Colorful photoaging-resistant glass fiber reinforced polyamide and preparation method thereof

A light-resistant and aging-resistant polyamide technology, which is applied in the field of colored light-resistant aging glass fiber reinforced polyamide and its preparation, can solve the problems such as the influence of material color and color difference, and achieve the effect of solving product discoloration, reducing color difference change, and solving product performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

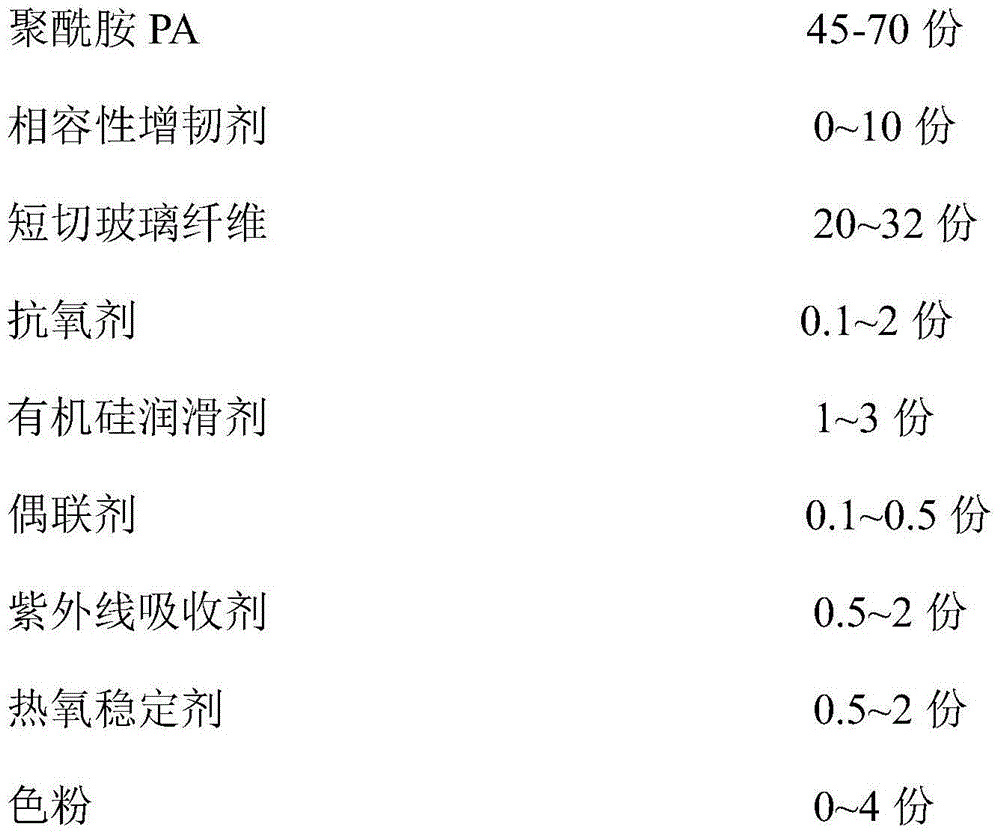

Method used

Image

Examples

Embodiment 1

[0023] The colored light aging resistant glass fiber reinforced polyamide material of the present embodiment is made up of the following components by weight: 64.4 parts of polyamide PA6, 1 part of maleic anhydride grafted POE, 2 parts of maleic anhydride grafted EPDM, 20 parts of short Cut glass fiber (length: 3-4.5mm; diameter: 8-15μm), 0.3 parts of hindered phenolic antioxidant, 0.1 part of phosphite synergistic antioxidant, 1 part of silicone lubricant, 0.1 part of 3- Glycidyl etheroxypropyl trimethoxysilane, 0.6 parts of UV absorber, 0.5 parts of organic amine phenol thermal oxygen stabilizer, 0.0052 parts of 10000 mesh ultrafine titanium dioxide, 0.0032 parts of azo condensation type Yellow3G yellow, 0.0041 parts of single Azo orange, 0.001 part silicone light diffusing agent.

[0024] The preparation method of the colored light aging resistant glass fiber reinforced polyamide material of the present embodiment comprises the following steps:

[0025] S1. Polyamide PA6, ...

Embodiment 2

[0029] This embodiment is roughly the same as Example 1, the difference mainly lies in the parts by weight of each component, specifically as follows: 62.4 parts of polyamide PA6, 2 parts of maleic anhydride grafted POE, 3 parts of maleic anhydride grafted EPDM, 30 parts of short Cut glass fiber (length: 3-4.5mm; diameter: 8-15μm), 0.4 parts of hindered phenolic antioxidant, 0.2 part of phosphite synergistic antioxidant, 0.8 part of silicone lubricant, 0.1 part of 3- Glycidyl etheroxypropyl trimethoxysilane, 0.6 parts of UV absorber, 0.5 parts of organic amine phenol thermal oxygen stabilizer, 0.0052 parts of 10000 mesh ultrafine titanium dioxide, 0.0032 parts of azo condensation type Yellow3G yellow, 0.0041 parts of single Azo orange, 0.001 part silicone light diffusing agent.

[0030] A colored light-resistant aging glass fiber reinforced polyamide material and a preparation method thereof, comprising the following steps:

[0031] S1. Polyamide PA6, maleic anhydride grafted...

Embodiment 3

[0035] This embodiment is roughly the same as Example 1, the difference mainly lies in the parts by weight of each component, specifically as follows: 55.4 parts of polyamide PA6, 1 part of maleic anhydride grafted POE, 1 part of maleic anhydride grafted EPDM, 40 parts of short Cut glass fiber (length: 3-4.5mm; diameter: 8-15μm), 0.3 hindered phenolic antioxidant, 0.1 phosphite synergistic antioxidant, 1 silicone lubricant, 0.1 3-shrink Glyceryl etheroxypropyl trimethoxysilane, 0.6 part of UV absorber, 0.5 part of organic amine phenol thermal oxygen stabilizer, 0.0052 part of 10000 mesh ultrafine titanium dioxide, 0.0032 part of azo condensation type Yellow3G yellow, 0.0041 part of monoeven Nitrogen orange, 0.001 part silicone light diffusing agent.

[0036] A colored light-resistant aging glass fiber reinforced polyamide material and a preparation method thereof, comprising the following steps:

[0037] S1. Polyamide PA6, maleic anhydride grafted POE, maleic acid grafted EPD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com