Non-contact contact line geometrical parameter detecting method

A technology of geometric parameters and detection methods, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of poor system flexibility and low detection efficiency of contact line geometric parameters, and achieve system stability, good flexibility and adaptability, The effect of simple algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiment of the present invention will be described in further detail below in conjunction with the actual pictures taken in the experiment.

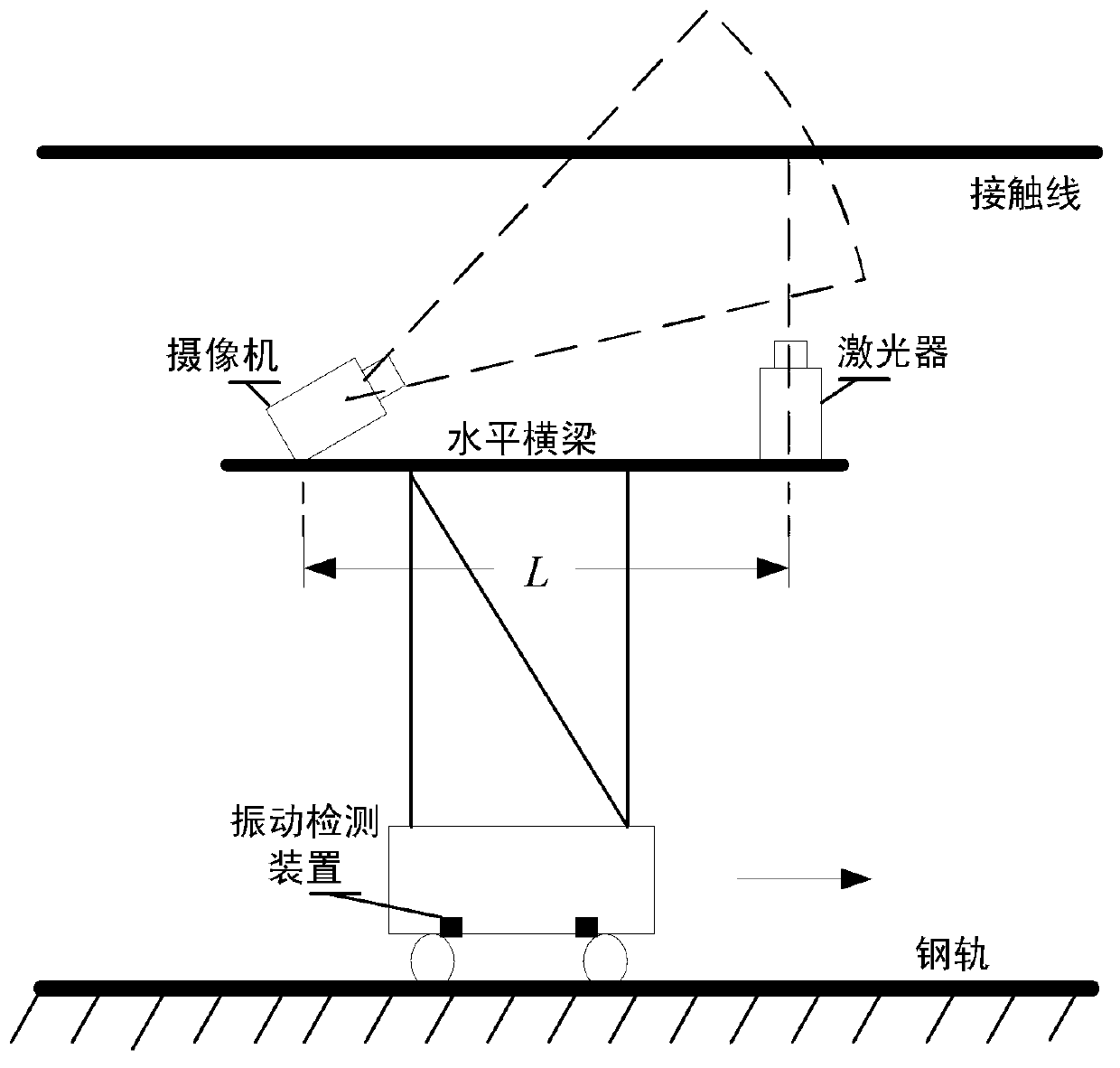

[0033] combine figure 1 As shown, it is a schematic diagram of the detection device of the present invention. The beam of the detection vehicle is located directly above the center line of the track; the vertical beam of the laser is facing upwards, and the emitted laser area is larger than the maximum pull-out value of the contact line; the CCD camera and the beam present a fixed angle.

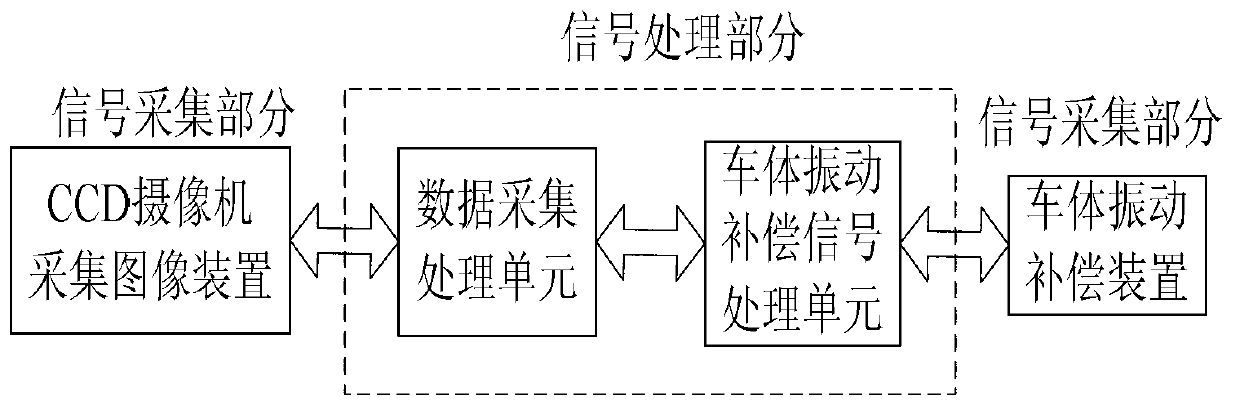

[0034] The working principle is: when the inspection vehicle is moving along the track, the laser emission line hits the contact line to form a brighter spot, and the CCD camera located at the rear end of the inspection vehicle will take pictures according to the set time interval. . With the difference of the height and position of the contact line, the position of the laser spot in the image has a corresponding presentation. By locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com