achieve the effect of a simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail in conjunction with the drawings.

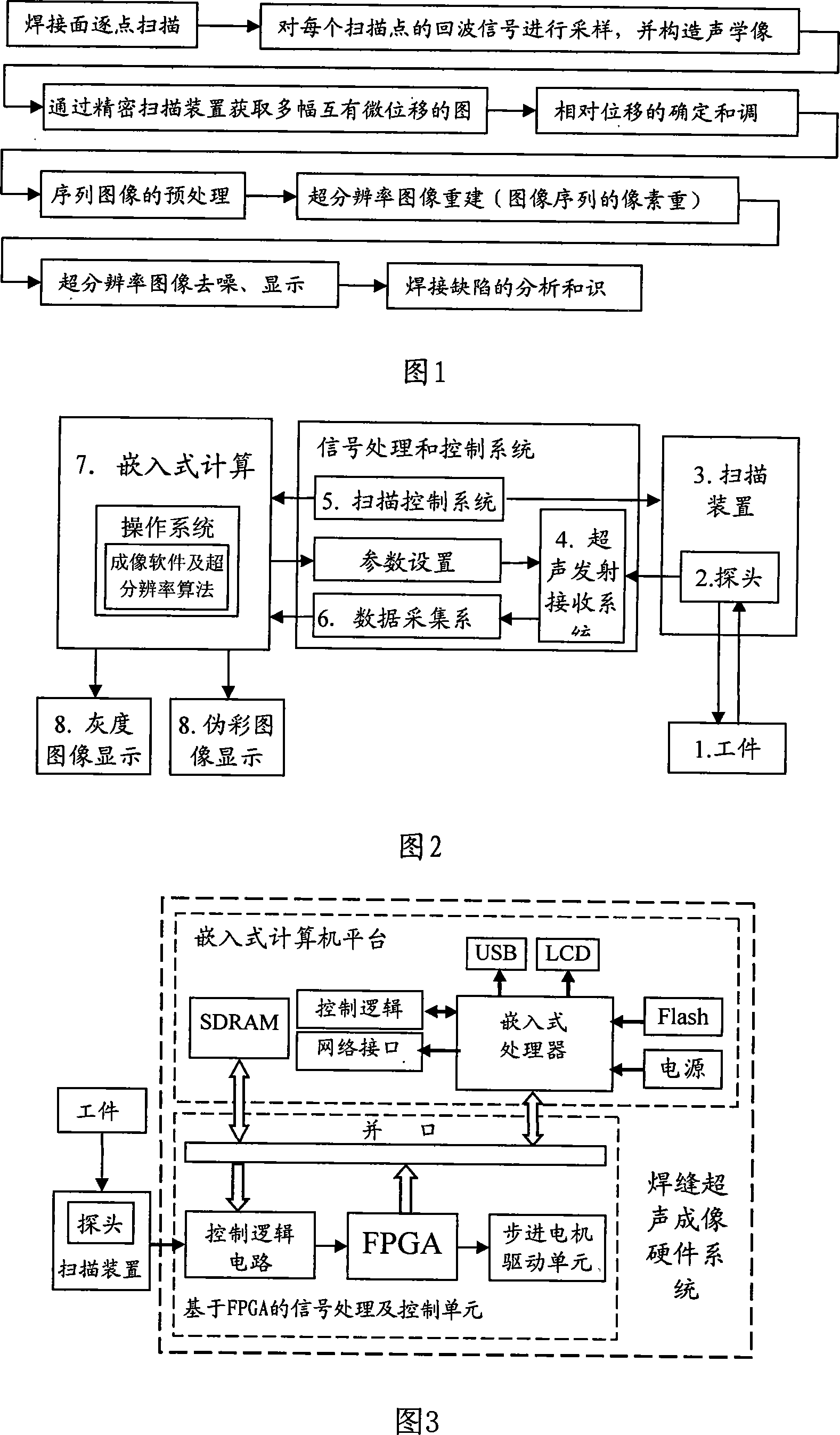

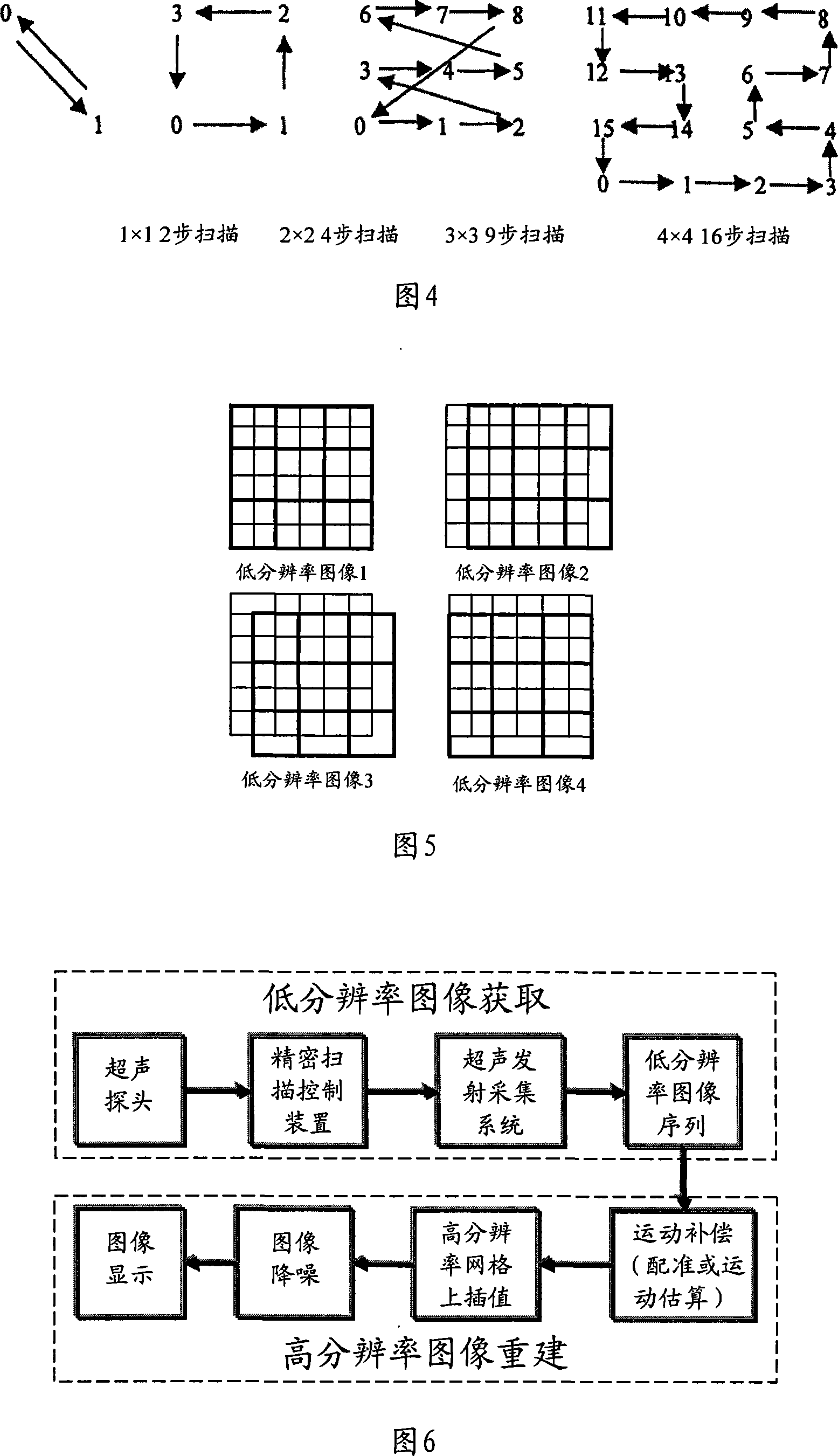

[0027] Fig. 1 shows a working flow chart of a high-definition ultrasonic imaging nondestructive testing method for weld seams, which will be described in three parts in conjunction with the accompanying drawings, namely: ultrasonic imaging inspection of weld seams, micro-scanning and super-resolution reconstruction As well as the Scanning Device and Imaging Software section.

