AC and DC composite magnetisation based leakage detection recognition method for inside and outside wall defect

A composite magnetization and magnetic flux leakage detection technology, which is applied in the direction of material magnetic variables, can solve the problems that the information of the inner and outer walls cannot be determined, and the characteristics of the inner and outer walls cannot be distinguished.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

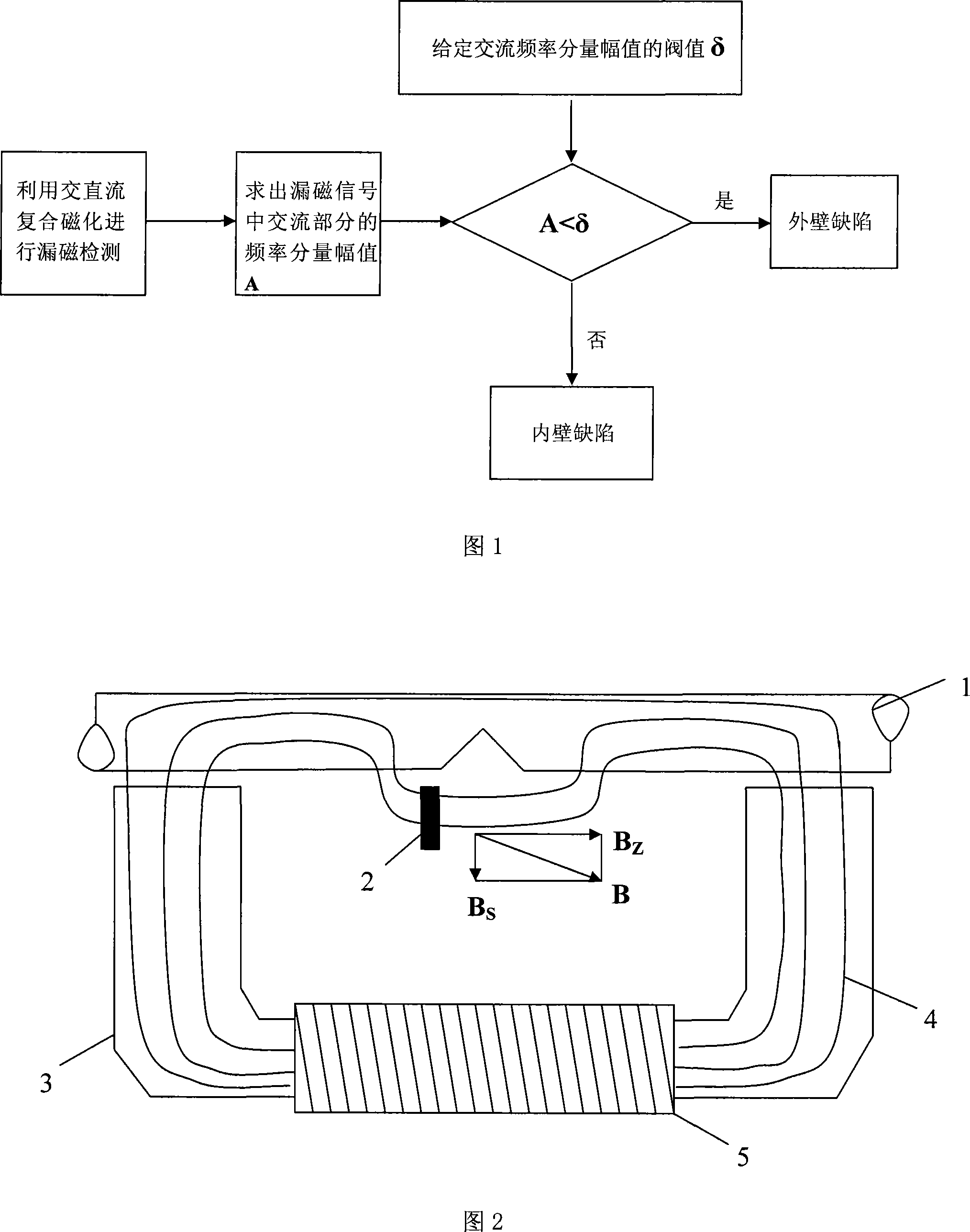

[0020] The identification method of inner and outer wall defects based on the AC-DC composite magnetization MFL detection method mainly includes the following three basic steps: 1) Using the AC-DC composite magnetization method to detect the material MFL; 2) The MFL signal detected by the sensor Spectrum analysis, find out the size of the frequency component of the AC magnetic flux leakage signal in the defective part; 3) Given the threshold value of the AC frequency component, by comparing the AC frequency component of the detected magnetic flux leakage signal with the size of the threshold value, it can be judged that the defect is in the Whether to measure the inner wall or the outer wall of the material.

