Rail eddy current brake

A technology of eddy current brakes and rails, which is applied in the direction of brakes interacting with brake components and rails, railway braking systems, transportation and packaging, etc. Destructive effect, the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

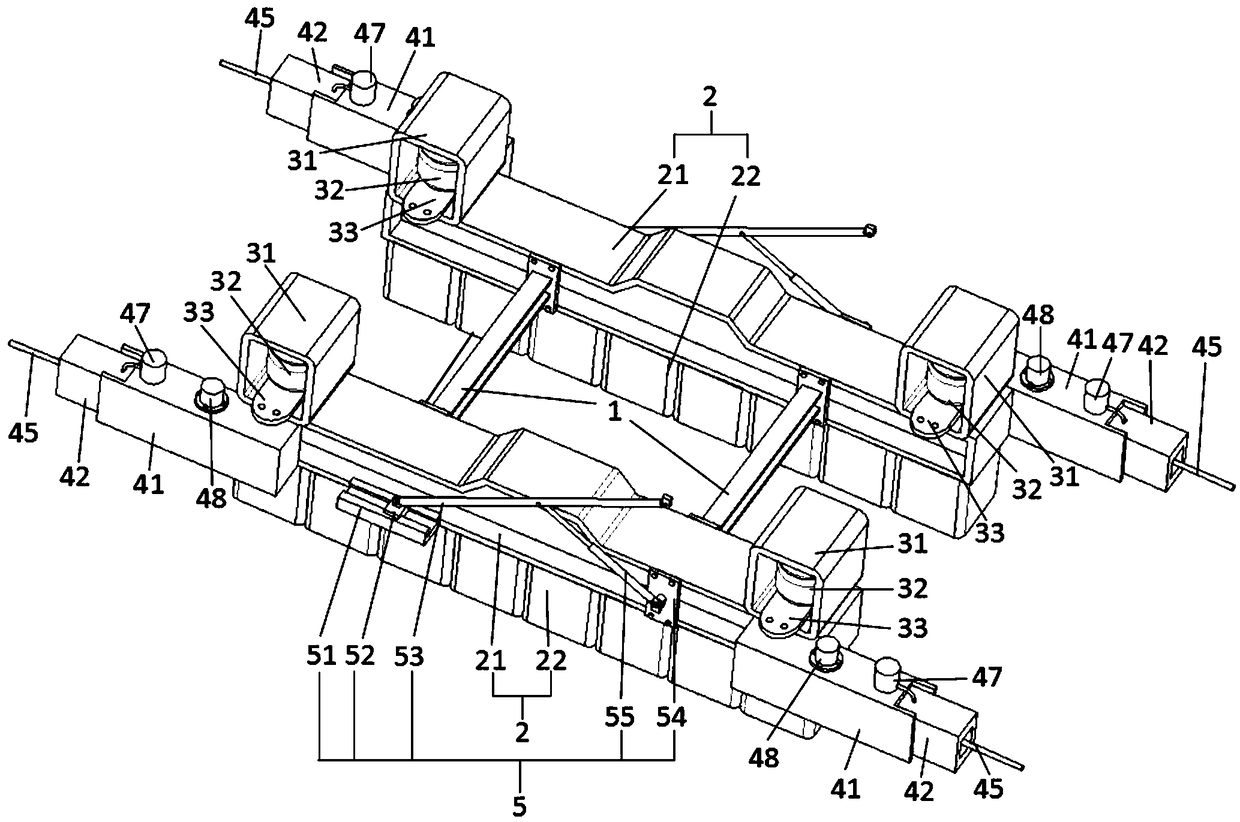

[0030] The invention is like Figure 1-3 As shown, it includes a connecting beam 1 and a pair of excitation units 2,

[0031] A pair of excitation units 2 are arranged side by side on both sides of the connecting beam 1, a pair of excitation units 2 are installed on the bogie (can be lifted and moved), and the excitation unit 2 includes a yoke beam 21 and a plurality of excitation windings 22;

