Nylon material with star branched structure and preparation method thereof

A technology of branched structure and nylon composite materials, applied in mechanical equipment, charging systems, engine components, etc., can solve the problem of high quality and high stability of auto parts, affect economic practicability and mass supply promotion, and increase material costs and other problems, to achieve excellent surface finish, improve fuel utilization, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

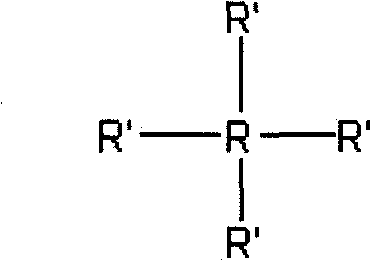

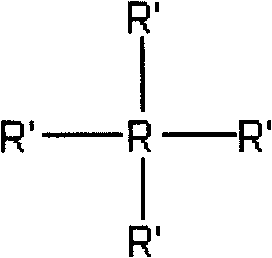

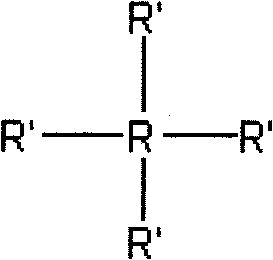

[0037] Table 1 shows the components and the mass content of each component of the nylon composite material with star branched structure in Examples 1-9. Wherein, the nylon is selected from one or several compositions of PA6, PA66, PA612, PA11, PA12, PA1010, PPA, PA46, PA6T, PA9T and PA6 / 66 polymers; the short glass fiber is The alkali-free short glass fiber that is processed through silane coupling agent; The molecular formula of described star branching agent is:

[0038]

[0039] R is an aromatic segment, an aliphatic segment or an epoxy segment, R' is an amino, carboxyl or hydroxyl functional group that can react with nylon end groups, and the number of R' functional groups is ≥3.

[0040] Preferably, the star branching agent is tricarboxybenzenesulfonic acid, triaminotriphenylmethane or trihyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com