High-strength integral composite material anchor shaft

A composite material, one-piece technology, applied in the field of high-strength one-piece composite material bolts, can solve problems such as poor bolt strength, nut cracking, shear fracture at thread joints, etc., to achieve safe and reliable cost, improve strength, The effect of high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

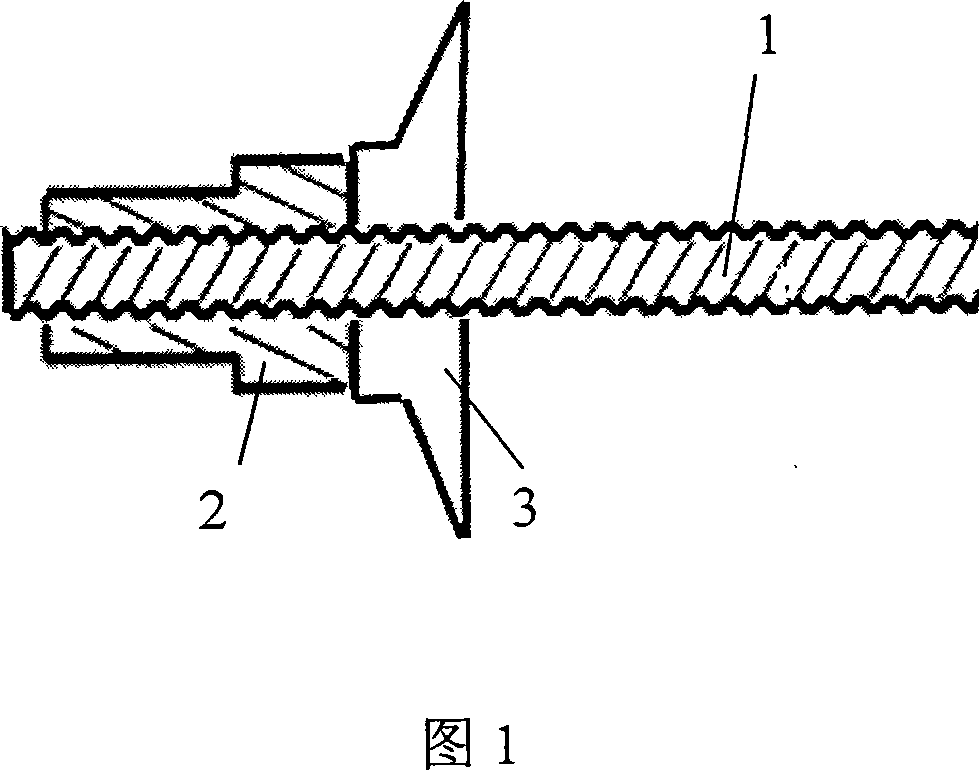

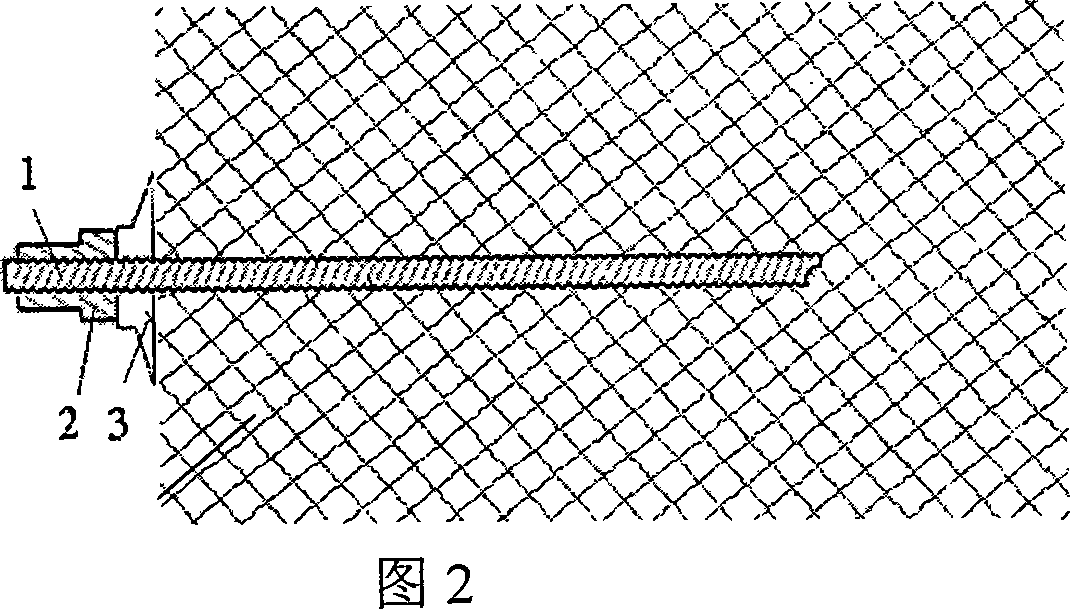

Embodiment 1

[0013] The high-strength integrated composite material anchor rod is composed of a threaded composite material rod body 1, a nut 2 and a tray 3, and the nut 2 is directly molded on the end of the rod body 1; the composite material constituting the nut is in the following weight percentage Composition of raw materials: short glass fiber 35%, 191# or 196# resin 30%, copper peroxide (as a curing agent) 4%, cobalt styrene isozincate (as an accelerator) 3%, calcium carbonate (as a filler ) 20%, aluminum hydroxide (as a flame retardant) 6%, antistatic agent 2%. Wherein, cobalt isozincate styrene is a solution of cobalt isozincate in styrene in any proportion, for example, 50% cobalt isozincate in styrene is used.

[0014] In order to further improve the strength of the anchor rod, the composite material constituting the rod body is made of the following raw materials in weight percentage: 50% of continuous glass fiber bundles, 10% of short glass fibers, 25% of 191# or 196# resin, co...

Embodiment 2

[0017] The high-strength integrated composite material anchor rod is composed of a threaded composite material rod body 1, a nut 2 and a tray 3, and the nut 2 is directly molded on the end of the rod body 1; the composite material constituting the nut is in the following