Sub-saturated time-division and multi-frequency magnetic flux leakage testing method

A magnetic flux leakage detection technology with multiple time divisions, applied in the direction of material magnetic variables, etc., can solve the problems of defect depth information, easy to produce misjudgment, corrosion level assessment, etc., and achieve the effect of broad market prospects, high detection accuracy, and simple probe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments.

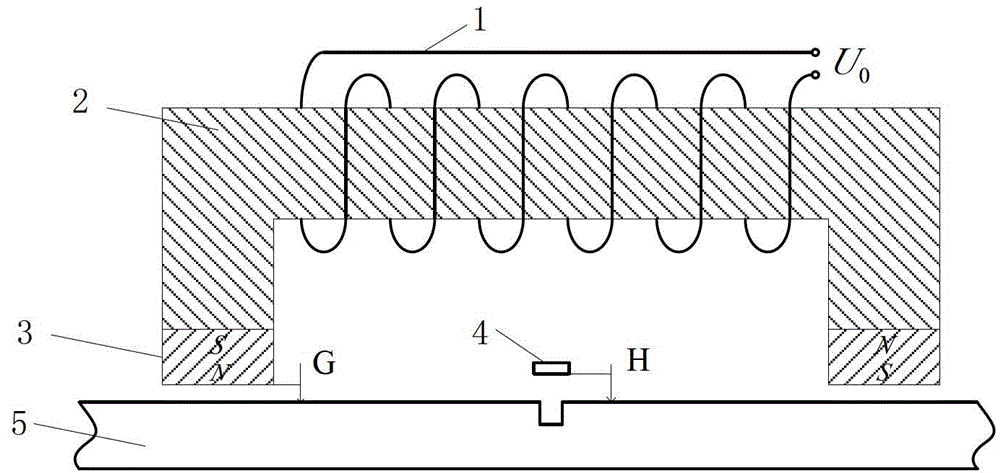

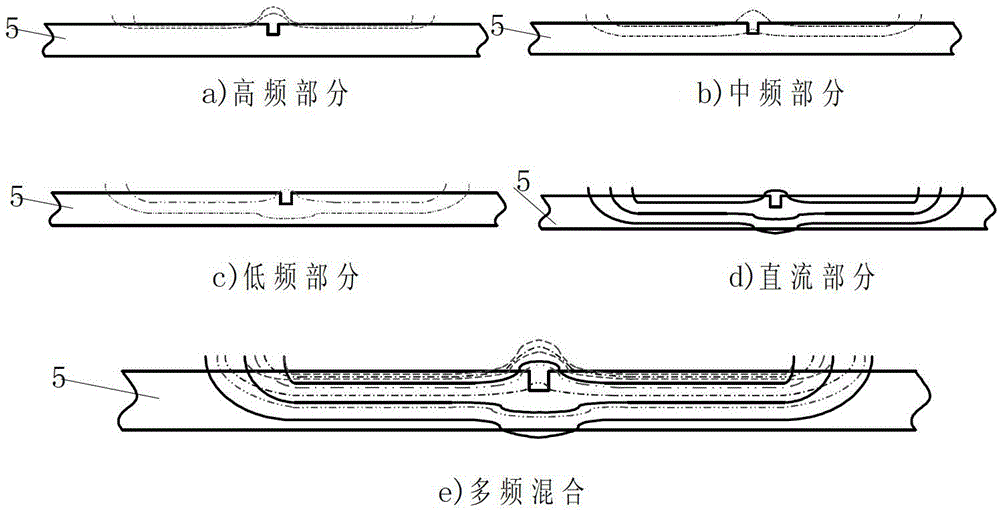

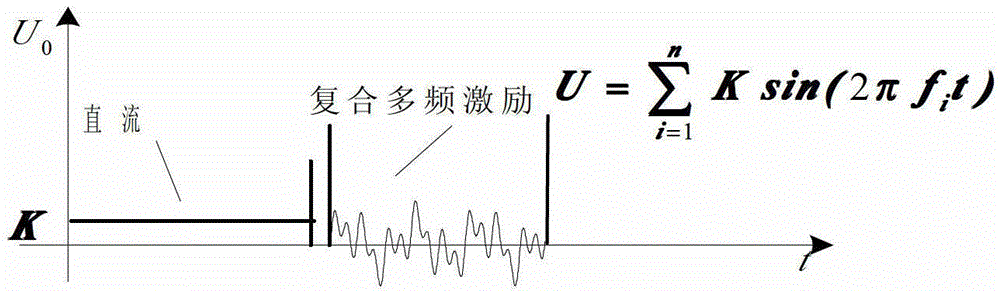

[0032] refer to figure 1 , figure 2 , image 3 and Figure 4 , a half-saturation time-division multi-frequency magnetic flux leakage detection method of the present invention, the magnetizer adopted is composed of a permanent magnet 3 and a U-shaped magnetic core 2 wound with an excitation coil 1, wherein the strength of the permanent magnet 3 is set to measure the steel plate 5 Magnetize to 70-80% of the magnetic saturation state. Therefore, the leakage magnetic field will not be formed on the surface of the steel plate 5 to be tested only by the action of the permanent magnet 3 . Place the magnetizer above the surface of the steel plate 5 to be tested and leave a certain air gap G, the air gap G is 0.5mm-1.5mm, the magnetizer can scan and detect the steel plate 5 to be tested at a certain speed V, and V is 0.2m / s -2m / s. Specific steps are as follows:

[0033] 1) The permanent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com