Mechanical and jet flow combined exploitation method and mechanical and jet flow combined exploitation device for natural gas hydrates in non-stratified rock of shallow strata in seabed

A combined mining and hydrate technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of easy collapse of natural gas hydrate layers, low efficiency of broken and fluidized collection, and low strength of sediment structure. , to achieve the effect of enhancing strength, preventing collapse, and increasing the crushing radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

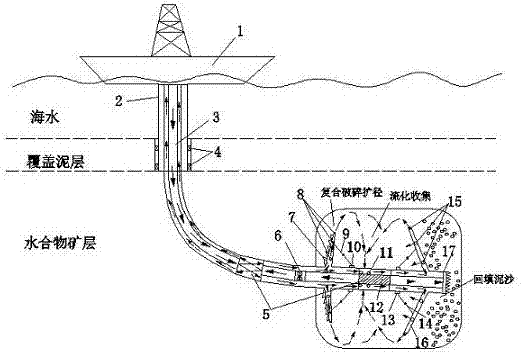

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

[0017] The seabed shallow non-diagenetic natural gas hydrate mechanical jet combined mining method described in the examples of the present invention mainly includes the following steps:

[0018] Step S1: lower the water-resisting conduit 2, the intelligent directional drilling tool 17 drills through the hole, and drives the flexible double-layer pipe 3 to drill downward. When the drilling reaches the working depth, the intelligent directional drilling tool 17 drills horizontally to the predetermined Location;

[0019] Step S2: Pull back the intelligent guiding drilling tool 17, and at the same time unfold the crushing knife arm 7, through the rotation of the knife arm and the jet nozzle 8 at the front end of the knife arm, jointly break the hydrate ore body, and open the rectification device 16 to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com