Nanocellulose-polypyrrole-polyvinyl alcohol composite conductive hydrogel as well as preparation method and application thereof

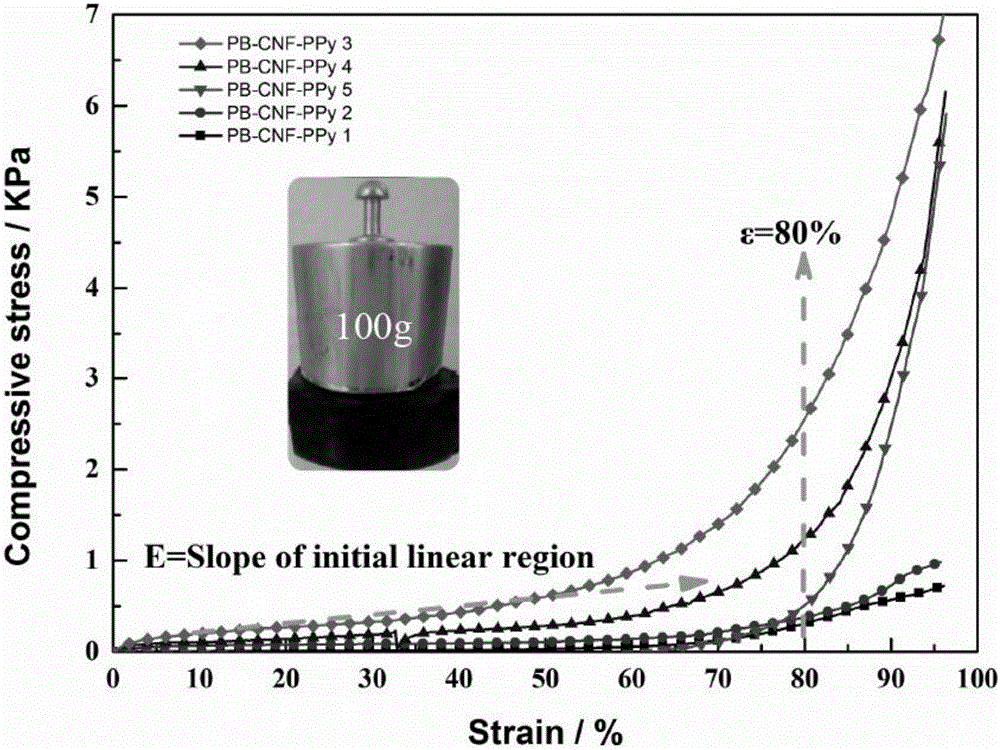

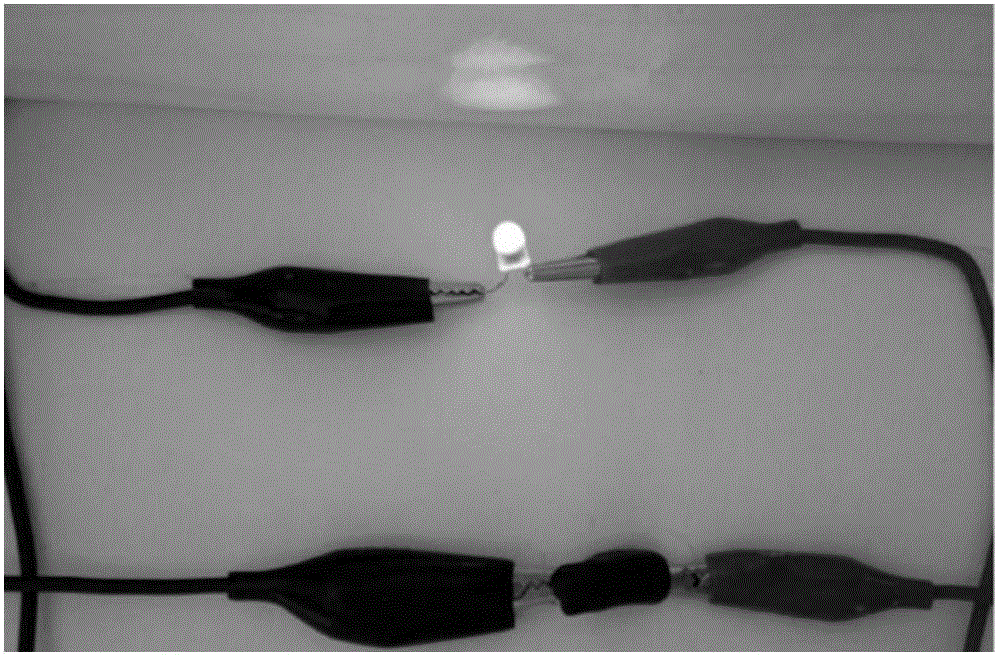

A technology of nanocellulose and polyvinyl alcohol, which is used in fiber raw material processing, textile and papermaking, etc., can solve the problem of nanocellulose-polypyrrole-polyvinyl alcohol composite conductive hydrogel that does not have good mechanical properties and electrical conductivity. and other problems, to achieve the effects of good mechanical properties, improved mechanical strength, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] In step 1, the cellulose is prepared into nanocellulose through chemical and mechanical treatment, and the specific method steps include:

[0084] (1) Chemical treatment method:

[0085] 1) Add 204g of deionized water to the beaker, weigh 196g of concentrated sulfuric acid with a mass fraction of 98%, drain the concentrated sulfuric acid with a glass rod and slowly add it to the deionized water, stir magnetically for 12 hours, and cool to room temperature to prepare 400g of concentrated sulfuric acid with a mass fraction of 48 % of sulfuric acid for standby;

[0086] 2) The temperature of the taken sulfuric acid oil bath is stabilized to 44-45°C, and the stirring is continued;

[0087] 3) Weighing 20g of bleached wood pulp fiber, adding in batches to 400g of sulfuric acid solution with a mass fraction of 48% continuously stirred;

[0088] 4) After one hour of reaction, a large amount of deionized water was added to terminate the reaction. The obtained suspension was ...

Embodiment 2

[0104] In step 1, the cellulose is prepared into nanocellulose through chemical and mechanical treatment, and the specific method steps include:

[0105] (1) Chemical treatment method:

