Extreme learning machine-based pipeline magnetic flux leakage defect detection method

An extreme learning machine and magnetic flux leakage technology, applied in the direction of material magnetic variables, etc., to achieve the effect of predicting pipeline risks, fast learning speed, and good generalization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

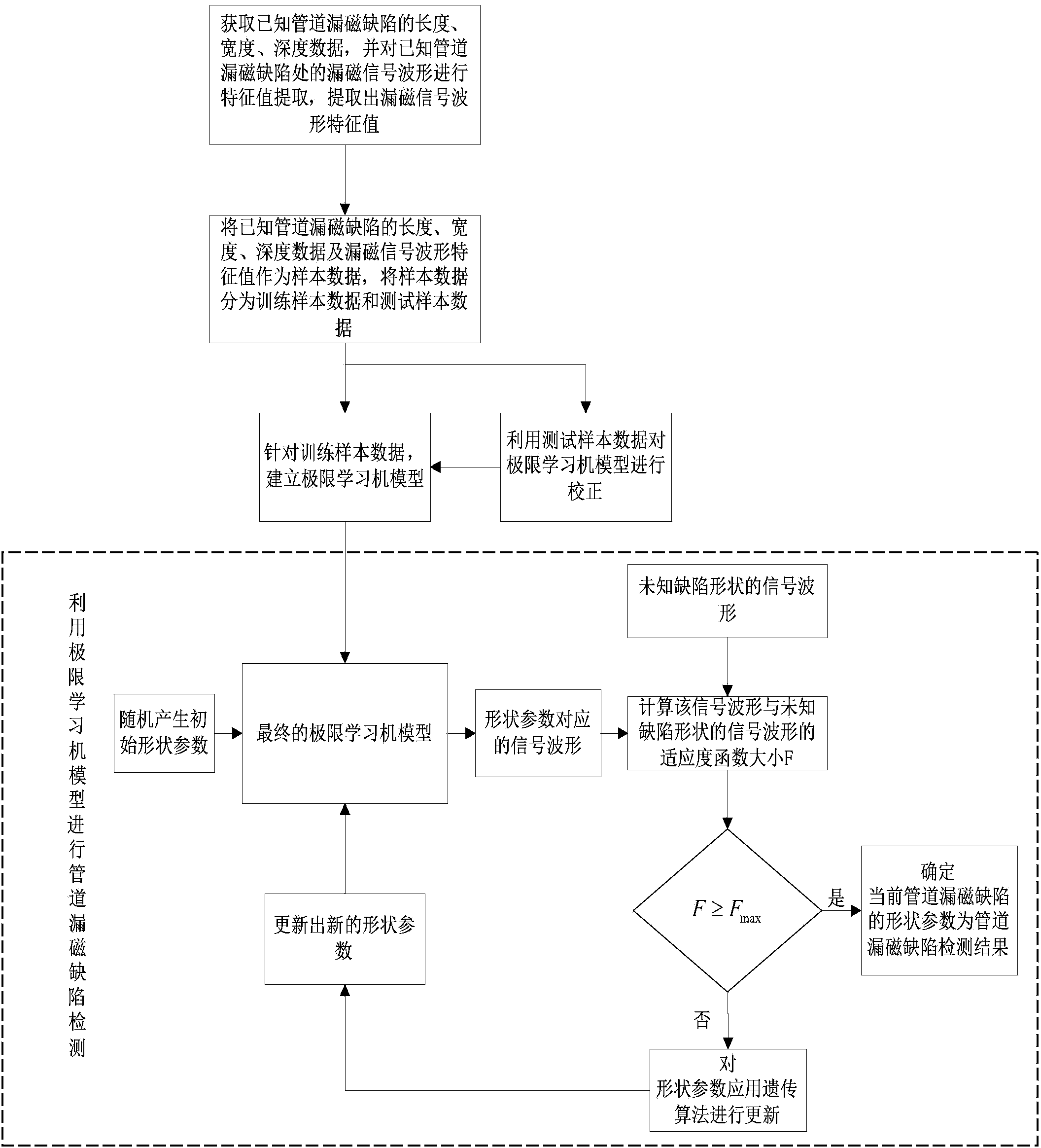

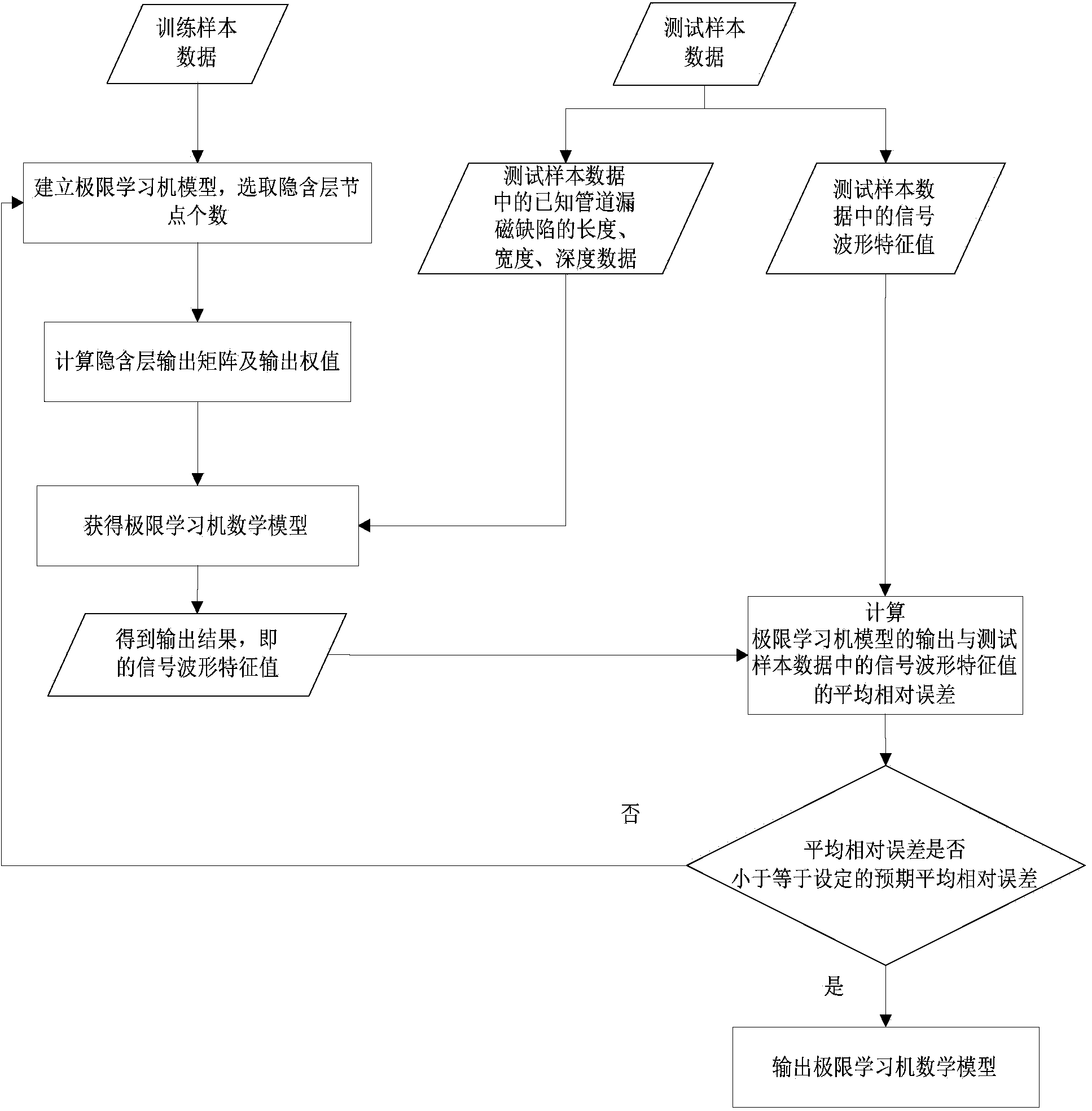

[0023] A pipeline magnetic flux leakage defect detection method based on extreme learning machine, such as figure 1 shown, including the following steps:

[0024] Step 1: Obtain the shape parameters of the known pipeline magnetic flux leakage defect, including the length, width and depth data of the pipeline magnetic flux leakage defect, and extract the eigenvalues of the magnetic flux leakage signal waveform at the known pipeline magnetic flux leakage defect to extract the magnetic flux leakage Signal waveform eigenvalues.

