Optical fiber strain and temperature simultaneous calibration device and method based on Brillouin scattering

A technology of Brillouin scattering and optical fiber strain, which is applied to measuring devices and instruments, can solve problems such as inconsistent ambient temperature, uneven strain application, and large calibration errors, so as to ensure consistency, improve calibration efficiency, and reduce calibration errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

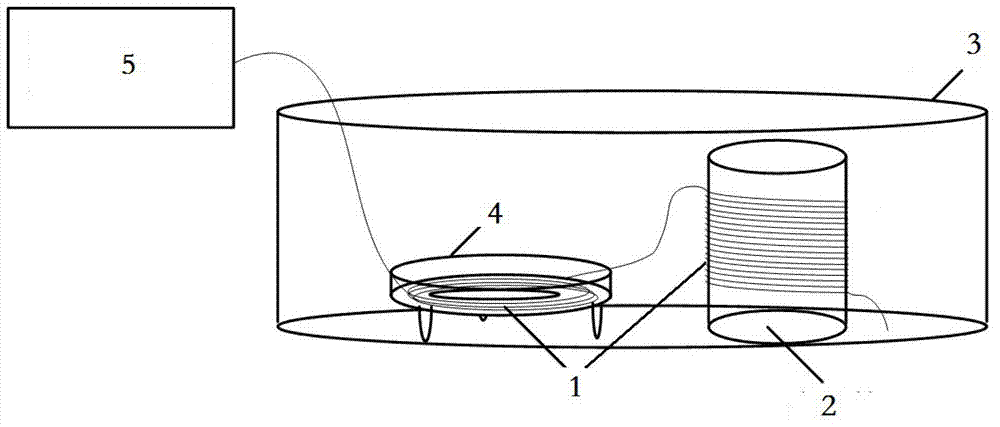

[0039] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

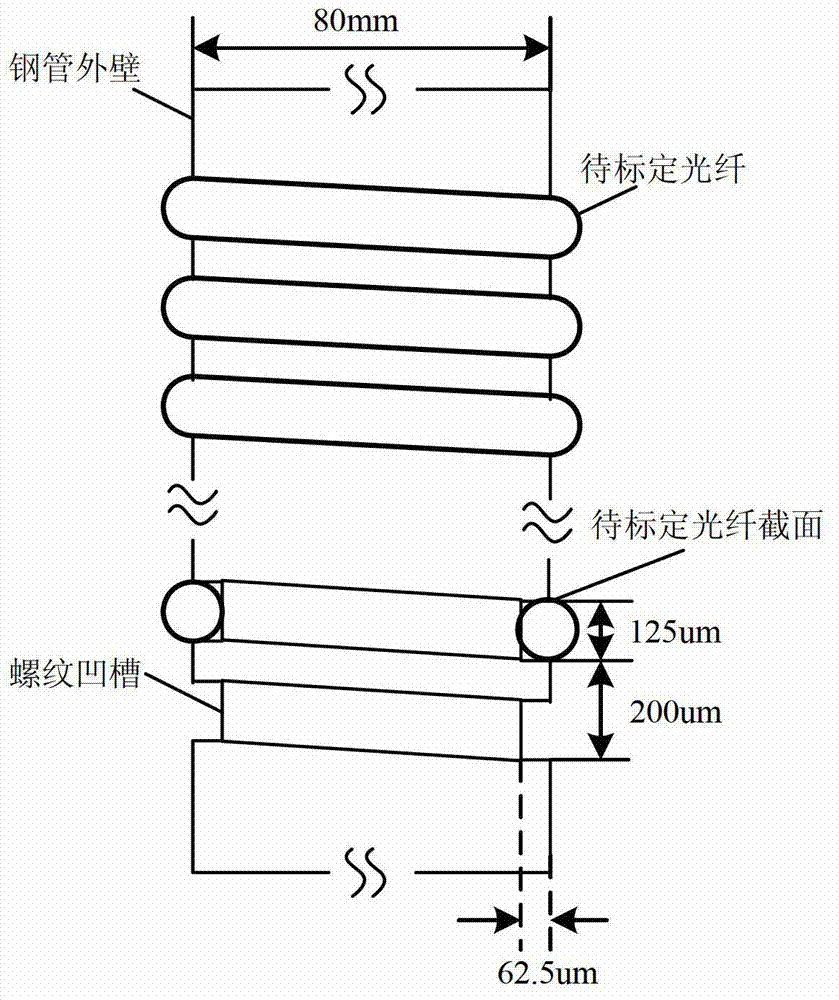

[0040] 1. Select the stainless steel pipe with the grade of 1Cr18Ni9, whose linear expansion coefficient is 15.5um / m*k (in the range of 20~100℃), and determine the outer diameter of the metal pipe to be 80mm and the thickness of the pipe wall to be 4mm. Evenly carve threads with a groove width of 125um, a groove depth of 62.5um, and a pitch of 200um on the outer wall, such as figure 1 shown.

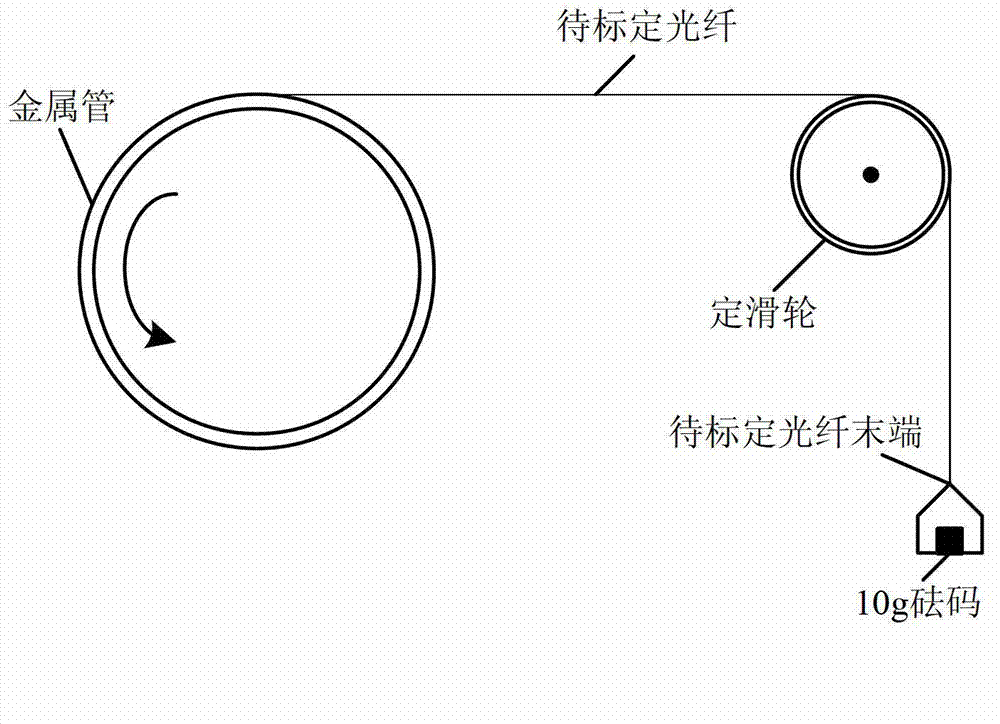

[0041] 2. Use waterproof glue to fix the optical fiber to be calibrated at a distance of 2.5m from the end on the outer wall of the metal tube. The fixing position should be on the groove extension line of the thread to ensure uniform force. From the fixed position, wrap 2m of the optical fiber to be calibrated along the thread groove on the metal tube wall with a constant tension, and fix the end of the fiber to be calibrated wound on the metal tube on the metal tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com