Anti-shock support hanger

A technology for supporting hangers and hydraulic shock absorbers, applied in the directions of pipeline supports, springs/shock absorbers, shock absorbers, etc., can solve the problems of weak lateral and longitudinal stress capacity, low installation efficiency, complex structure, etc. Strong lateral and longitudinal stress capacity, high seismic safety factor, and the effect of seismic shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

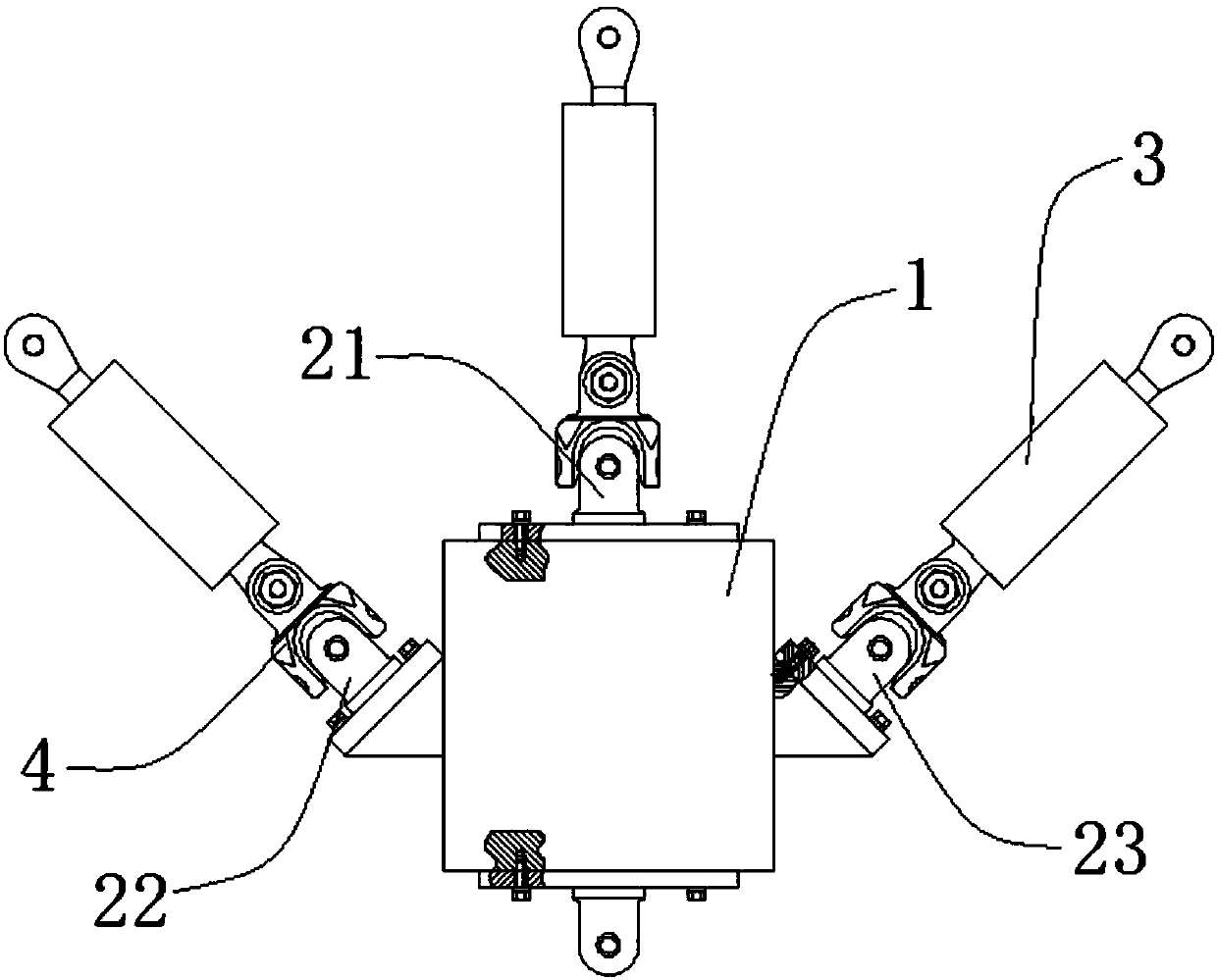

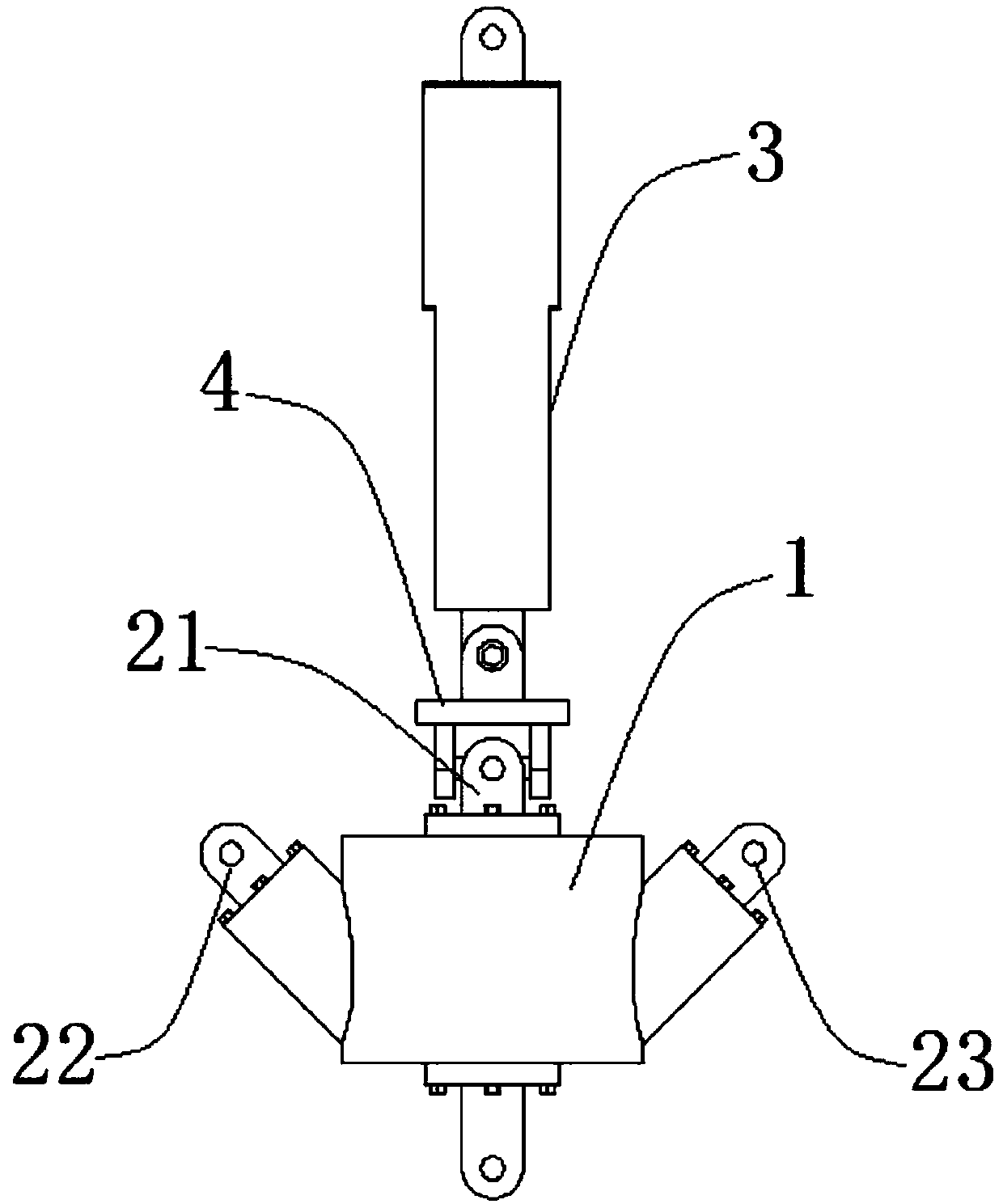

[0013] Such as Figure 1-2 As shown, the anti-seismic support and hanger includes a transfer module 1, a three-way transfer point connected to the transfer module 1, and a hydraulic shock absorber 3 connected to the transfer point. The contact and the hydraulic shock absorber 3 are connected by a universal connector 4; wherein the three-way transfer points are respectively the first transfer point 21, the second transfer point 22, and the third transfer point 23, and the first transfer point The contact point 21 is arranged above the adapter module 1 and is relatively vertically arranged, and the second adapter point 22 and the third adapter point 23 are arranged on two opposite sides of the adapter module 1, and both are inclined relative to the sides Set upwards with a 45° tilt angle.

[0014] The first transfer point 21 is fixed on the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com