Method for extracting cellulose from straw

A cellulose and straw technology, applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of difficult bleaching, high requirements, and insufficient paper tenacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

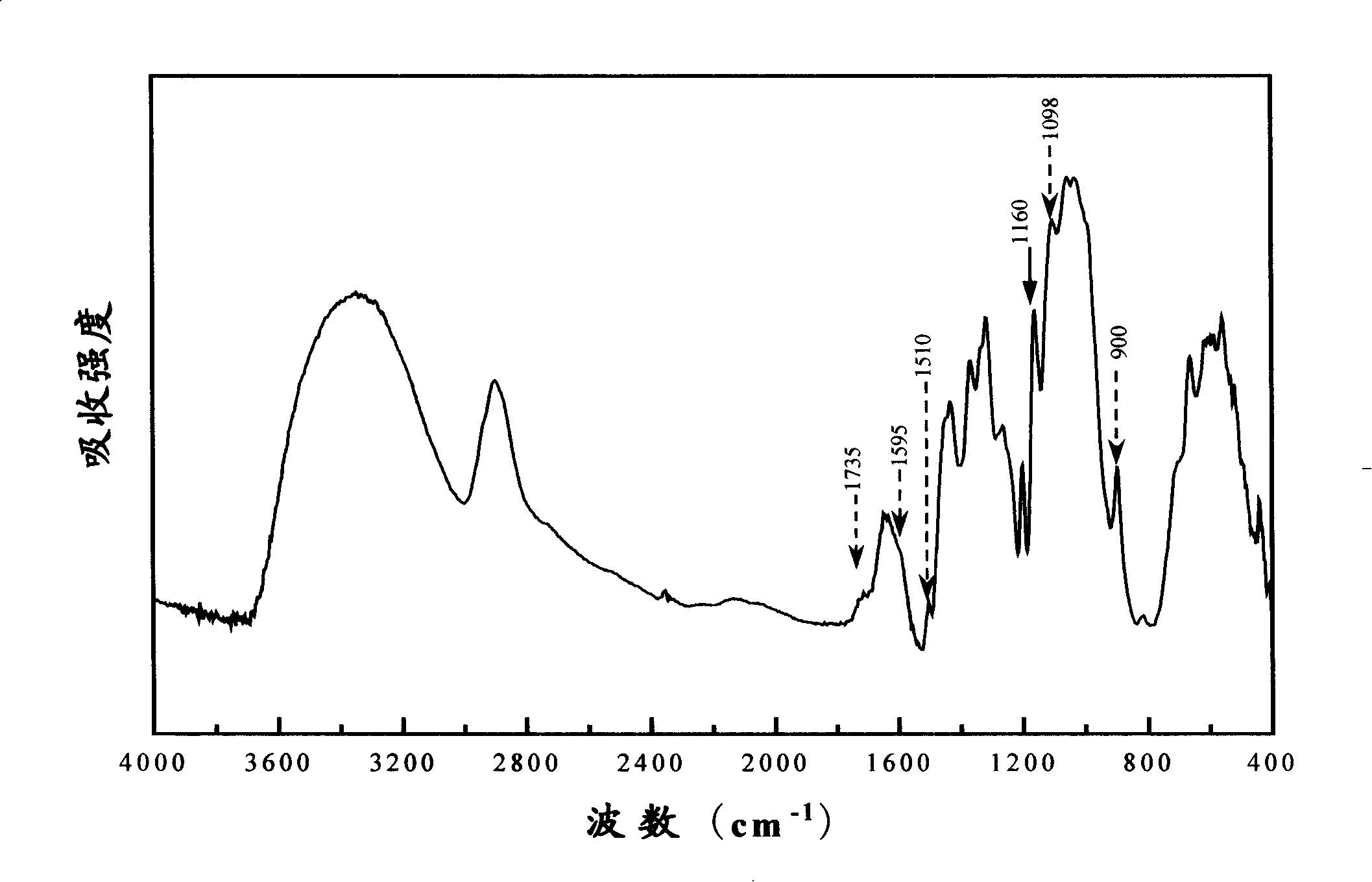

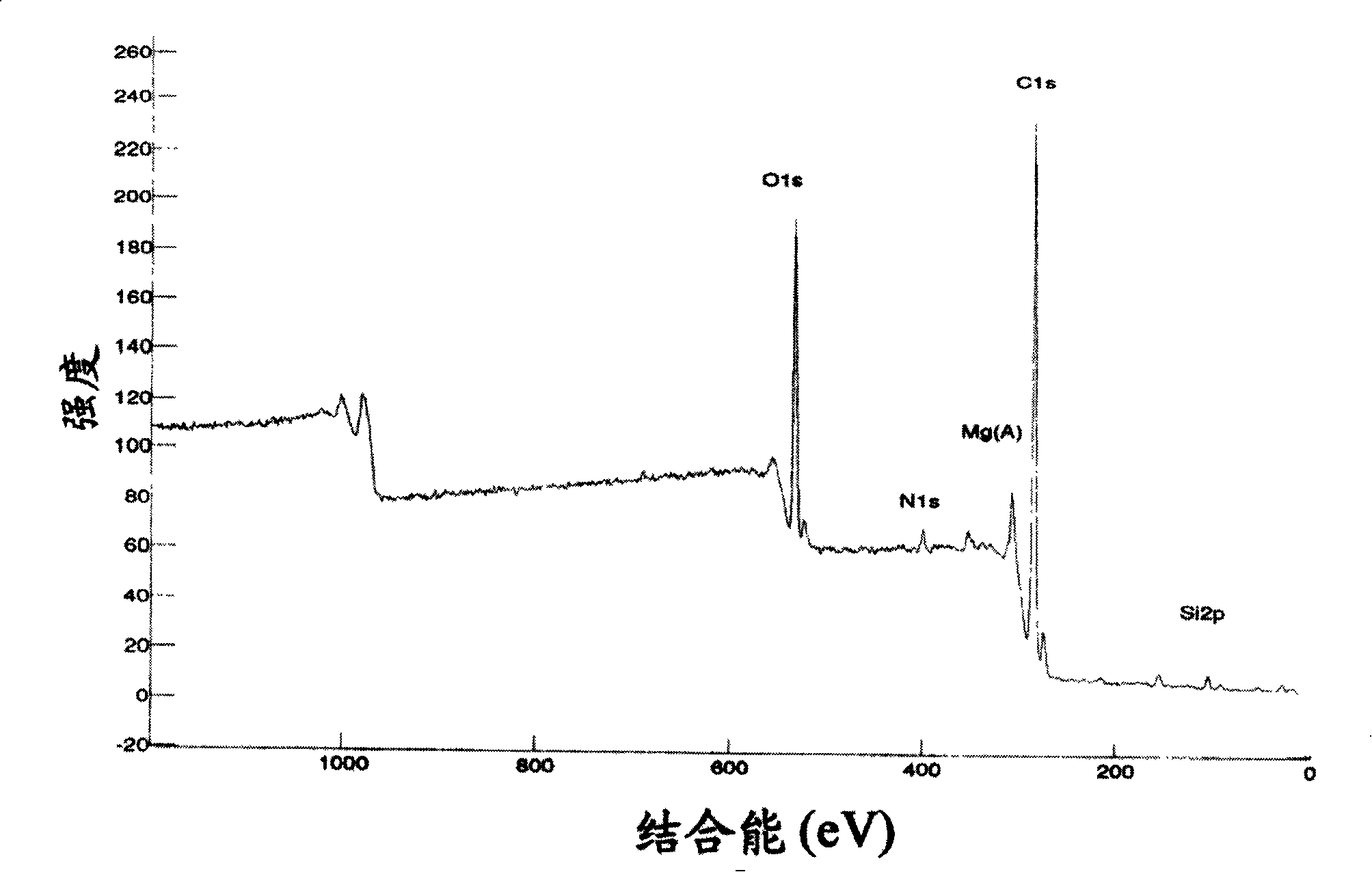

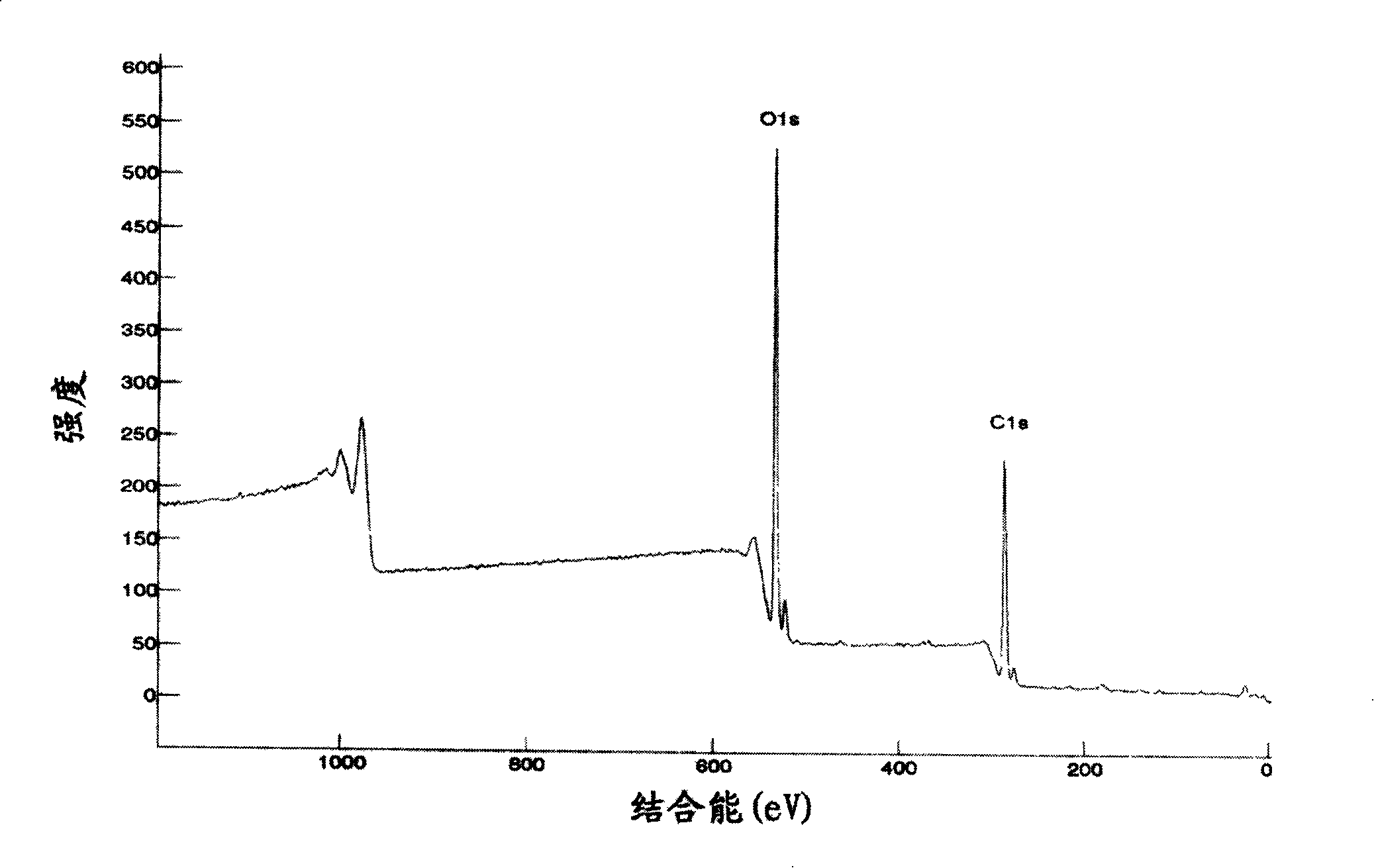

Embodiment 1

[0028] The 20g wheat straw after pulverizing (removing the nodular part of the straw containing a large amount of silicon) was put into a Soxhlet extractor and extracted with 200ml volume ratio of 1: 1 mixed solution of toluene and ethanol for 24 hours, and then used 180 ml of 5% KOH solution was soaked in the extracted product for 12 hours, stirring slightly during this process. Then the obtained sample was filtered with suction, the filtrate was recovered, and the filtered product was washed with water for 3 times, then filtered with suction again and dehydrated. The obtained product was soaked in 150 ml of 0.4% sodium chlorite solution for 6 hours, and the pH value of the solution in which the sample was placed was adjusted to about 5.0 with slight stirring. Then the obtained product was suction-filtered, continued to be put into 5% KOH solution for overnight treatment, and the solid in the solution was filtered out. Rinse well with water until the pH value is neutral, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com