Method for assembling cable built-in fiber bragg grating strain transducer

A strain sensor and fiber grating technology, applied in the field of cable load-bearing structures, can solve problems such as cable damage, achieve the effect of ensuring survival rate, ensuring reliability and long-term stability, and solving process difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

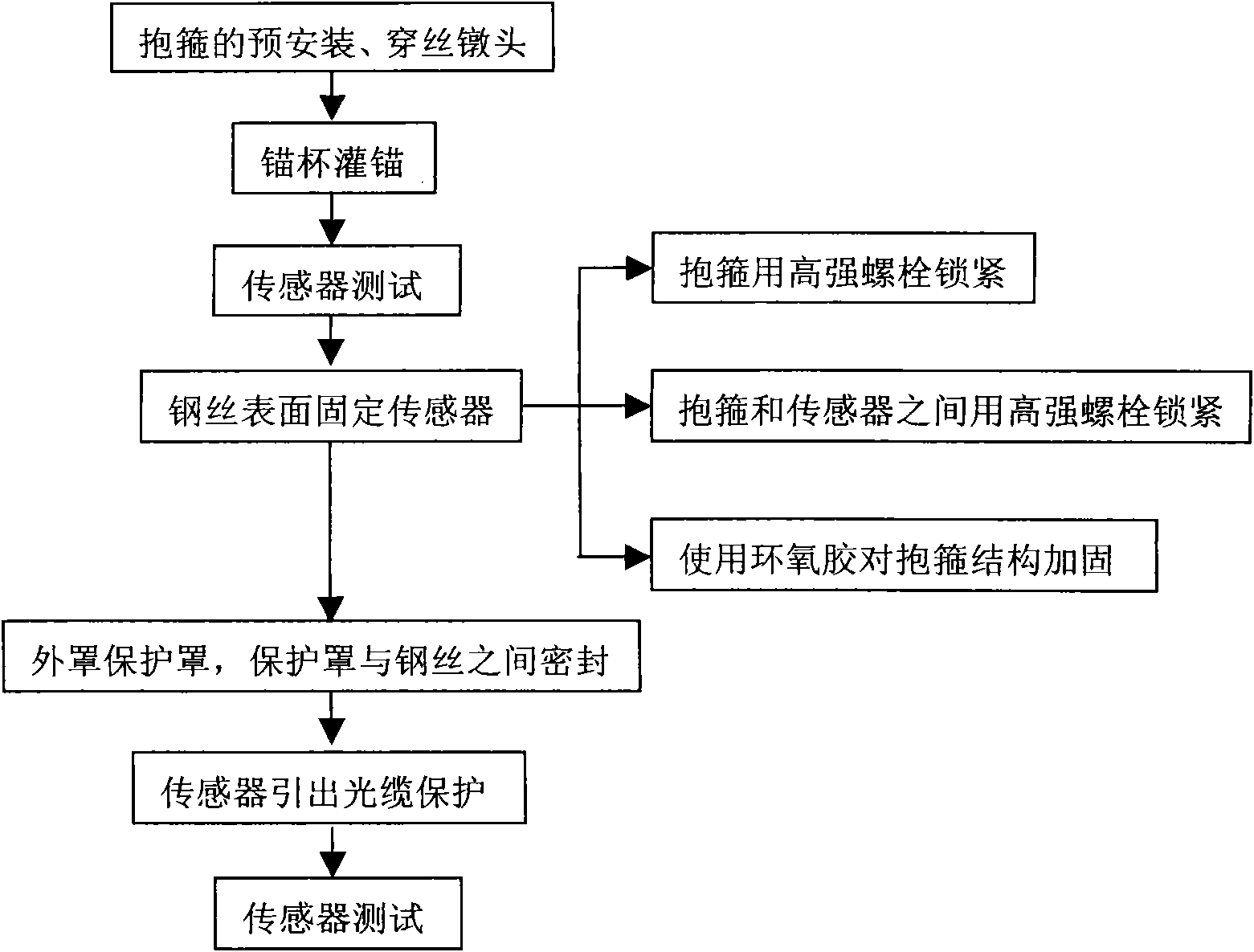

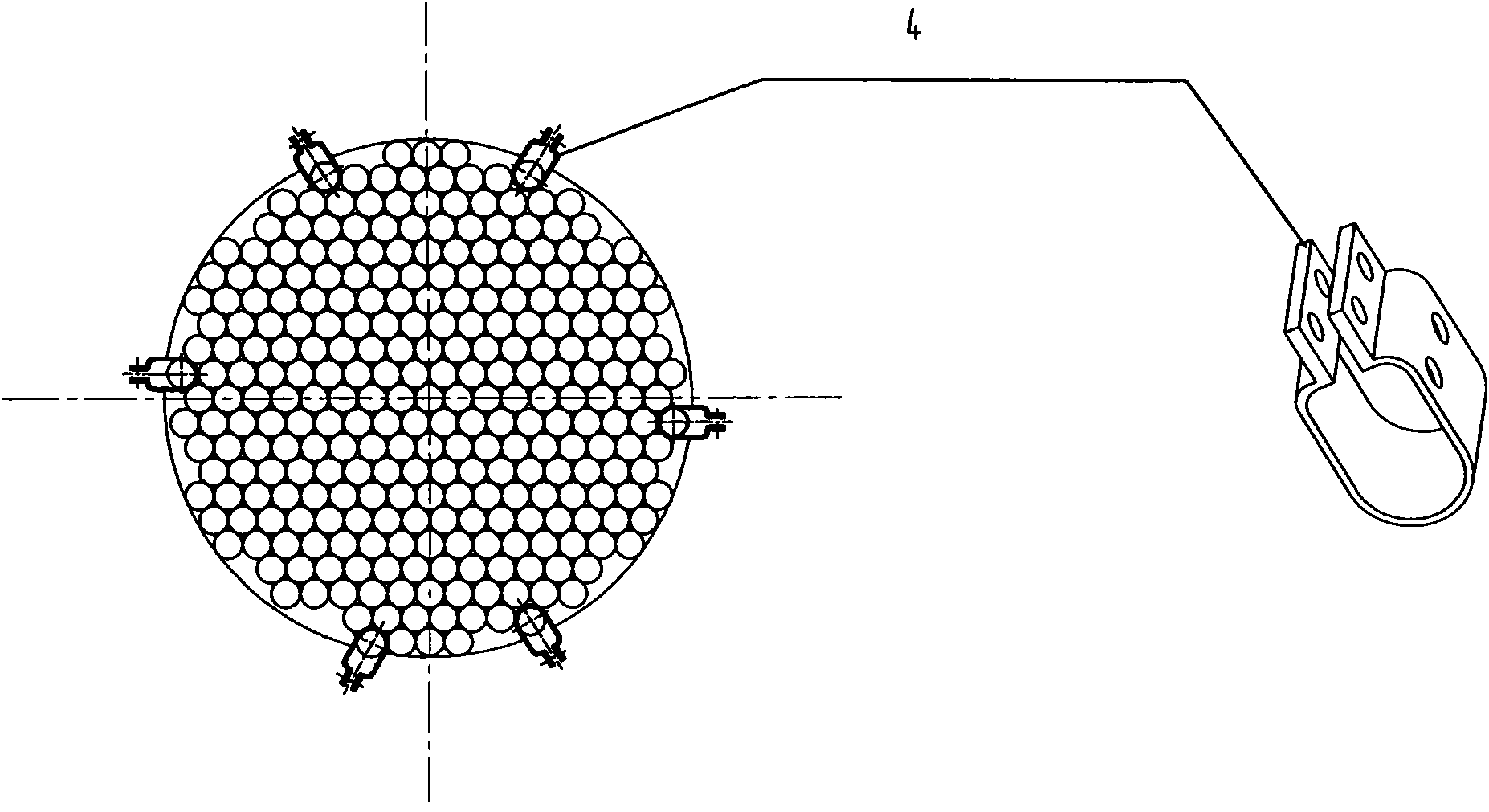

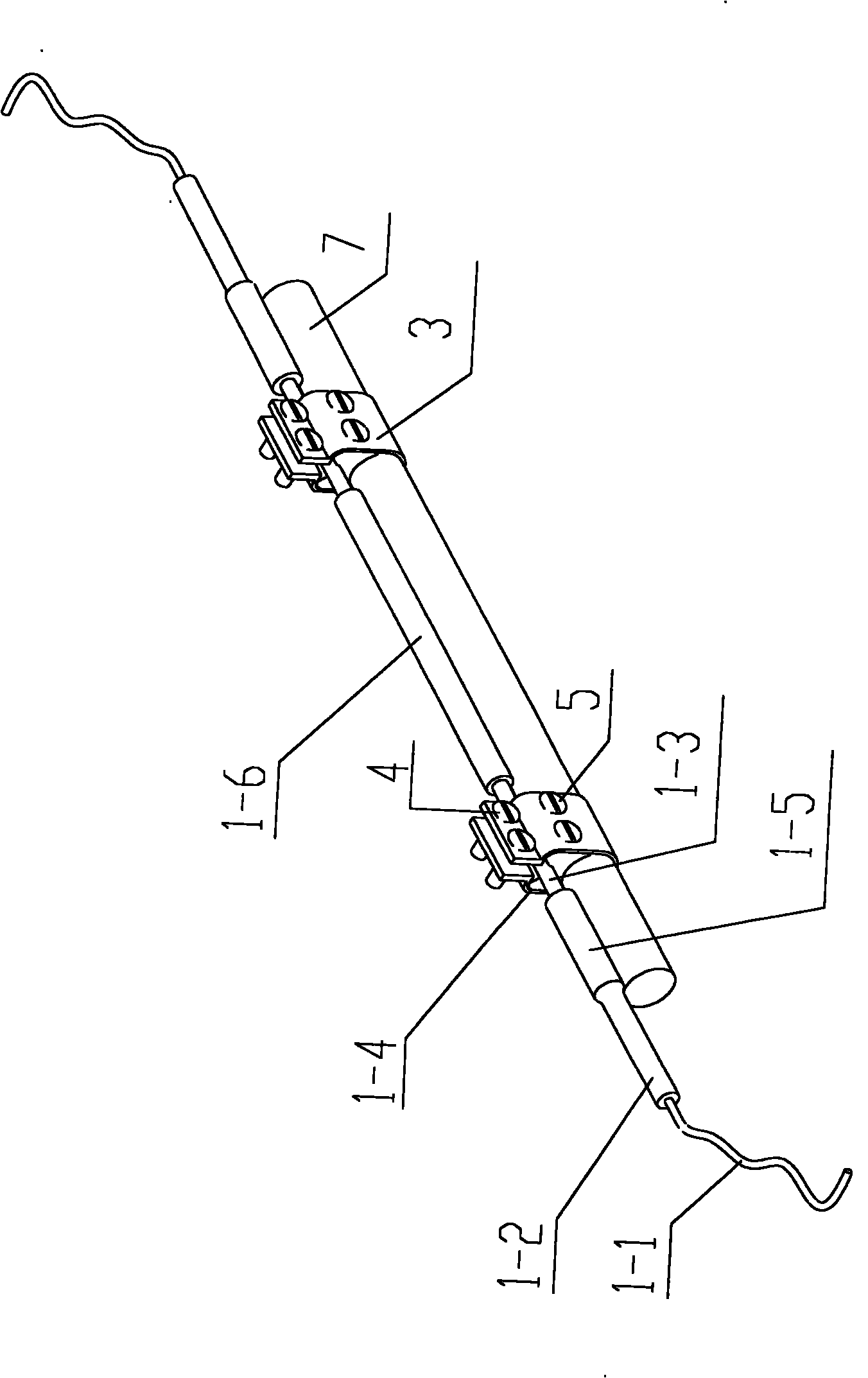

[0029] The installation process of the fiber grating strain sensor 1 in the cable is as follows: figure 1 shown. Before the wire threading and heading process of the cable, the hoop 3 is threaded on the peripheral steel wire 7 of the cable connecting cylinder where the fiber grating strain sensor 1 is to be installed, and two steel wires are installed on each steel wire. The pre-installation of the hoop 3 is completed. Such as figure 2 shown. After the cable filling and anchoring process is completed, the fiber grating strain sensor 1 is connected to a special instrument for testing to ensure that the sensor is intact. In the area of the cable connecting cylinder 6, after cleaning the surface of the peripheral steel wire 7 of the cable connecting cylinder where the optical fiber grating strain sensor 1 is to be arranged, fix the optical fiber grating strain sensor 1 to the surface of the peripheral steel wire 7 of the cable connecting cylinder with a hoop 3 , the hoop 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com