Nondestructive testing of a carrier element of an elevator installation

a carrier element and elevator technology, applied in the direction of instruments, elevators, optical radiation measurement, etc., can solve the problems of a simple visual inspection by a servicing engineer, a potential safety risk, and the inability to test the carrier element. , to achieve the effect of simple and cost-effective design of the test devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

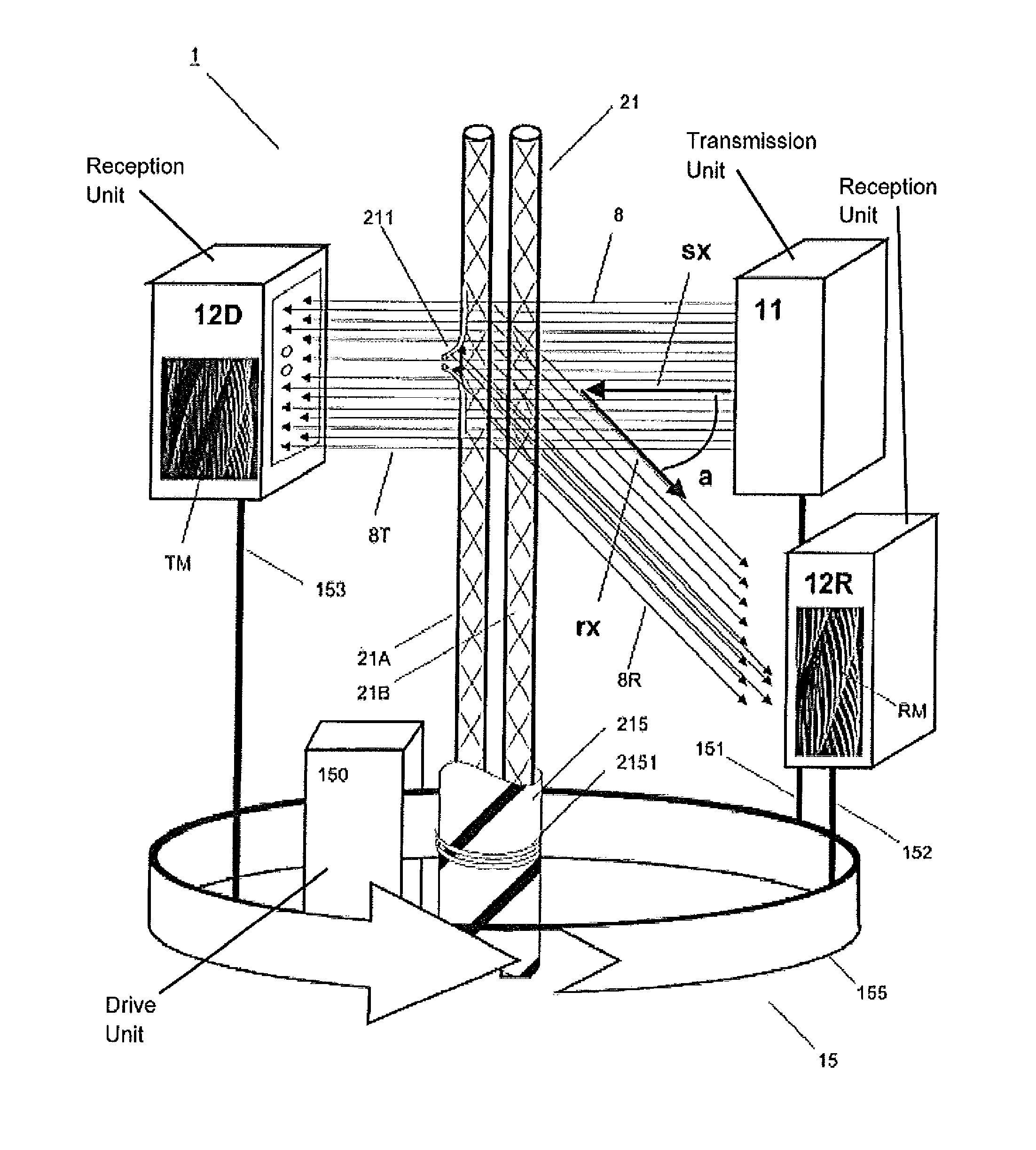

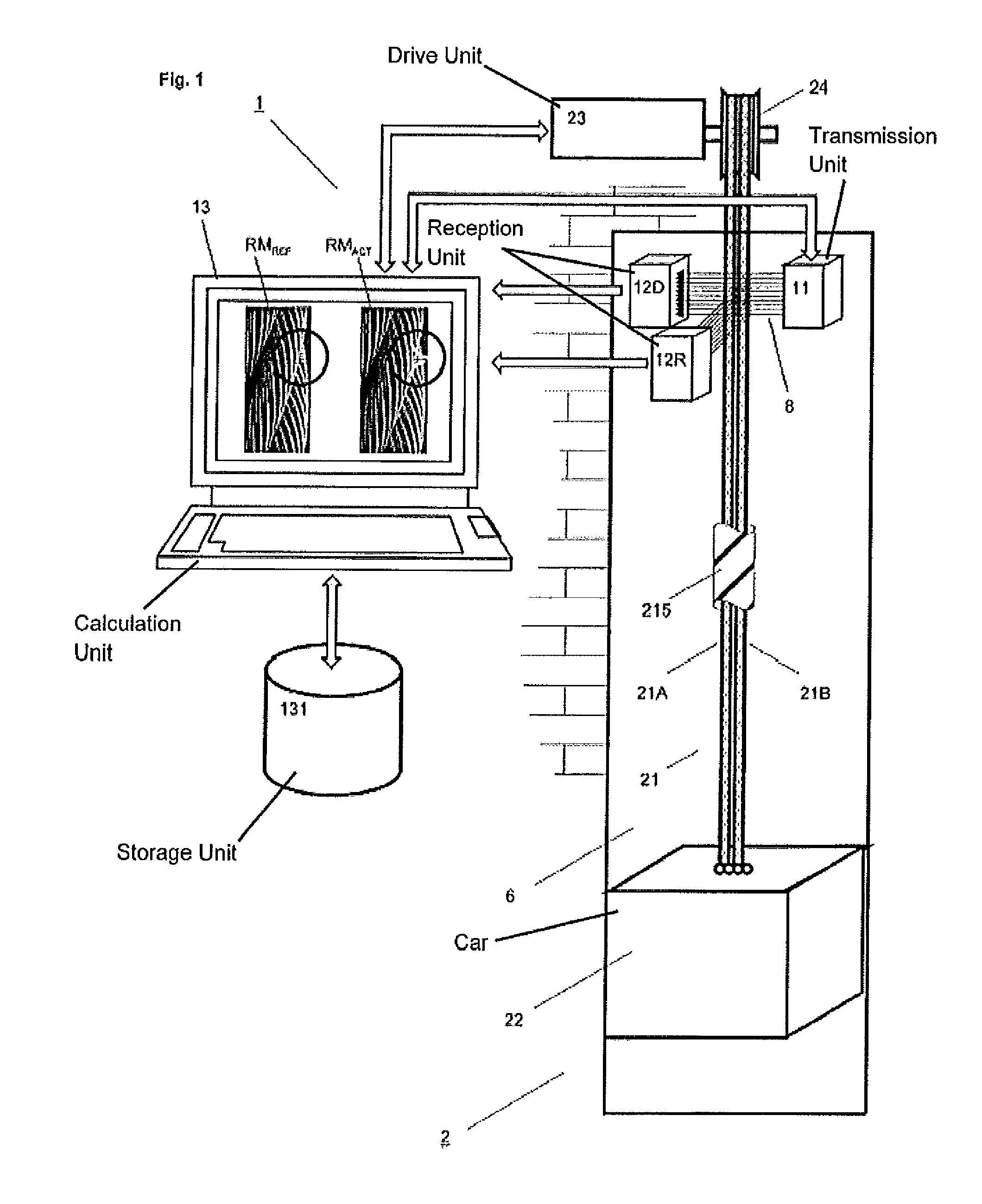

