Method for preparing nanocellulose by using homogeneous method

A nano-cellulose, homogeneous method technology, applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of high production costs, difficult recovery of acid-base reagents, high energy consumption, etc., to achieve easy recycling and large-scale industrialization The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

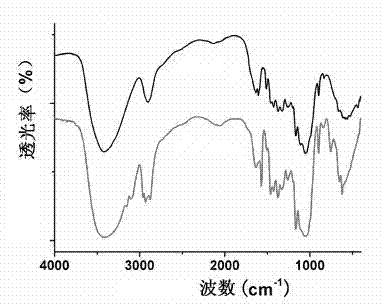

Image

Examples

Embodiment 1

[0025] Sodium hydroxide solution (volume concentration of 3%) was added to bagasse and treated at 80°C for 60 min, wherein the mass ratio of bagasse to sodium hydroxide solution was 1:15.

[0026] The treated bagasse is pulverized and passed through a 60-100 mesh sieve. Then add 1-butyl-3-methylimidazolium chloride ionic liquid to it, and place it in a microwave device with a power of 500w, under the condition of 140 oC, mechanically stir for 60min to obtain a cellulose homogeneous solution, the sugarcane The mass ratio of slag to 1-butyl-3-methylimidazolium chloride ionic liquid is 1:99. The obtained homogeneous solution was homogenized 10 times at 100 MPa in a shearing homogenizer. The obtained solution was poured into ethanol while stirring to precipitate cellulose, the volume ratio of the solution to ethanol was 1:4, centrifuged for precipitation, washed with ethanol for several times, and spray-dried to obtain nanocellulose. The length of the nanocellulose obtained in t...

Embodiment 2

[0029] Sodium hydroxide solution (volume concentration of 5%) was added to bagasse, and treated at 90°C for 60 min, wherein the mass ratio of bagasse to potassium hydroxide solution was 1:10.

[0030] The treated bagasse is pulverized and passed through a 60-100 mesh sieve. Then add 1-butyl-3-methylimidazolium chloride ionic liquid to it, and place it in a microwave device with a power of 400w, under the condition of 120oC, mechanically stir for 110min to obtain a homogeneous solution of cellulose, the bagasse The mass ratio with 1-butyl-3-methylimidazolium chloride ionic liquid is 1:20. The obtained homogeneous solution was added to a shearing homogenizer and homogenized 20 times at 80 MPa. The obtained solution was poured into water while stirring to precipitate cellulose, and the volume ratio of the solution to water was 1:8, centrifuged for precipitation, washed with water for several times, and vacuum freeze-dried to obtain nanocellulose. The length of the nanocellulose...

Embodiment 3

[0033] Potassium hydroxide solution (volume concentration of 2%) was added to the cotton pulp, and treated at 85oC for 90 minutes, wherein the mass ratio of cotton pulp to potassium hydroxide solution was 1:15.

[0034] The treated cotton pulp is pulverized and passed through a 60-100 mesh sieve. Then add 1-butyl-3-methylimidazolium chloride ionic liquid to it, and place it in a microwave device with a power of 400w, under the condition of 130 oC, mechanically stir for 100min to obtain a homogeneous solution of cellulose, the cotton The mass ratio of pulp to 1-butyl-3-methylimidazolium chloride ionic liquid was 1:15. The obtained homogeneous solution was added to a shearing homogenizer and homogenized 15 times at 120 MPa. The obtained solution was poured into ethanol while stirring to precipitate cellulose, and the volume ratio of the solution to ethanol was 1:6, centrifuged for precipitation, washed with ethanol for several times, and vacuum freeze-dried to obtain nanocellul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com