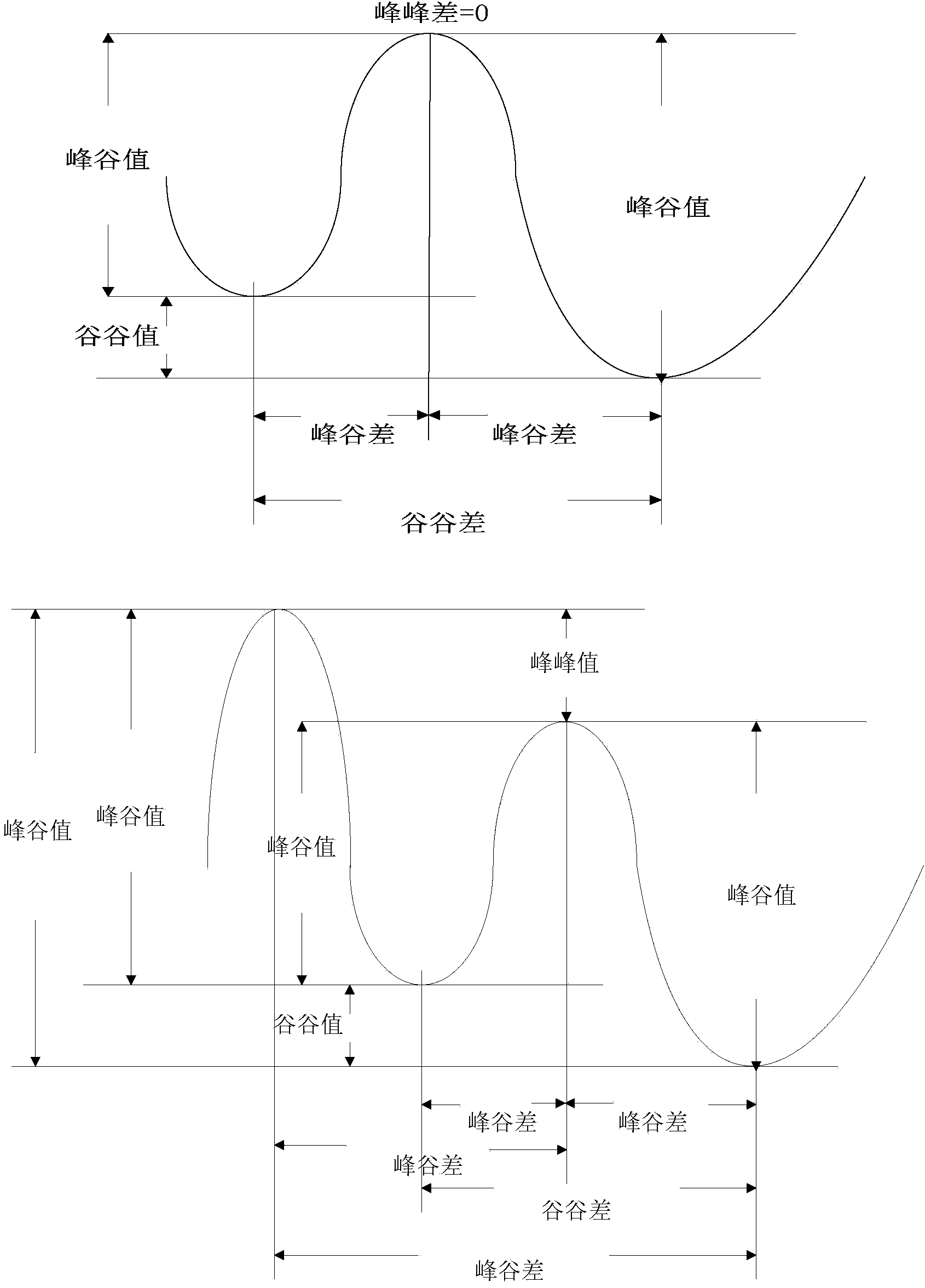

[0025] Step 1.1: Obtain the shape parameters of the known pipeline magnetic flux leakage defect, including the length, width and depth data of the pipeline magnetic flux leakage defect, obtain the defect signal waveform diagram of the known pipeline magnetic flux leakage defect, and obtain the horizontal and vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com