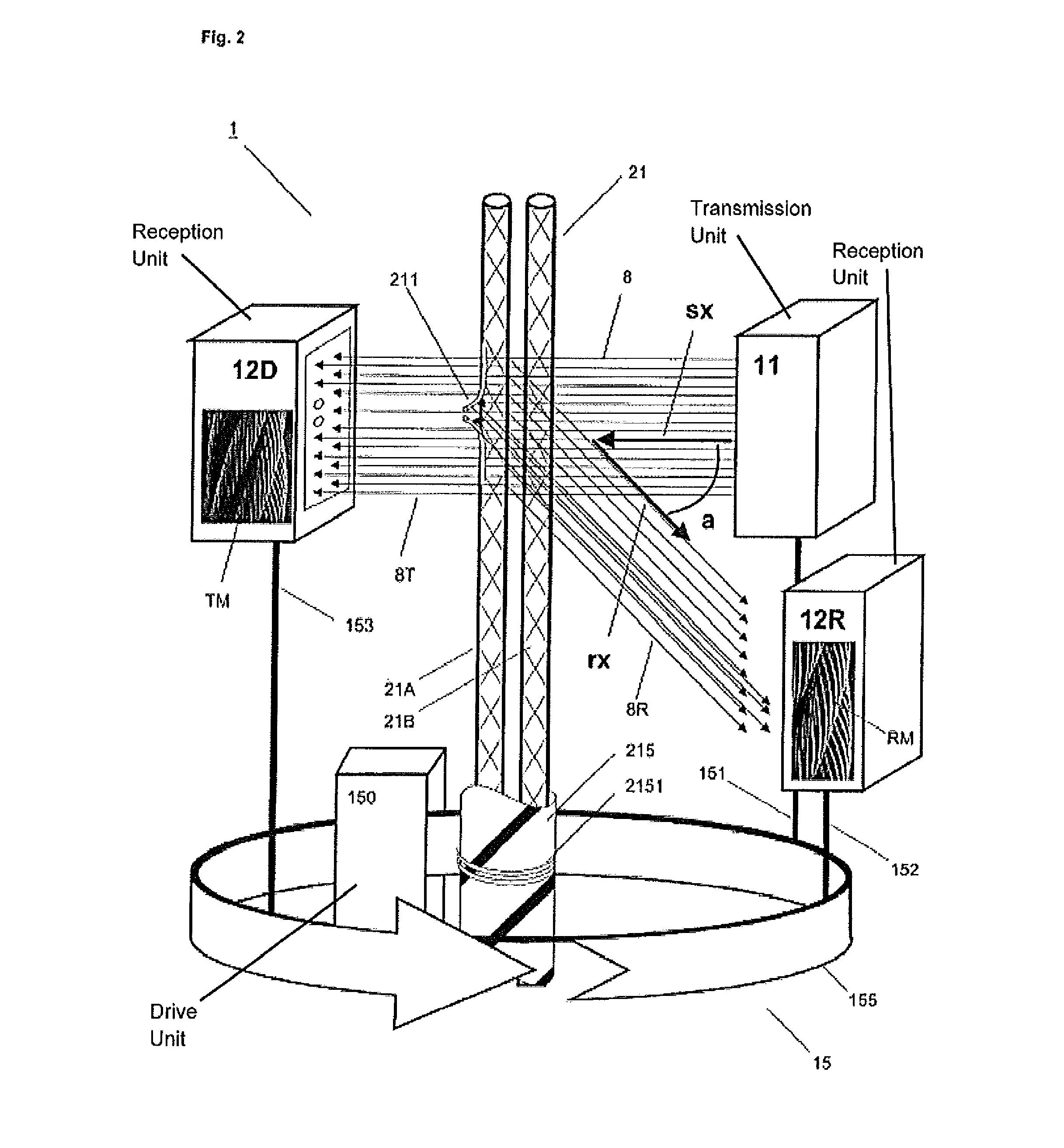

[0050]FIG. 1 shows a schematic illustration of an exemplary embodiment of an elevator installation 2, which has an elevator car 22 which can be displaced vertically in an elevator shaft 6 and is connected to a drive unit 23 via carrier elements 21 and a drive pulley 24. Further components of the elevator installation 2 (e.g. counterweight and safety apparatuses) or details in respect of the suspension of the elevator car 22 (e.g. 1:1, 2:1, etc. suspension) are not shown in FIG. 1 for reasons of clarity. However, it is understood that the exemplary embodiments described here can be used independently of these components or details, mentioned in an exemplary fashion, in the elevator installation 2.

[0051]The elevator installation 2 is furthermore provided with a test device 1 by means of which a carrier element 21 can be tested. In the illustrated exemplary embodiment, the carrier element 21 comprises a sheath 215 made of plastic in which, for example, two wire ropes 21A, 21B are integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com