Preparation method of cellulose nanofiber

A nanofiber and cellulose technology, applied in the field of resources, can solve the problems of environmental pollution and safety risks caused by strong acids, strong bases and toxic reagents, and achieve the effects of simple and safe reagents, increased molecular accessibility, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

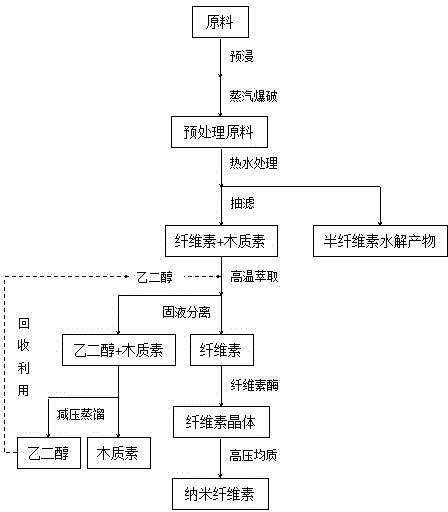

Method used

Image

Examples

Embodiment 1

[0028] Soak 2-10mm long corn stalks in water until saturated, then put them into a steam explosion tank, hold the pressure for 10 minutes under a pressure of 1.8Mpa, and then release the pressure instantly to obtain steam-exploded corn stalks; add steam to the reaction kettle Exploded corn stalks and water, the mass ratio of steam-exploded corn stalks and water is 1:8, hydrolyzed at 180°C for 20 minutes, and after cooling, use vacuum pump to filter to obtain hydrolyzate and steam-exploded straw filter residue; steam-exploded straw filter residue After washing with water, place it in an autoclave, then add 80% ethylene glycol solution at a solid-to-liquid ratio of 1:7, heat to 210°C for extraction for 2.5 hours, and perform solid-liquid separation after cooling to obtain the extraction solution and cellulose solid; the extraction solution is distilled under reduced pressure to obtain ethylene glycol solution and lignin, in which ethylene glycol can be reused for circular extract...

Embodiment 2

[0030] Soak the bran in water until the water is saturated, then put it into a steam explosion tank, maintain the pressure under the pressure of 2.2Mpa for 5 minutes, and then release the pressure instantly to obtain the steam explosion bran; add the steam explosion bran and water into the reaction kettle , the mass ratio of steam-exploded bran and water is 1:10, hydrolyzed at a temperature of 190°C for 10 minutes, and after cooling, use a vacuum pump to carry out suction filtration to obtain hydrolyzate and steam-exploded bran filter residue; steam-exploded bran filter residue is washed with water After filtering, put it in a high-pressure reactor, then add 80% ethylene glycol solution at a solid-to-liquid ratio of 1:8, heat to 215°C for extraction for 2 hours, and perform solid-liquid separation after cooling to obtain the extraction solution and cellulose solid; The extraction solution is distilled under reduced pressure to obtain ethylene glycol solution and lignin, in whic...

Embodiment 3

[0032] Soak the bean dregs in water until the water is saturated, then put them into a steam explosion tank, maintain the pressure at a pressure of 1.5Mpa for 12 minutes, and then release the pressure instantly to obtain steam-exploded bean dregs. The mass ratio of bean dregs to water is 1:16, hydrolyzed at 170°C for 30 minutes, and then filtered with a vacuum pump after cooling to obtain the hydrolyzate and steam-exploded bean dregs filter residue; the steam-exploded bean dregs filter residue is washed with water and then subjected to high-pressure reaction In the still, add 90% ethylene glycol solution with a mass concentration of 90% according to the solid-to-liquid ratio of 1:9, heat to 200°C for extraction for 2 hours, and conduct solid-liquid separation after cooling to obtain the extraction solution and cellulose solid; the extraction solution is distilled under reduced pressure Finally, ethylene glycol solution and lignin are obtained, wherein ethylene glycol can be reu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com