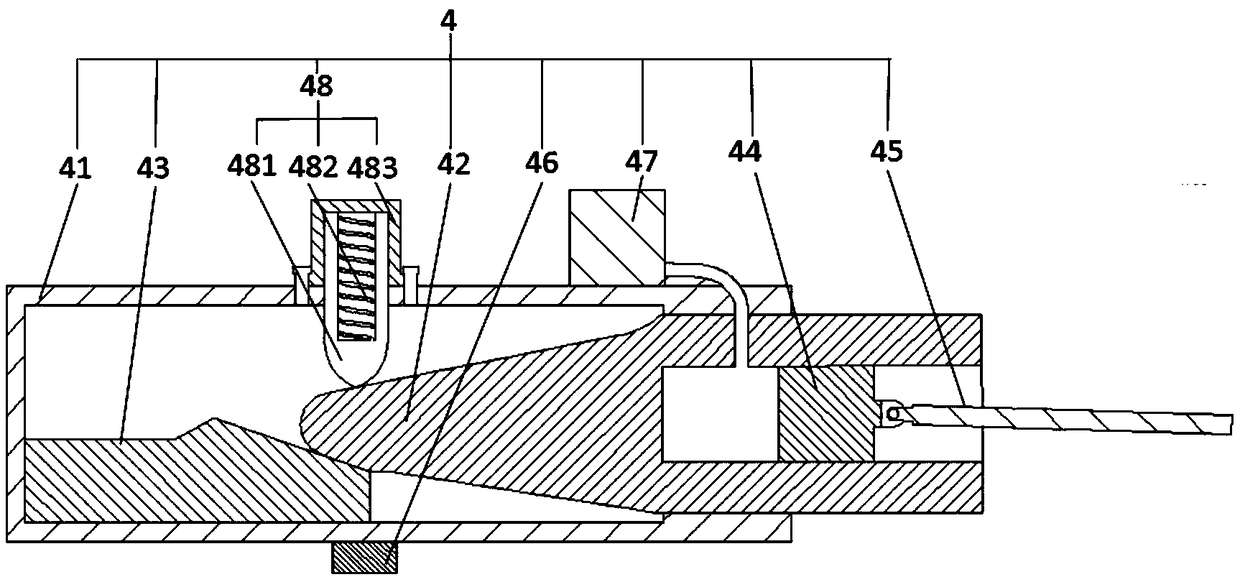

[0032] The front and rear ends of the excitation unit 2 are respectively provided with a lifting system 3 and an air gap adjustment system 4, and the lifting system 3 is located inside the air gap adjustment system 4;

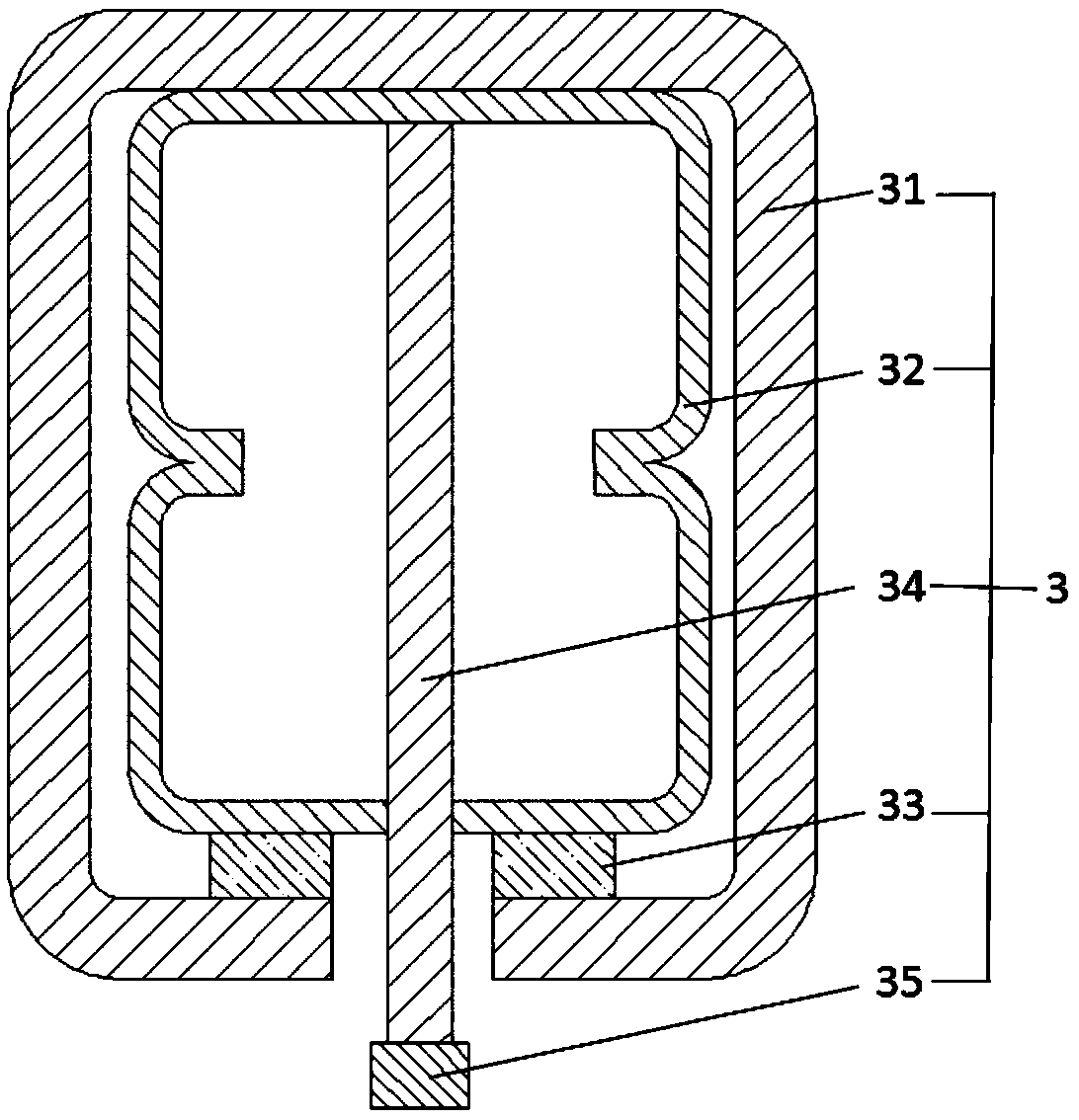

[0033] The lifting system 3 is used to drive the excitation unit 2. The lifting system 3 includes an outer cover 31, an air bag 32, a mounting plate 33, a piston rod 34, and a fixing block 35. The bottom of the outer cover 31 is provided with an opening, and the outer cover 31 It is fixedly connected to the mounting plate 33, and at the same time, the mounting plate is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com