Method for high-efficiency hydrolyzing lignocellulose raw material in ionic liquid

A lignocellulosic raw material and ionic liquid technology, which is applied in fiber raw material processing, textile and papermaking, and bulk chemical production, can solve the problems of hydrolysis of lignocellulosic raw materials, cumbersome hydrolysis steps, and large amount of acid, etc., and achieve Low requirements for corrosion resistance, low cost, and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

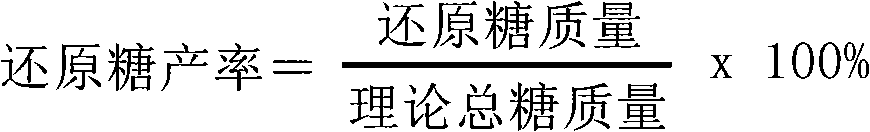

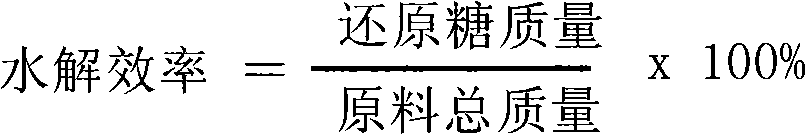

Embodiment 1

[0028]Add 4 g of ionic liquid BMImCl into a 10 ml round bottom flask, heat to 100°C, slowly add 0.2 g of 40 mesh corn stalks under vigorous stirring, and stir until all soluble parts are completely dissolved. At this point, 0.03 g of water and 0.04 g of concentrated hydrochloric acid (36 wt%) were quickly added to the reaction system in sequence, and reacted at 100° C. for 30 minutes under normal pressure. After the reaction is finished, quench the reaction with cold water, adjust the pH value of the reaction solution to 7.0 with 0.5 mol / L NaOH, and measure the reducing sugar content of the obtained hydrolyzate by DNS method. The resulting reducing sugar yield and hydrolysis efficiency were 66% and 43%, respectively.

Embodiment 2~3

[0030] Other process conditions and experimental steps are the same as in Example 1, but using concentrated hydrochloric acid (36wt%) of different qualities as a catalyst, and quenching the reaction at different times, the results are shown in Table 1. The experimental results show that the increase of acid amount can accelerate the hydrolysis rate.

[0031] Table 1 Hydrolysis reaction results of corn stalks catalyzed by different qualities of hydrochloric acid

[0032] project

Embodiment 4~5

[0034] Other process conditions and experimental steps are the same as in Example 1, but the quality of water added is 0.1 gram and 0.2 gram respectively. The hydrolysis reaction was terminated at different times, and the results are shown in Table 2. The experimental results show that the increase of the amount of water as a reactant can lead to a significant decrease in the reaction rate, but the yield of reducing sugar is increased. This is because the increase in the amount of water in the reaction system leads to a decrease in acid concentration and milder reaction conditions, which slow down the degradation of reducing sugars.

[0035] Influence law of water content on hydrolysis result in table 2 reaction system

[0036] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com