weight percentage Composition of raw materials: short glass fiber 42%, 191# or 196# resin 30%, methyl ethyl copper peroxide (as curing agent) 2%, cobalt styrene isozincate (as accelerator) 3%, calcium carbonate (as filler ) 15%, aluminum hydroxide (as a flame retardant) 6%, antistatic agent 2%. Wherein, cobalt isozincate styrene is a solution of cobalt isozincate in styrene in any proportion, for example, 30% cobalt isozincate in styrene is used.

[0018] In order to further improve the strength of the anchor rod, the composite material constituting the rod body is made of the following raw materials in weight percentage: 53% of continuous glass fiber bundles, 5% of short glass fibers, 30% of 191# or 196# resi...

Embodiment 3

[0021] The high-strength integrated composite material anchor rod is composed of a threaded composite material rod body 1, a nut 2 and a tray 3, and the nut 2 is directly molded on the end of the rod body 1; the composite material constituting the nut is in the following weight percentage Composition of raw materials: short glass fiber 35%, 191# or 196# resin 35%, copper peroxide (as curing agent) 2%, cobalt styrene isozincate (as accelerator) 3%, calcium carbonate (as filler ) 16%, aluminum hydroxide (as a flame retardant) 7%, antistatic agent 2%. Wherein, cobalt isozincate styrene is a solution of cobalt isozincate in styrene in any proportion, for example, 60% cobalt isozincate in styrene is used.

[0022] In order to further improve the strength of the anchor rod, the composite material constituting the rod body is made of the following raw materials in weight percentage: 57% of continuous glass fiber bundles, 8% of short glass fibers, 27% of 191# or 196# resin, copper per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com