Nano calcium phosphate salt/polymer directional hole composite material and preparation method

A nano-calcium phosphate and composite material technology, which is applied in the field of antibiotic drug carrier materials and preparation, can solve the problems of lack of performance antibiotic carrier materials, and achieve the effect of avoiding pain and reducing economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

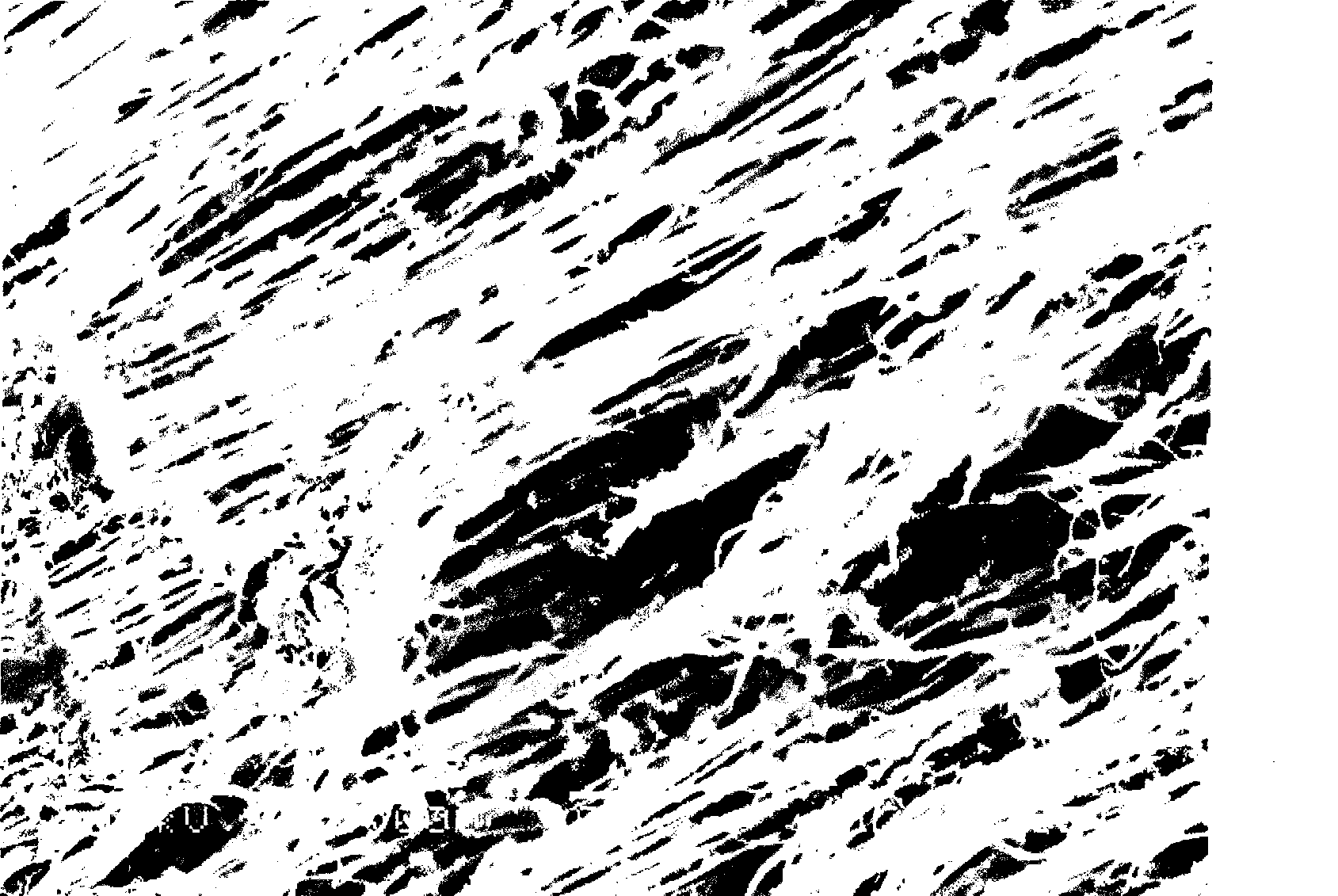

Image

Examples

Embodiment 1

[0022] Calcium acetate (CH 3 COO) 2 Ca) and phosphoric acid (H 3 PO 4 ) as precursors of calcium and phosphorus respectively, 21.3927 g (CH 3 COO) 2 Ca was dispersed in 100 ml of absolute ethanol system, and then 9.8 g of H was added dropwise under vigorous stirring. 3 PO 4 , the solution was adjusted to pH ≥ 9 with 5 mol / L NaOH, stirred at 30°C for 12 hours to form a stable milky white sol, then filtered and dried at 80°C for 12 hours, collected and ground to obtain Tricalcium phosphate powder with an average particle size of 80 nm.

[0023] Dissolve 5 grams of polycaprolactone with a molecular weight of 70,000 in 20 milliliters of tetrahydrofuran, add 1 gram of surfactant Span80 and 2 milliliters of water, and then add 1 gram of tricalcium phosphate obtained by the above method under vigorous stirring at 30°C Nano powder, continue to stir at high speed for 10 hours to form a metastable colloidal system; inject the colloid into a 15ml plastic centrifuge tube with a con...

Embodiment 2

[0025] The preparation of the tricalcium phosphate nanopowder is the same as in Example 1.

[0026] Dissolve 5 grams of polycaprolactone with a molecular weight of 70000 in 20 milliliters of tetrahydrofuran, add 1 gram of surfactant Span80 and 2 milliliters of water, then add 1 gram of tricalcium phosphate nanopowder under vigorous stirring at 30°C, Continue high-speed stirring for 10 hours to form a metastable colloidal system; inject the colloid into a 15 ml plastic centrifuge tube with a conical bottom, clamp it on a device that can precisely control the lifting rate, and expose the bottom of the plastic centrifuge tube to liquid nitrogen The liquid level then drops at a rate of 50 mm / h until the colloid is completely submerged in liquid nitrogen, then stops falling and maintains this state for 3 hours, and freeze-dries for 72 hours after taking it out to obtain a nano-phosphate triphosphate with an average pore size of 3 microns. Calcium / Polycaprolactone Oriented Pore Comp...

Embodiment 3

[0028] The preparation of the tricalcium phosphate nanopowder is the same as in Example 1.

[0029] Dissolve 5 grams of polycaprolactone with a molecular weight of 70000 in 20 milliliters of tetrahydrofuran, add 1 gram of surfactant Span80 and 2 milliliters of water, then add 1 gram of tricalcium phosphate nanopowder under vigorous stirring at 30°C, Continue high-speed stirring for 10 hours to form a metastable colloidal system; inject the colloid into a 15 ml plastic centrifuge tube with a conical bottom, clamp it on a device that can precisely control the lifting rate, and then expose the bottom of the plastic centrifuge tube to liquid nitrogen The liquid level then drops at a rate of 100 mm / hour until the colloid is completely submerged in liquid nitrogen, then stops falling and maintains this state for 3 hours, and freeze-dries for 72 hours after taking it out to obtain a nano-phosphate triphosphate with an average pore size of 5 microns. Calcium / Polycaprolactone Oriented ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com