Fiber bragg grating intelligent steel strand and manufacturing method thereof

A smart steel strand and fiber grating technology, applied in the field of monitoring, can solve problems such as poor shear resistance and bending resistance, and insufficient monitoring range of fiber grating sensors, so as to improve accuracy and persuasiveness, improve deployment survival rate and The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present invention applies technical means to solve technical problems and achieve technical effects.

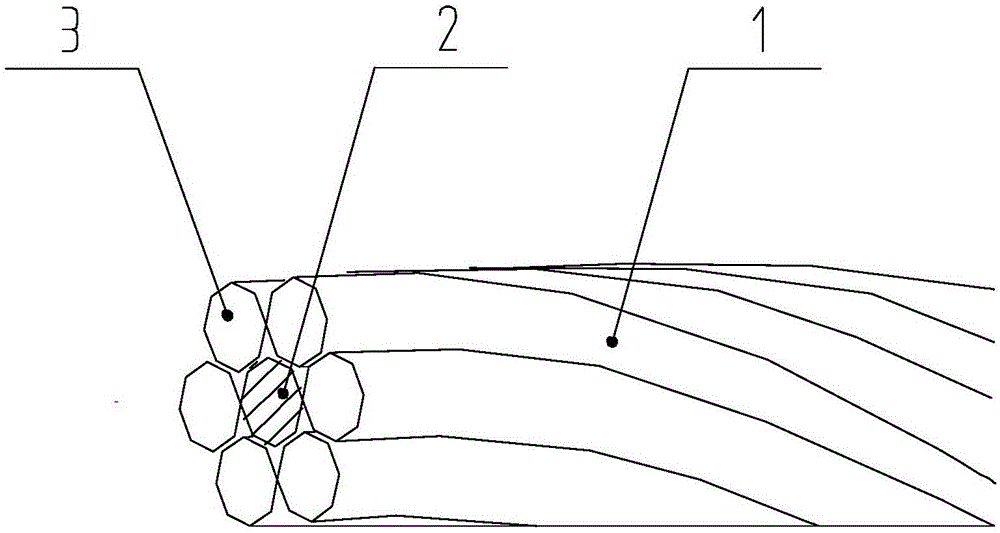

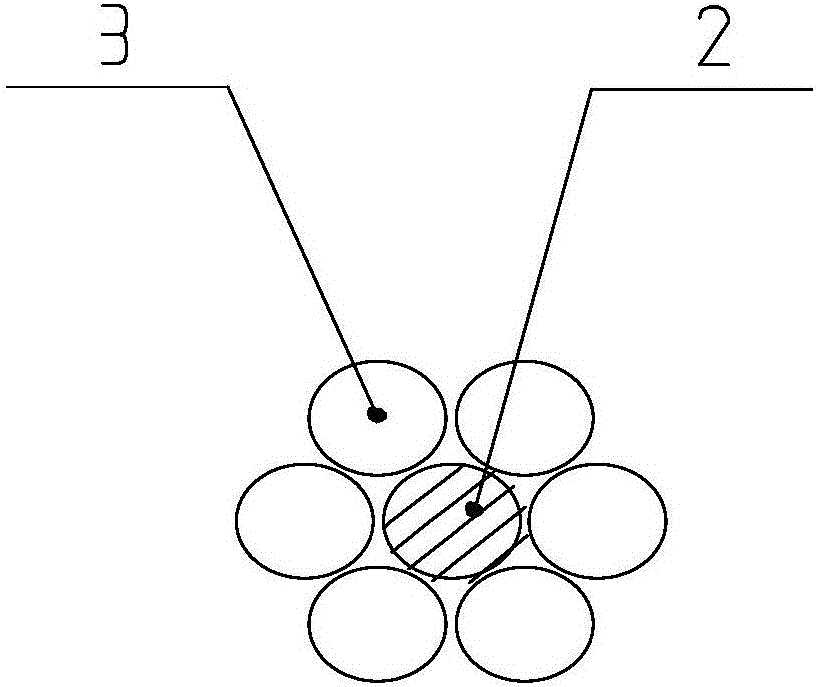

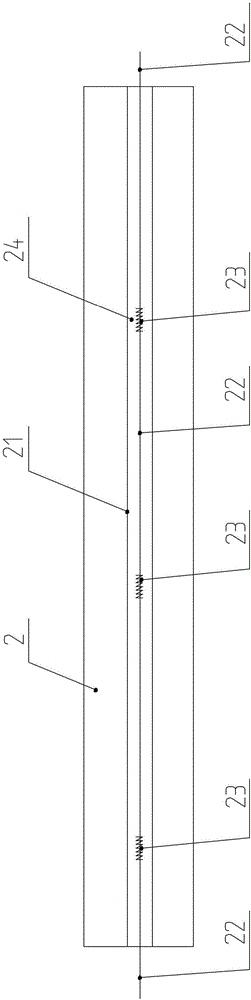

[0029] like Figure 1 to Figure 4 As shown, the fiber grating smart steel strand 1 of the embodiment of the present invention includes a center wire 2, and an edge wire 3 twisted with the center wire 2; the center wire 2 is provided with at least one groove 21, and the groove 21 is placed with The optical fiber 22, at least one grating 23 is engraved on the optical fiber 22.

[0030] The grooves 21 are longitudinal grooves, and the number of the grooves 21 is 1 to 6. The groove 21 is 0.1-0.8 mm deep and 0.1-1.5 mm wide, and the optical fiber 22 is pasted in the groove 21 by an adhesive 24 .

[0031] The embodiment of the present invention also provides a method for manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com