Floating type train brake pad capable of replacing friction block

A friction block, floating technology, applied in the direction of friction linings, brake types, brake components, etc., can solve problems such as inability to obtain maximum braking pressure, unbalanced braking pressure, and large effective friction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure example assembly process of the present invention is as follows:

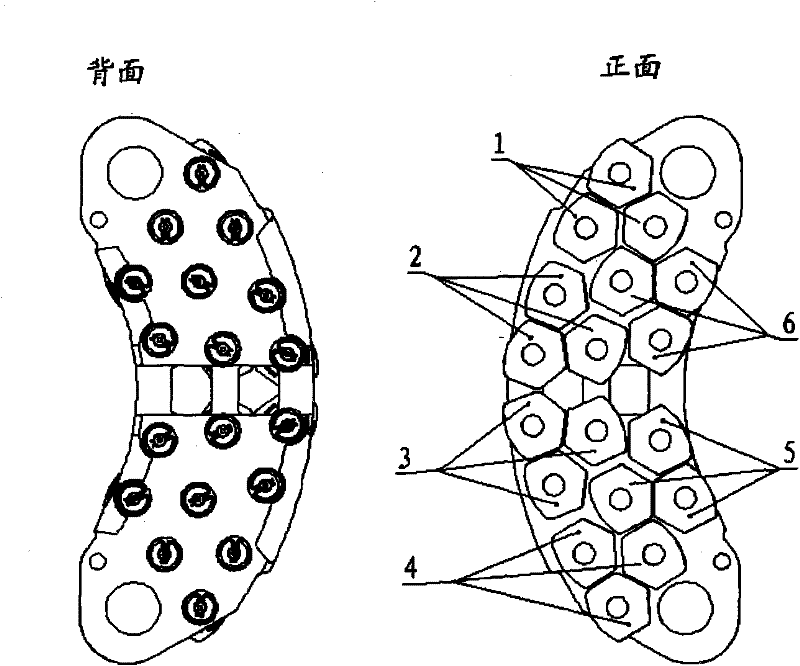

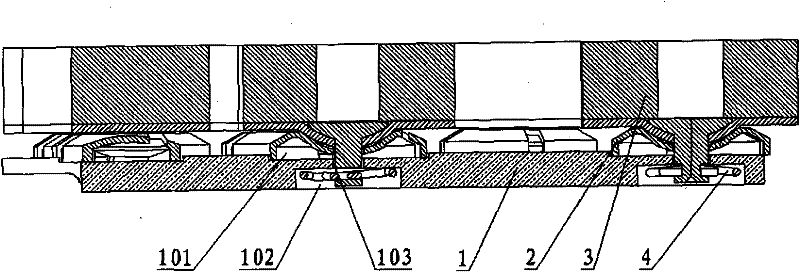

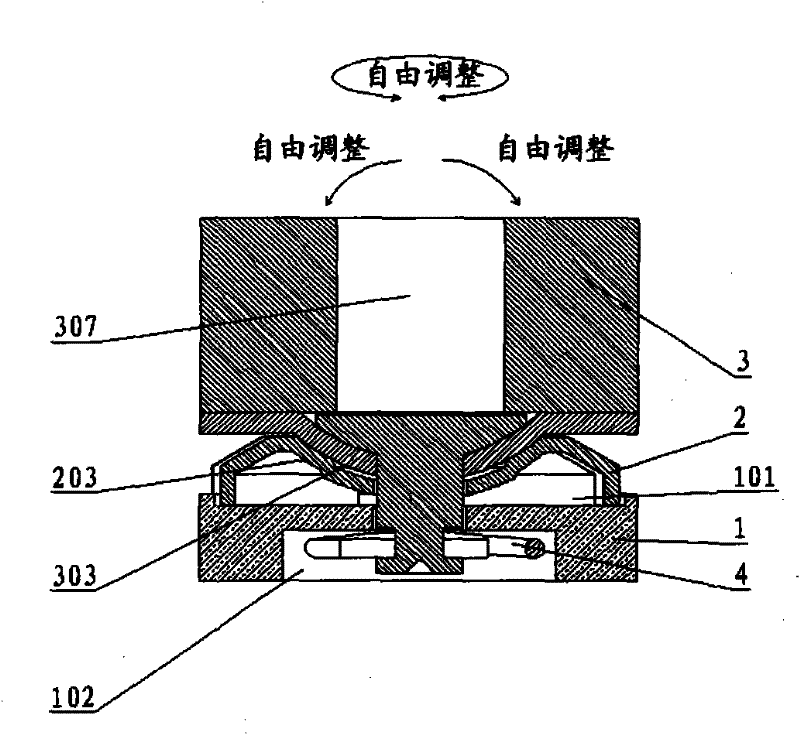

[0020] attached by figure 1 The back plate (1) of the brake pad is given. There are multiple single-arc quadrilateral friction blocks (3) connected to the positioning holes (103) on the back plate, and the positive plate of the back plate has a plurality of support plate spot-faced holes (101) , there are a plurality of spring clips spot facing holes (102) on the back side of the backboard. The fixed support pawl (201) of the elastic support piece (2) is placed in the spot-faced hole (101) of the support piece on the front of the backboard. The friction material (301) of the friction block is made of copper-based powder metallurgy material through vacuum pressure sintering. At the same time of sintering, the friction material and the friction block liner (302) together with the guide connecting shaft (305) should be sintered glued together. Pass the guide connection shaft (305) of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com