Universal waterproof coating

A kind of waterproof coating, general-purpose technology, applied in the direction of coating, etc., can solve the problems of poor performance of cement-based waterproof coating, low raw material cost, etc., and achieve the effect of improving water resistance and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] General-purpose waterproof paint, its weight portion is composed of 66% powder and 34% liquid material, wherein,

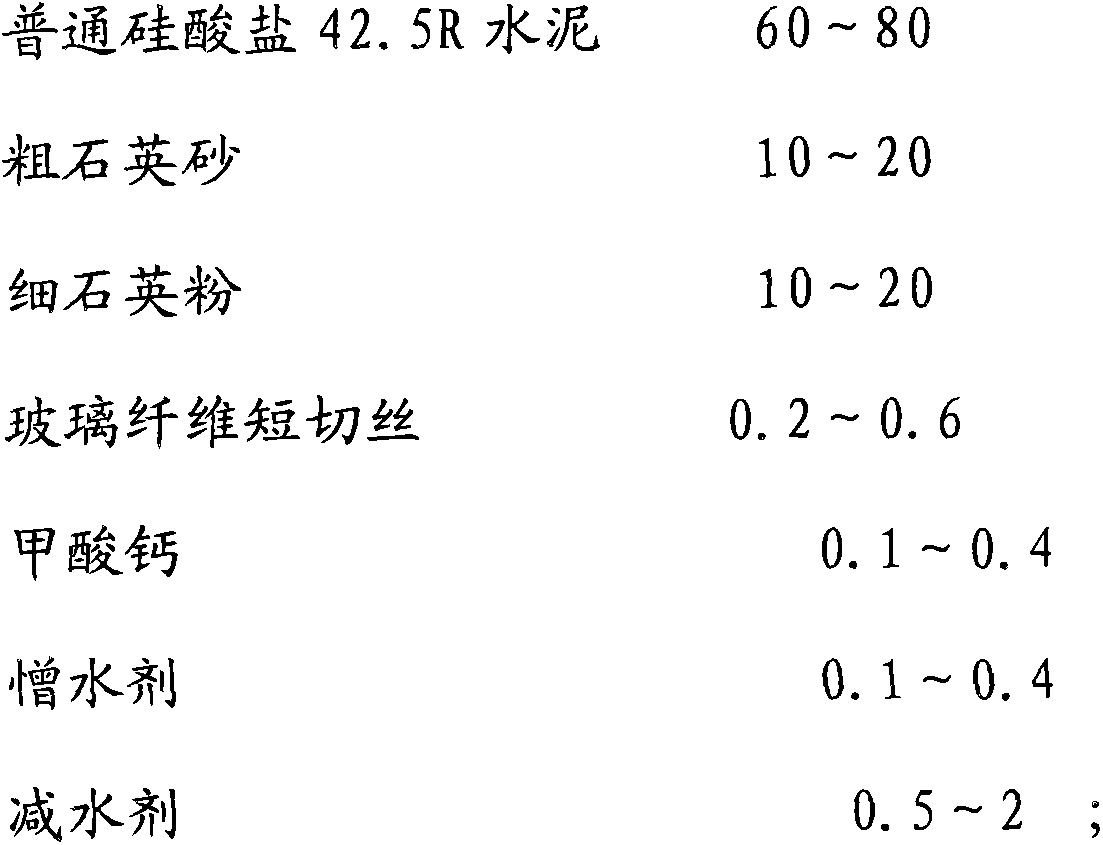

[0020] The powder consists of components in the following weight ratios:

[0021]

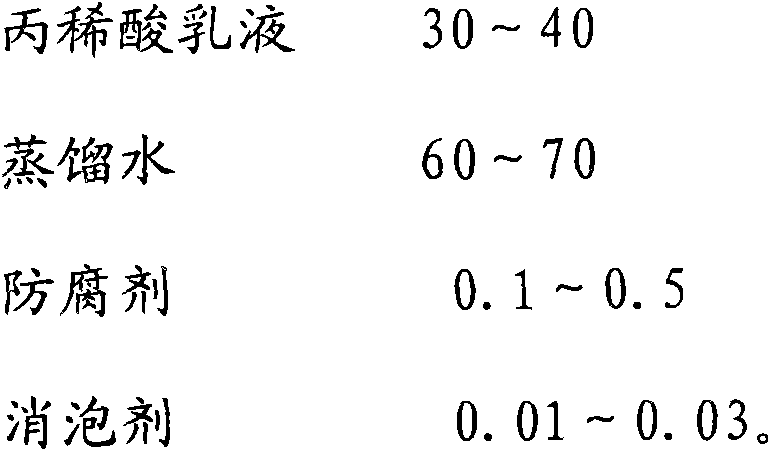

[0022] The liquid feed consists of components in the following weight ratios:

[0023]

[0024] The length of the glass fiber chopped strands is 2.5mm.