[0021] Below in conjunction with accompanying drawing, above-mentioned each step is described further:

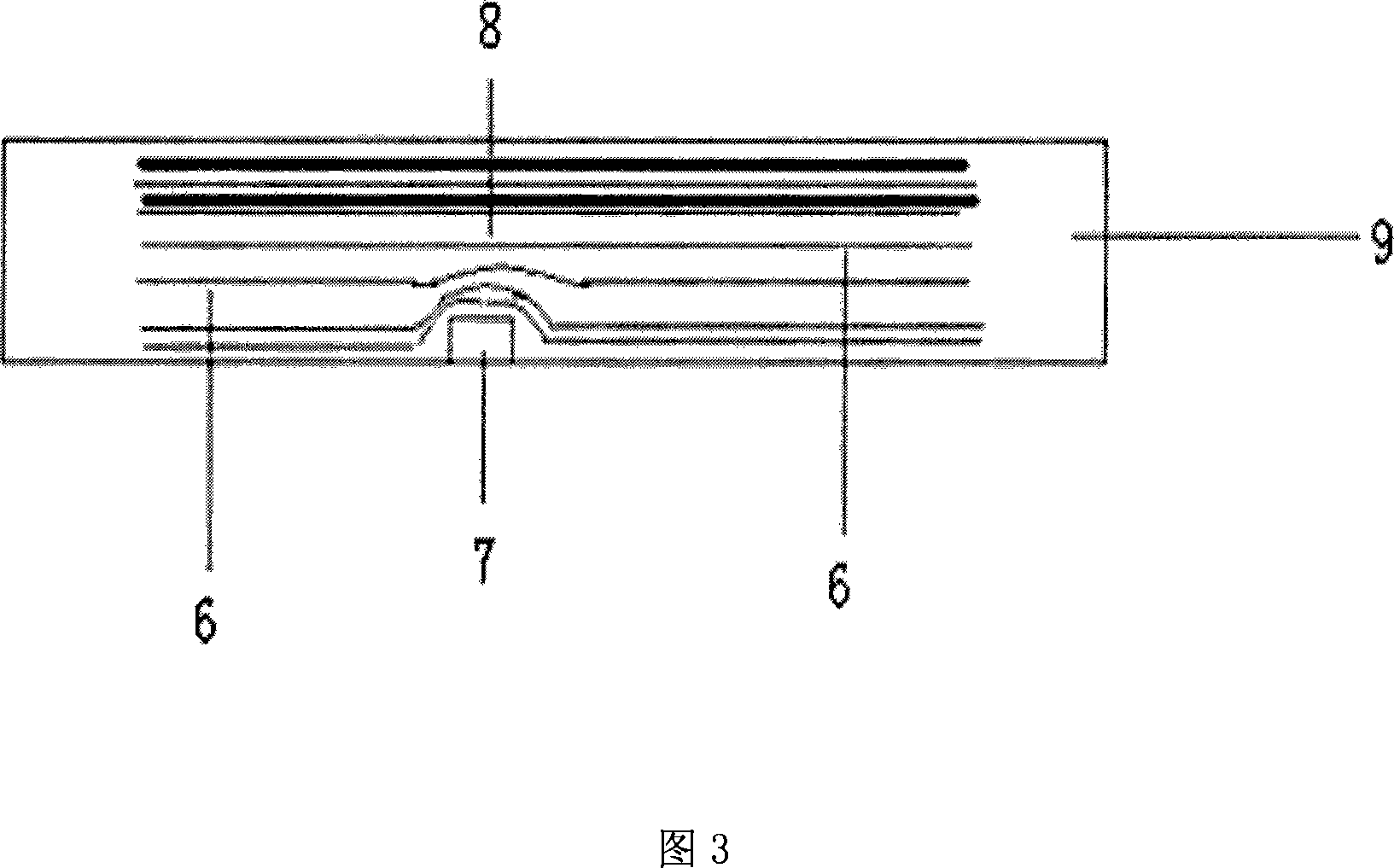

[0022] 1) The basic principle of magnetic flux leakage detection is shown in Figure 2. When the ferromagnetic material to be tested is magnetized, if the material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com