[0028] 1. Weld seam ultrasonic imaging detection part

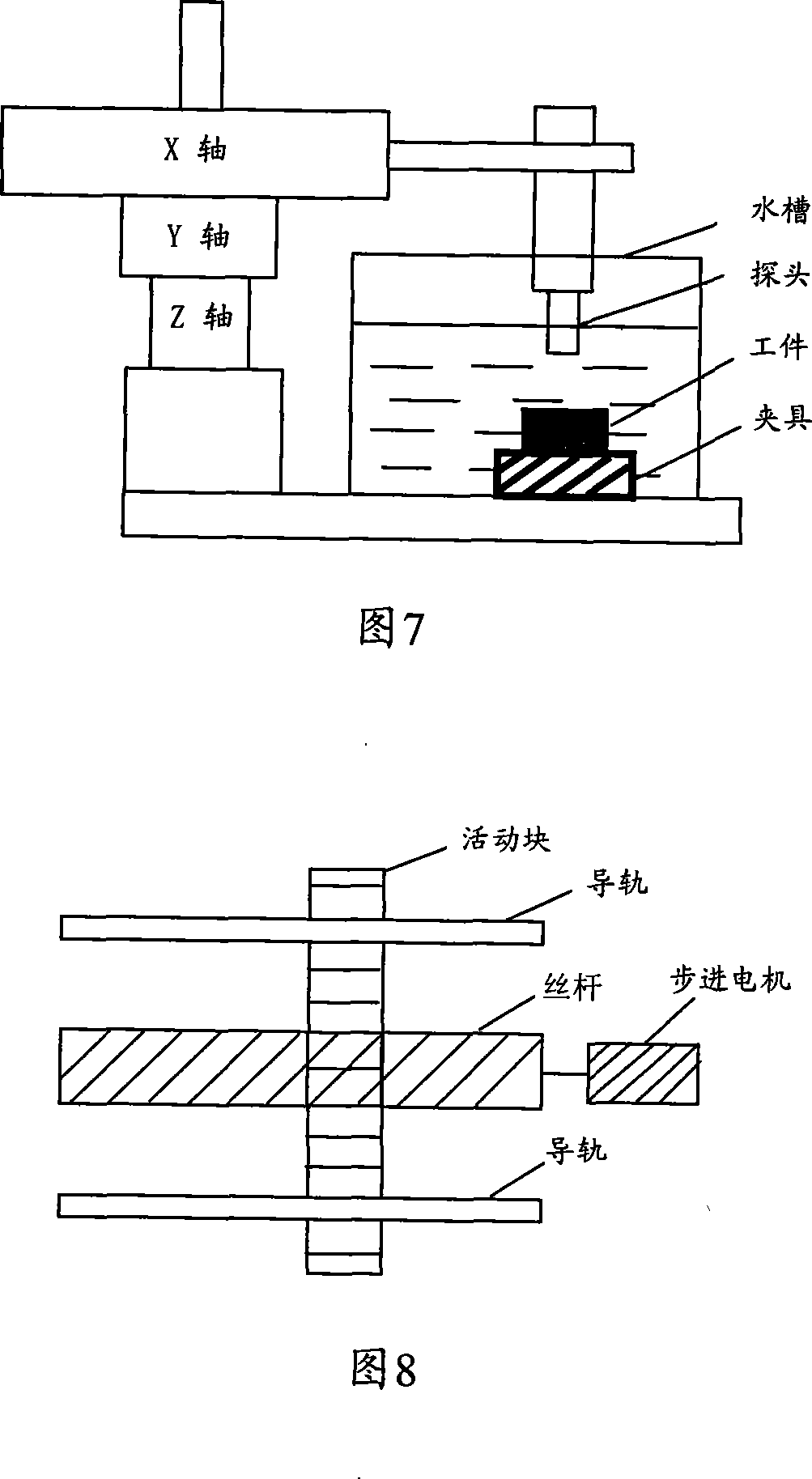

[0029]As shown in Fig. 2, the hardware structure of the welding seam ultrasonic imaging detection system of the present invention, the welding seam workpiece 1 is associated with the data acquisition system 6 through the probe 2, and the data acquisition system 6 passes through the ultrasonic transmitting / receiving system 4 and the scanning device (three-dimensional precision scanning) device) 3, wherein the data acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com