Preparation method and use for ultra-hydrophobic cotton fibrous material or ultra-hydrophobic paper fibrous material

A fiber material and paper fiber technology, which is applied in the field of preparation of cellulose materials, can solve the problems of reduced gas permeability, limitation, and reduced water absorption effect, and achieves the effect of good hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

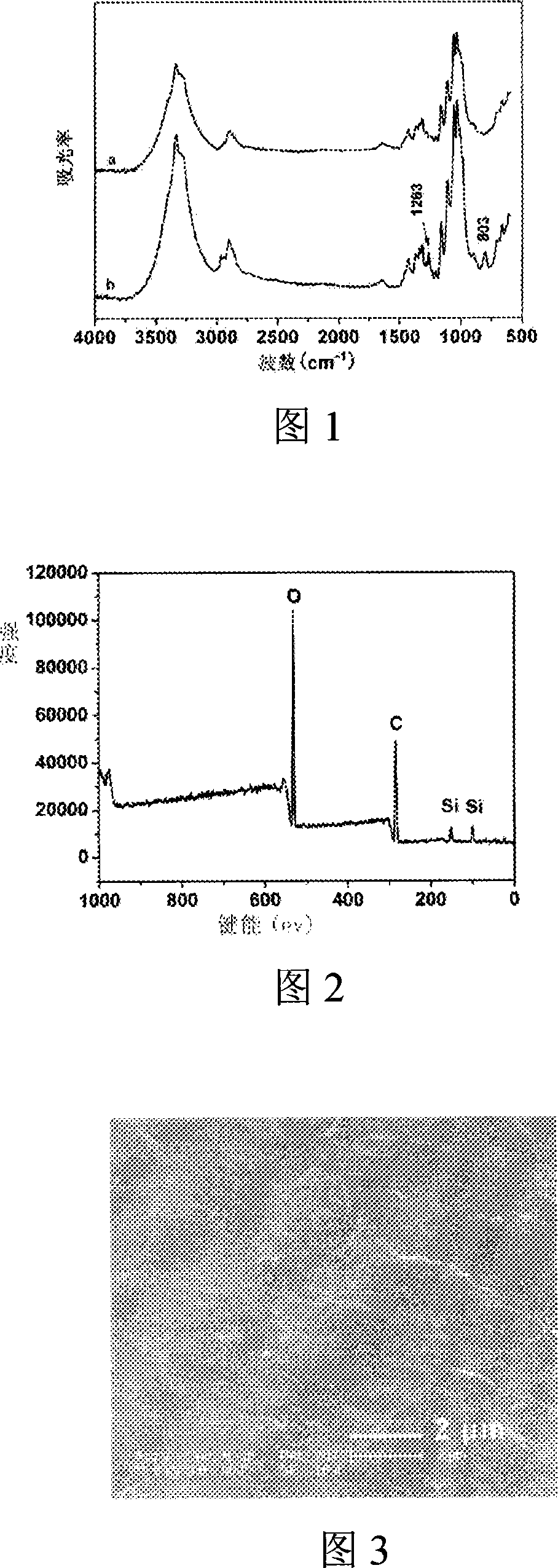

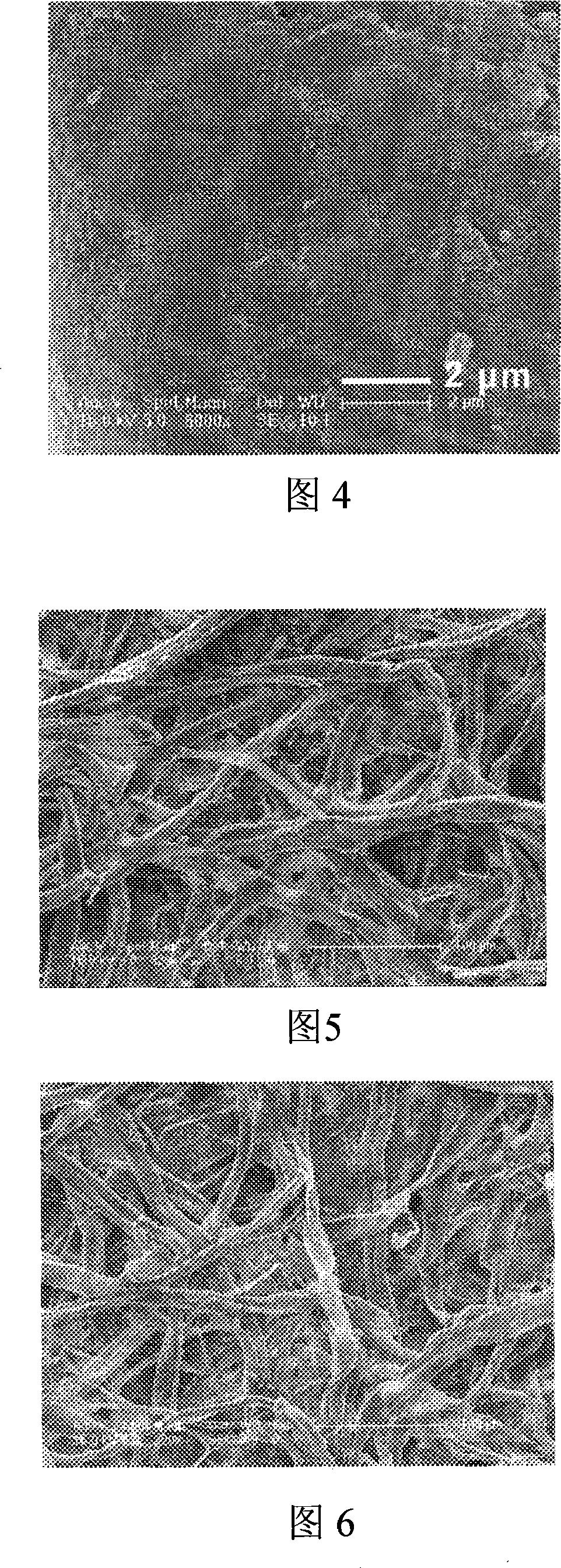

[0031] Embodiment 1: According to the ratio of the amount of substances, it is the ratio of sodium methyl silicate / carbon dioxide=1: 6-50, and carbon dioxide gas is passed into the sodium methyl silicate aqueous solution whose mass fraction is 0.1%-5%, to prepare Colloidal solution of methyl silicate. According to the mass ratio of filter paper / methyl silicic acid colloid solution = 1 / 2-50, soak the filter paper in the methyl silicic acid colloid solution, take it out after 5-10 minutes, wash it with water, and put it in a temperature of 120-180 ℃ Heat treatment in an oven for 5-30 minutes to obtain filter paper with superhydrophobic properties.

Embodiment 2

[0032] Embodiment 2: Potassium methyl silicate is used to replace sodium methyl silicate, and the method of Example 1 is used to obtain filter paper with superhydrophobic properties.

Embodiment 3

[0033] Example 3: Replace the filter paper with kraft paper, facial tissue, cotton or pure cotton knitwear respectively, and use the method of Example 1 to process to obtain superhydrophobic facial tissue, cotton or pure cotton knitwear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com