High-performance resin/ mica composite material and its production method

A composite material, high-performance technology, applied in the field of polymer materials, can solve the problems of rough surface of products, inconsistent transverse shrinkage rate, easy warping of products, etc., and achieve the effects of high production efficiency, good dimensional stability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Dry 30 parts of mica powder (phlogopite, 325 mesh) at 80-100°C for 2-5 hours, then add 0.3 parts of silane coupling agent KH-550 in proportion, and mix with a high-speed mixer carry out activation treatment;

[0023] (2) Combining the threaded block components of the twin-screw extruder, and adopting a three-stage kneading method to configure the threaded block, the kneading block adopts a positive and negative 45° angle kneading block and a 90° angle kneading block to match;

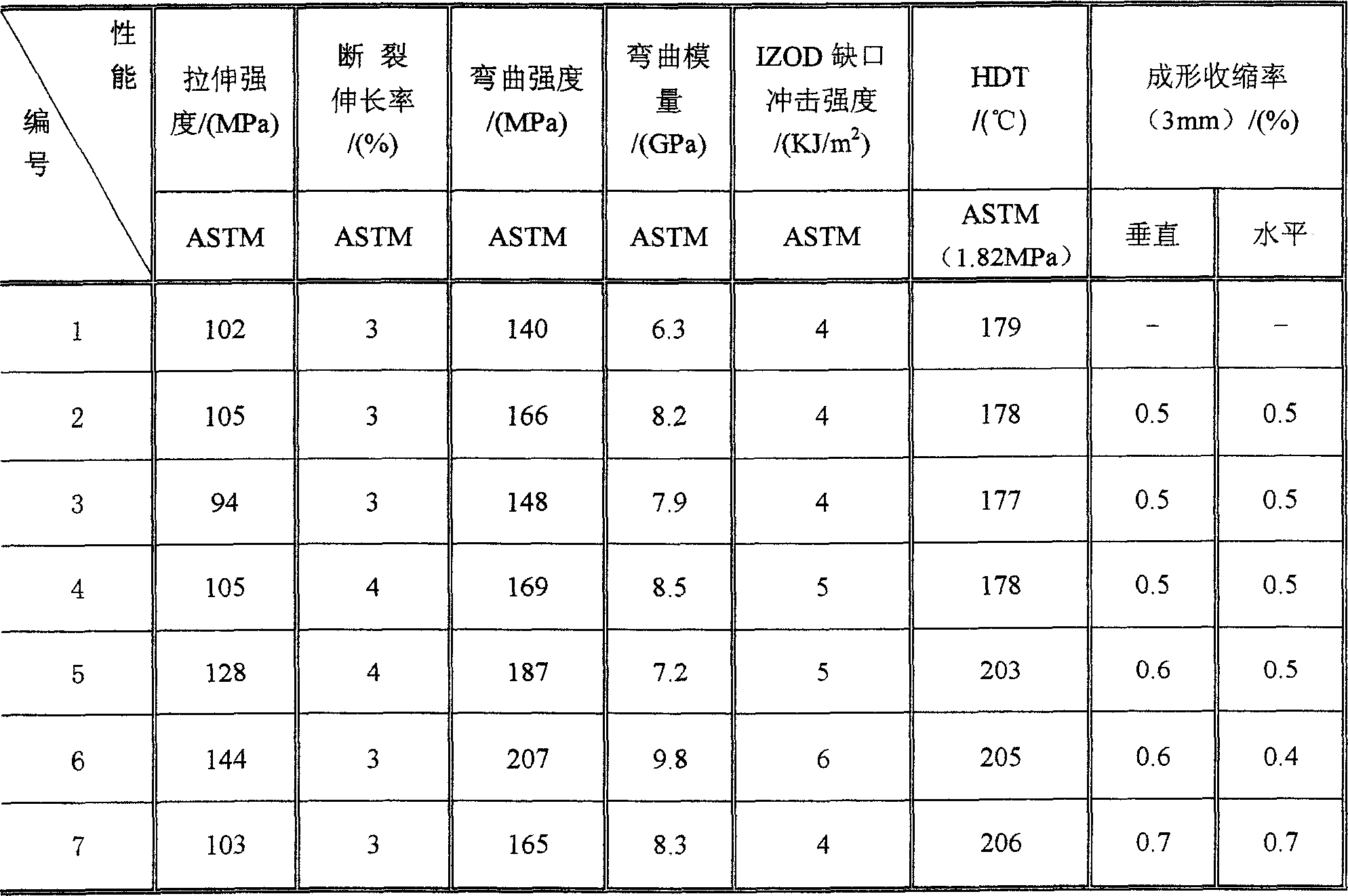

[0024] (3) 70 parts of nylon 6, 0.2 part of lubricant calcium stearate, 0.2 part of methyl silicone oil, 0.2 part of antioxidant 1010 and activated mica powder are mixed or transported to a twin-screw extruder respectively for extruding After granulation, the product is obtained after drying. Its performance is shown in Attachment 1 in 1 # shown.

Embodiment 2

[0026] The components of this embodiment are: 70 parts of nylon 6, 30 parts of mica, 0.3 part of silane coupling agent KH-550, and 0.2 part of lubricant methyl silicone oil; wherein the mica is muscovite with a mesh size of 500 mesh. All the other are the same as embodiment 1, its performance sees 2 in the attached table 1 # shown.

Embodiment 3

[0028] The composition components of this embodiment are: 70 parts of nylon 6, 30 parts of mica, 0.3 part of silane coupling agent KH-550, 0.3 part of antioxidant 1010, and 0.2 part of lubricant calcium stearate; wherein mica is phlogopite , the number of mesh is 1000 mesh. All the other are the same as embodiment 1, its performance sees 3 in the attached table 1 # shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com