Device and method for detecting defects of inner and outer walls of pipeline based on three-axis magnetic flux leakage and eddy current

A defect detection and eddy current technology, applied in the direction of material magnetic variables, etc., can solve the problems of obvious recognition of near-surface defects and weak identification of internal and external defects, and achieve good detection quality, easy operation, and power saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the invention will be further described below in conjunction with the accompanying drawings.

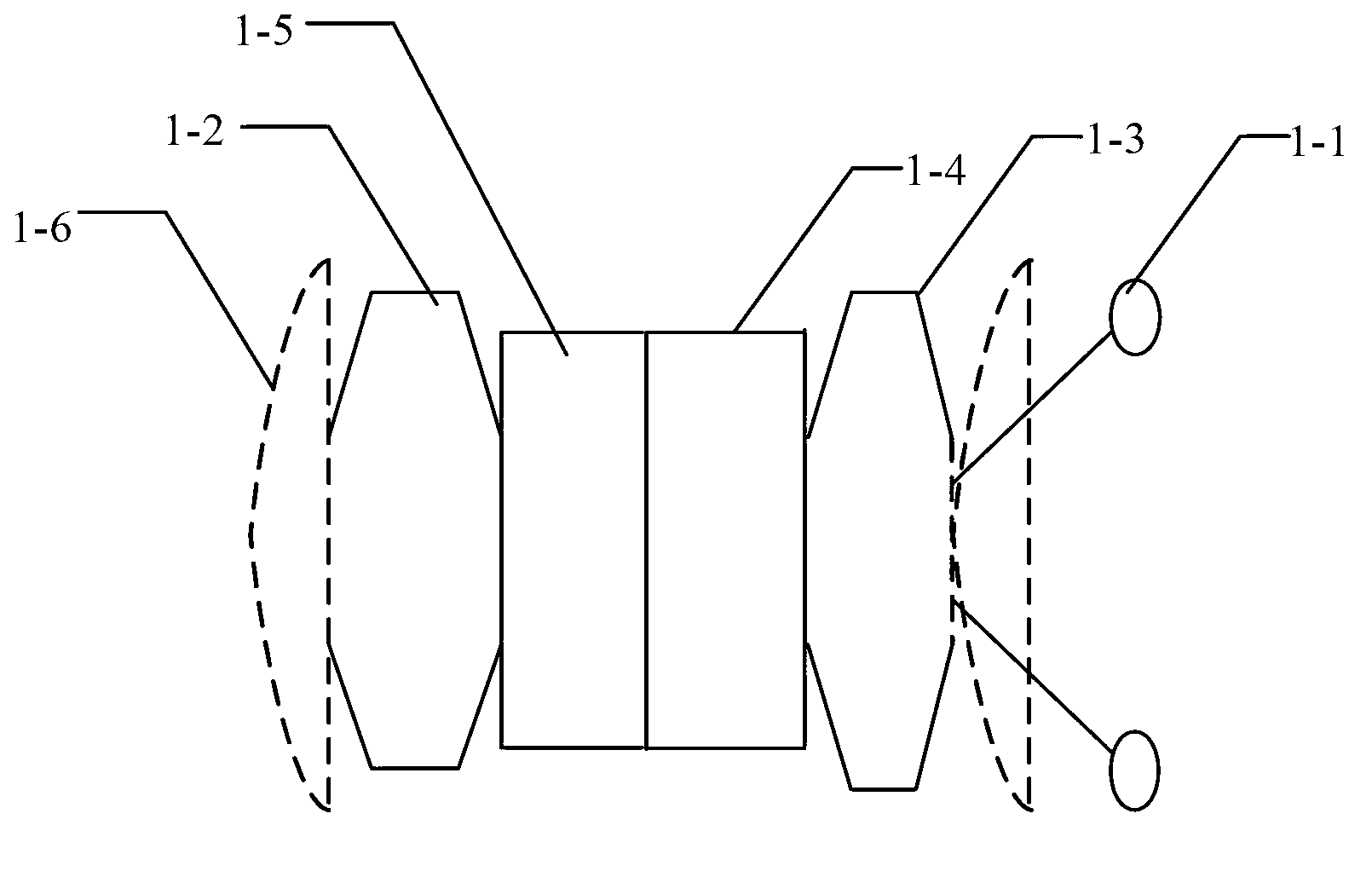

[0027] The device for detecting inner and outer wall defects of pipelines based on three-axis magnetic flux leakage and eddy current adopted in this embodiment has a structure as follows: figure 1 shown. It includes at least three mileage wheels 1-1, a magnetic flux leakage detector 1-2, an eddy current detector 1-3, a data processing and memory 1-4 and a power supply 1-5. The above devices can be packaged in such figure 1 In the structure shown, wherein, the data processing and memory 1-4 is located at the center of the packaging shell, ensuring the balance of the device and the safety of core components; the magnetic flux leakage detector 1-2 is located at the center of the data processing and memory 1-4 On the left side, the eddy current detector 1-3 is located on the right side of the data processing and memory 1-4, and the distance between the magnetic fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com