[0106] 1) Add 204g of deionized water to the beaker, weigh 196g of concentrated sulfuric acid with a mass fraction of 98%, drain the concentrated sulfuric acid with a glass rod and slowly add it to the deionized water, stir magnetically for 12 hours, and cool to room temperature to prepare 400g of concentrated sulfuric acid with a mass fraction of 48 % of sulfuric acid for standby;

[0107] 2) The temperature of the taken sulfuric acid oil bath is stabilized to 44-45°C, and the stirring is continued;

[0108] 3) Weighing 20g of bleached wood pulp fiber, adding in batches to 400g of sulfuric acid solution with a mass fraction of 48% continuously stirred;

[0109] 4) After one hour of reaction, a large amount of deionized water was added to terminate the reaction. The obtained suspension was ...

Embodiment 3

[0125] In step 1, the cellulose is prepared into nanocellulose through chemical and mechanical treatment, and the specific method steps include:

[0126] (1) Chemical treatment method:

[0127] 1) Add 204g of deionized water to the beaker, weigh 196g of concentrated sulfuric acid with a mass fraction of 98%, drain the concentrated sulfuric acid with a glass rod and slowly add it to the deionized water, stir magnetically for 12 hours, and cool to room temperature to prepare 400g of concentrated sulfuric acid with a mass fraction of 48 % of sulfuric acid for standby;

[0128] 2) The temperature of the taken sulfuric acid oil bath is stabilized to 44-45°C, and the stirring is continued;

[0129] 3) Weighing 20g of bleached wood pulp fiber, adding in batches to 400g of sulfuric acid solution with a mass fraction of 48% continuously stirred;

[0130] 4) After one hour of reaction, a large amount of deionized water was added to terminate the reaction. The obtained suspension was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average density | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com