Aluminum alloy sheet for high-speed train structure and manufacture thereof

A technology of aluminum alloy sheet and high-speed train, applied in the field of aluminum alloy sheet and its manufacturing, can solve the problems of lack of systematic research, unsolved technical problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

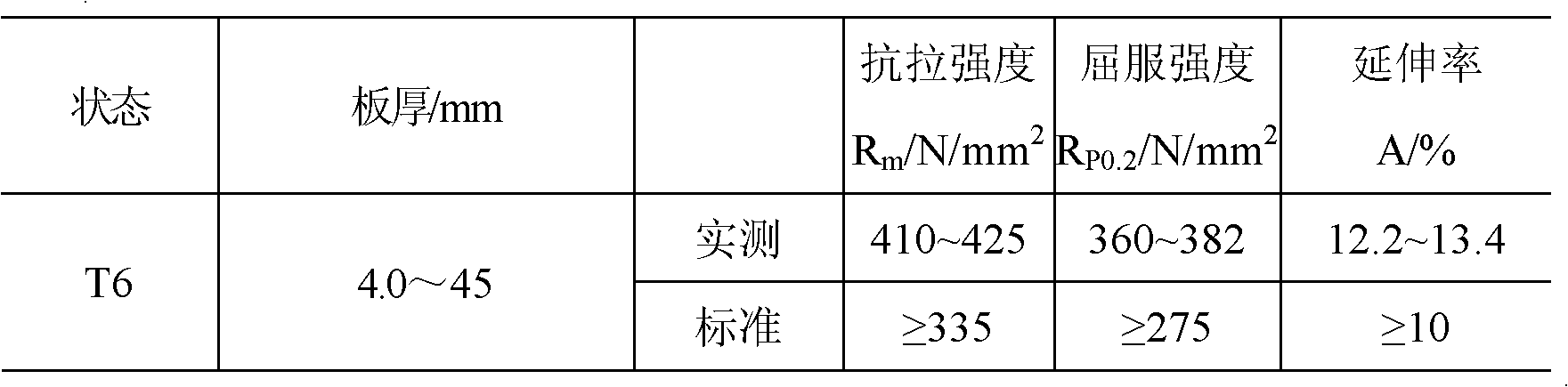

Examples

specific Embodiment approach 1

[0008] Specific Embodiment 1: In this embodiment, the mass percentages of the elements in the aluminum alloy plate for high-speed train structural parts are as follows: Zn: 3.5-6.0%, Mg: 1.2-3.0%, Mn: 0.3-0.9%, Crmass percent of Si.

specific Embodiment approach 2

[0009] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the mass percentages of the elements in the aluminum alloy sheet for high-speed train structural parts in this embodiment are as follows: Zn: 3.5%, Mg: 1.2%, Mn: 0.3%, Crthe mass percentage of Si.

specific Embodiment approach 3

[0010] Specific embodiment three: In this embodiment, the mass percentages of the elements in the aluminum alloy plate for high-speed train structural parts are as follows: Zn: 6.0%, Mg: 3.0%, Mn: 0.9%, CrSi .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com