Method for preparing high-hydroscopicity resin in homogeneous aqueous medium by using straw as raw material

A technology of superabsorbent resin and water medium, which is applied in the fields of fiber raw material processing, textiles and papermaking, etc., to achieve the effects of uniform distribution of product components, cost reduction, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

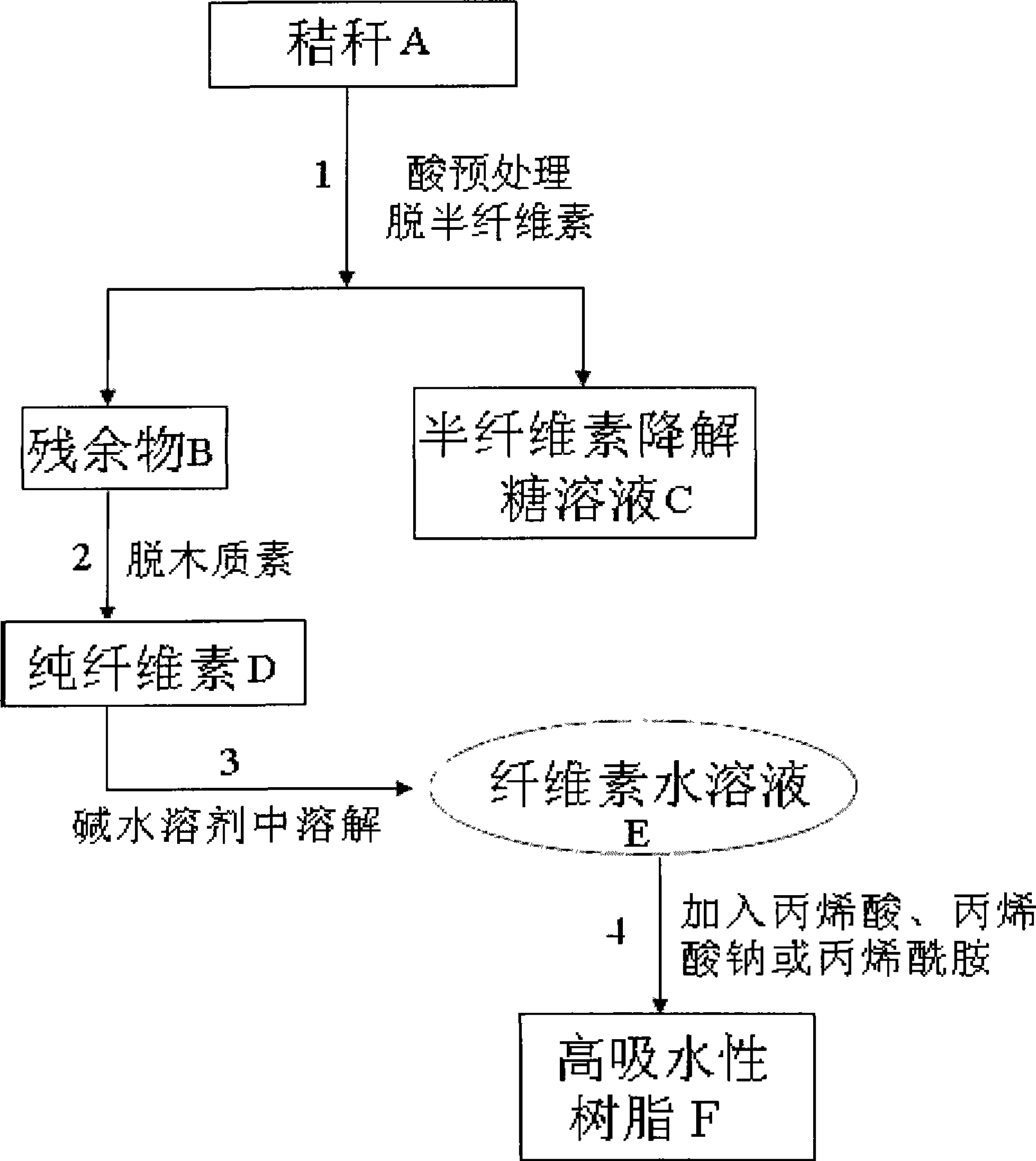

[0028] figure 1 The schematic flow chart of the present invention for separating cellulose from straw, preparing cellulose aqueous solution and preparing superabsorbent resin is given: the whole process is divided into four steps: first, carry out acid pretreatment on the raw material straw biomass A to remove half Cellulose, obtained by filtration and separation of hemicellulose degraded sugar solution C and residue B; followed by delignification of residue B to obtain pure cellulose D; and then using alkaline water solvent to dissolve the obtained cellulose to obtain fiber cellulose aqueous solution E; finally, with the cellulose aqueous solution as the main body, propylene-based monomers are added to carry out graft polymerization initiated by free radicals to obtain superabsorbent resin F. These four steps are interrelated, that is: the removal rate of hemicellulose in the first step should be greater than 80%, so as to ensure the smooth progress of the second step of deli...

Embodiment 2

[0037] With a molecular weight of 4.6×10 4 g / mol straw isolated cellulose as raw material. Take 0.2 grams of cellulose, 0.3 grams of sodium hydroxide, and 0.2 grams of urea, dissolve them at low temperature and prepare 5 grams of a solution, then introduce 0.2 grams of acrylamide, react at 55 ° C for 2 hours, and then 2 Add 0.004 g of K under atmosphere 2 S 2 o 8 , then raised the temperature to 60°C to initiate the grafting reaction for 15 minutes, cooled, neutralized to neutral with hydrochloric acid, added 0.66 grams of sodium acrylate, 0.3 grams of acrylamide, 0.004 grams of N, N'-methylenebisacrylamide, 0.008 Gram K 2 S 2 o 8 , then at N 2 Under atmosphere protection, react at 60°C for 1.5h, take out the block-shaped transparent gel, soak it in ethanol for 2 days, dehydrate, and dry at 80°C to obtain superabsorbent resin D.

Embodiment 3

[0039] With a molecular weight of 6.2×10 4 g / mol straw isolated cellulose as raw material. Take 0.2 g of cellulose and 0.3 g of sodium hydroxide, freeze at low temperature and melt at room temperature to obtain an aqueous solution of cellulose, add 0.2 g of acrylamide, react at 55 ° C for 2.5 h, cool, neutralize with hydrochloric acid until neutral, add Acrylamide 0.6 g, N,N'-methylenebisacrylamide 0.0045 g, K 0.009 g 2 S 2 o 8 , at N 2 Under the protection of atmosphere, react at 60°C for 2 hours, take out the block transparent gel, soak it in ethanol for 2 days, dehydrate, and dry at 80°C to obtain superabsorbent resin E.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water sorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com