Degradable biomedical material Zn-Si-X zinc alloy and preparation method

A biomedical material, zn-si-x technology, applied in electrolytic coating, metal material coating technology, medical science, etc., can solve the problem of loss of mechanical integrity, fast corrosion of magnesium alloy, and incomplete function of implants Play and other issues to achieve the effect of good histocompatibility and blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] A method of preparing a degradable biomedical material Zn-Si-X-cyclic alloy, the preparation method comprising the steps of:

[0057] Select the elemental composition and element content of the Zn-Si-X-Z-Z-zinc alloy of the biomedical material, and the corresponding feedstock is weighed and mixed according to the selected element composition and the element content, and mixed to obtain a mixture, in CO 2 SF 6 Under the protective atmosphere, the aforementioned mixture is smelted or sintered, and the degradable biomedical material Zn-Si-X-Z Zinc alloy is obtained by obtaining a porous structure after cooling.

[0058] In particular, the preparation method comprises the steps of:

[0059] Select the elemental composition and element content of the Zn-Si-X-Z-Z-zinc alloy of the biomedical material, and the corresponding feedstock is weighed and mixed according to the selected element composition and the element content, and mixed to obtain a mixture, in CO 2 SF 6 Under the pro...

Embodiment 1

[0086] A method of preparing a degradable biomedical material Zn-Si-X-Z-Z-Z zinc alloy, the specific steps are as follows;

[0087] Pure Zn (99.99wt.%), Pure Si (99.95wt.%), Pure X (X is Ga, Ge, Cu, Ag, Mn, Mg, Ca, Sr, Fe, Ti, Zr, Sn, Y, Nd At least one element in YB) (purchased from Beijing Cuiberin Nonferrous Metallic Metal Technology Development Center) as a raw material, mixed according to different quality, in CO 2 + Sf 6 Under the protective atmosphere, smelting at 600 ° C, after the raw material is sufficiently melted, after holding 10 min, the circulating water is rapidly cooled to prepare Zn-Si-X-Zinc alloy ingot.

Embodiment 2

[0089] A method of preparing a degradable biomedical material Zn-Si-X-Z-Z-Z zinc alloy, the specific steps are as follows;

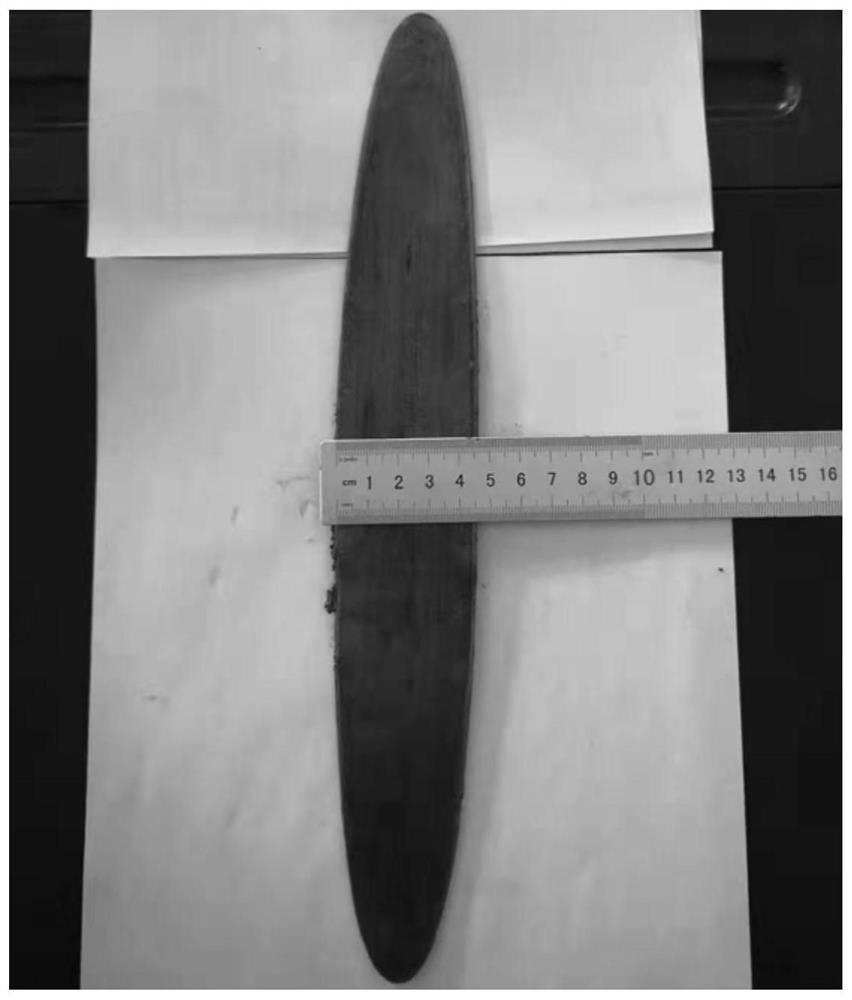

[0090] First Step in Example 1 was prepared according to the zinc Zn-Si-X based alloy ingot; and the above-described Zn-Si-X to obtain a zinc-based alloy hot-rolled ingot, ingot preheated to 250 deg.] C, and then hot The rolling mode is repeated rolled in a round-trolling mill, and the temperature rolled temperature is 250 ° C, and finally in the finishing mill, it rolled to 1.5 mm thickness at 250 ° C ( figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com