Preparation method of powder metallurgy material for train brake pad

A technology of powder metallurgy and brake pads, which is applied in the field of preparation of powder metallurgy materials for train brake pads. It can solve the problems of low strength of polymer composite materials, inability to apply braking requirements, and ineffective braking, etc., to achieve excellent friction stability. and the effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

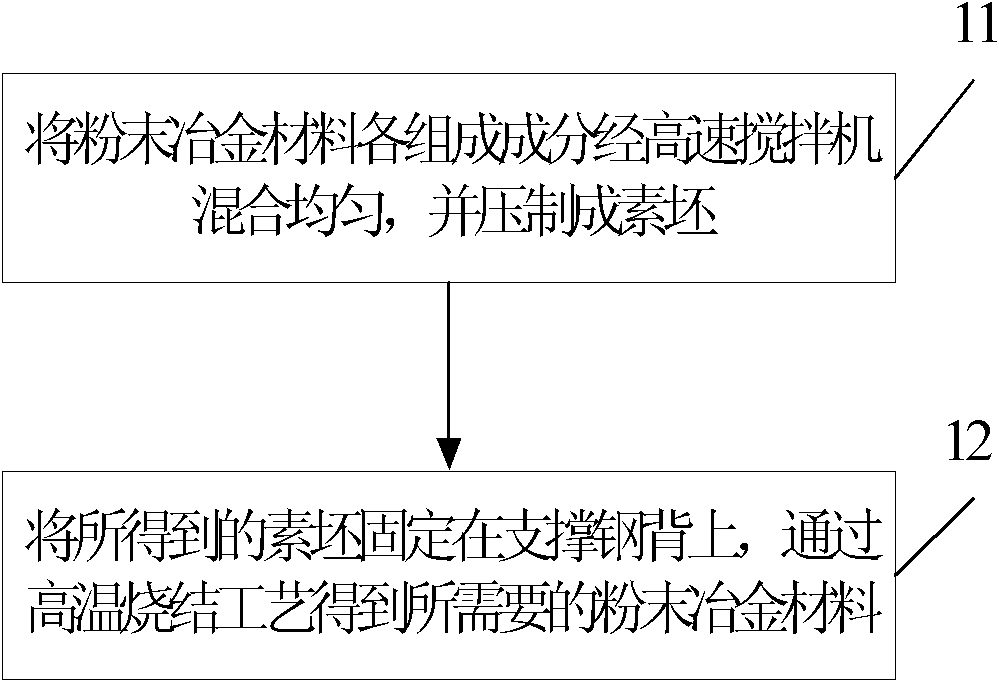

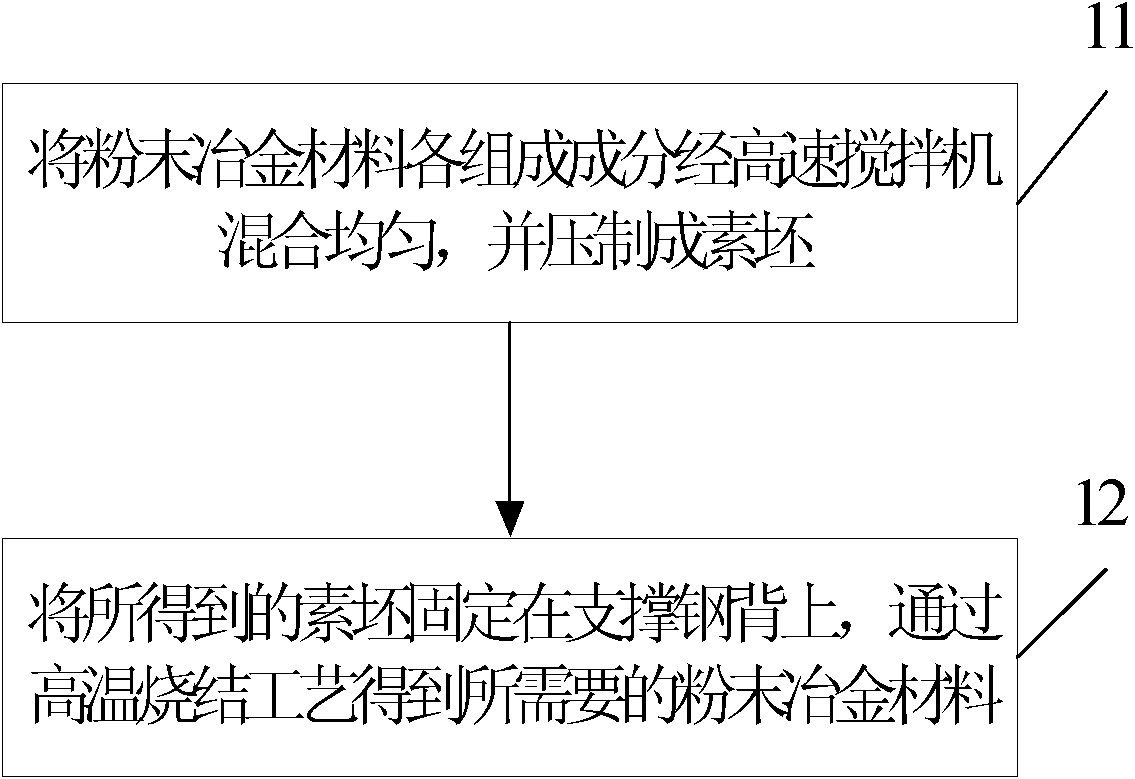

[0014] In order to better describe the embodiment of the present invention, the specific implementation manner of the present invention will be described in conjunction with the accompanying drawings, as follows figure 1 Shown is a schematic flow chart of the method for preparing powder metallurgy materials for train brake pads provided by the embodiment of the present invention, and the method includes:

[0015] Step 11: Mix the components of the powder metallurgy material evenly with a high-speed mixer, and press them into a green body.

[0016] In the specific implementation process, the components of the powder metallurgy material are divided by weight, which can include 40% copper powder, 24.8% iron powder, 10% manganese iron ore powder, 2% silicon dioxide, 5% molybdenum disulfide, oxide Aluminum 2%, boron nitride 1%, graphite 15%, polyacrylonitrile fiber 0.2%.

[0017] Specifically, the above process may be that the components are uniformly mixed by a high-speed mixer, ...

Embodiment 1

[0024] Prepare each component according to weight ratio: copper powder 40%, iron powder 24.8%, manganese iron ore powder 10%, silicon dioxide 2%, molybdenum disulfide 5%, aluminum oxide 2%, boron nitride 1%, graphite 15% %, polyacrylonitrile fiber 0.2%; mix the above powders evenly, press under 600MPa pressure to obtain compact; fix the compact on the supporting steel back, and sinter at 920°C, 2MPa pressure, hydrogen protection for 3 hours to obtain Powder metallurgy friction material. The powder metallurgy material prepared according to the above process has a hardness of 56HB and a compressive strength of 125MPa.

Embodiment 2

[0026] Prepare each component according to weight ratio: copper powder 43%, iron powder 12.6%, manganese iron ore powder 15%, silicon dioxide 4%, molybdenum disulfide 6%, aluminum oxide 3%, boron nitride 2%, graphite 16% %, polyacrylonitrile fiber 0.4%. Mix the above powders evenly, and press under 600MPa pressure to obtain a compact; fix the compact on a supporting steel back, and sinter at 900°C, 3MPa pressure, and hydrogen protection for 3 hours to obtain a powder metallurgy friction material. The powder metallurgy material prepared according to the above process has a hardness of 58HB and a compressive strength of 132MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com