Permanent magnetic and alternating current direct current composite magnetic flux leakage detecting method

A magnetic flux leakage detection, AC and DC technology, applied in the direction of material magnetic variables, etc., can solve the problems of increasing detection complexity and measurement error, large excitation signal, reducing signal-to-noise ratio, etc., to improve signal-to-noise ratio and measurement accuracy, reduce Interference, the effect of reducing the number of turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

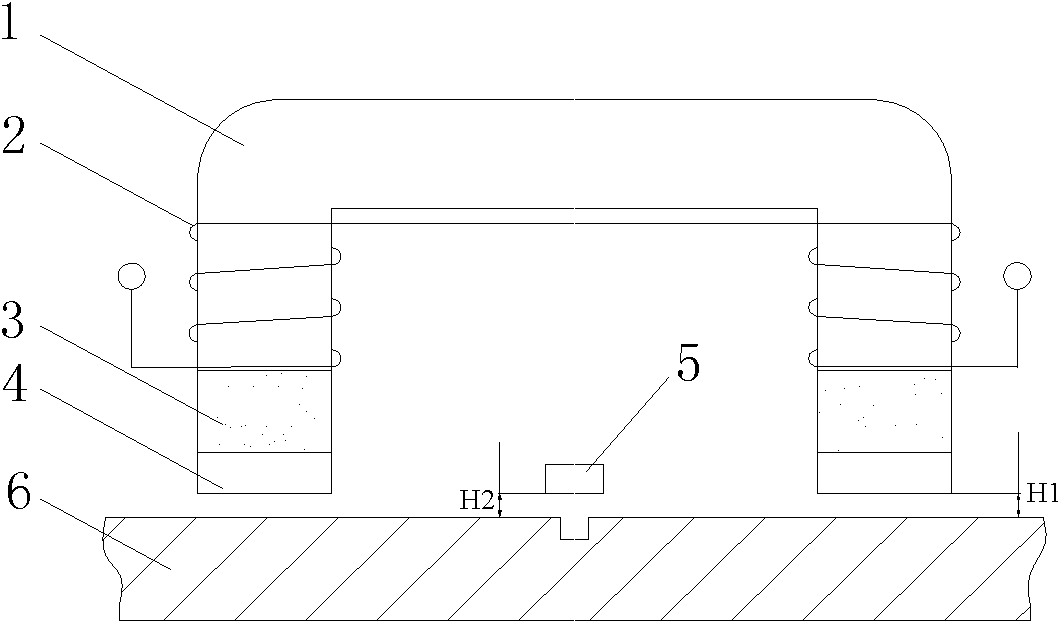

[0029] figure 1 It is the principle diagram of magnetic flux leakage detection combined with permanent magnet and AC and DC. The detection device of the present invention is mainly composed of a U-shaped magnetic core 1 , an excitation coil 2 , a permanent magnet 3 , a pole shoe 4 and a detection element 5 . The excitation coil 2 is wound on both sides of the U-shaped magnetic core 1 and the number of turns of the two excitation coils is equal and the winding directions are opposite. The permanent magnets 3 are fixed on both ends of the U-shaped magnetic core 1 . The pole shoe 4 is fixed under the permanent magnet 3, and with a certain lift-off value H 1 placed above the ferromagnet 6 to be tested. The detection element 5 is fixed in the middle of the two magnetic poles of the magnetizer, and with a certain lift-off value H 2 placed above the ferromagnet 6 to be tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com