[0025] The particle size of the coarse quartz sand particles is 130 mesh.

[0026] The particle size of the fine quartz powder is 250 mesh.

[0027] The technical indicators of this embodiment are shown in Table 1.

[0028] The technical index of table 1 embodiment coating

[0029] Test items

[0030] It can be seen that the coating has good water resistance, weather resistance, aging resistance, and the same life as concrete. The product can penetrate into the capillary pores of the substrate, block the pores, and prevent leakage. At the same time, it has strong adhesion and can firmly adhere to the su...

Embodiment 2

[0032] General-purpose waterproof paint, its weight portion is composed of 60% powder and 40% liquid material, wherein,

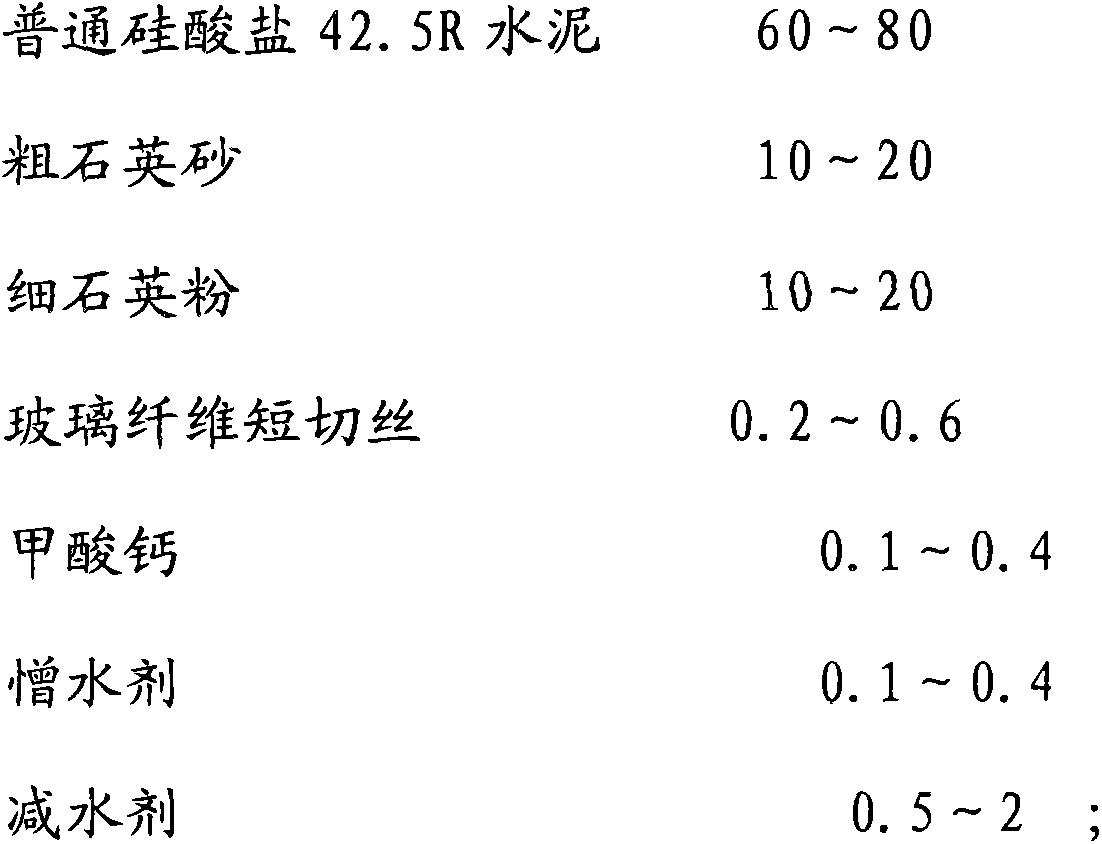

[0033] The powder consists of components in the following weight ratios:

[0034]

[0035] The liquid feed consists of components in the following weight ratios:

[0036]

[0037]

[0038] The length of the glass fiber chopped strands is 3mm.

[0039] The particle size of the coarse quartz sand particles is 150 mesh.

[0040] The particle size of the fine quartz powder is 300 mesh.

Embodiment 3

[0042] General-purpose waterproof coating, its weight part is composed of 70% powder and 30% liquid material, wherein,

[0043] The powder consists of components in the following weight ratios:

[0044]

[0045] The liquid feed consists of components in the following weight ratios:

[0046]

[0047] The length of the glass fiber chopped strands is 2mm.

[0048] The particle size of the coarse quartz sand particles is 120 mesh.

[0049] The particle size of the fine quartz powder is 200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com