IGCC (integrated gasification combined cycle) system for capturing CO2 by integrated oxygen ion transmission membrane oxygen-enriched combustion method

A technology of oxygen ion transport membrane and integrated oxygen ions, which is applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of large oxygen demand, increased energy consumption of air separation units, and decreased system efficiency, and achieve energy consumption Reduce, reduce exergy loss, facilitate the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

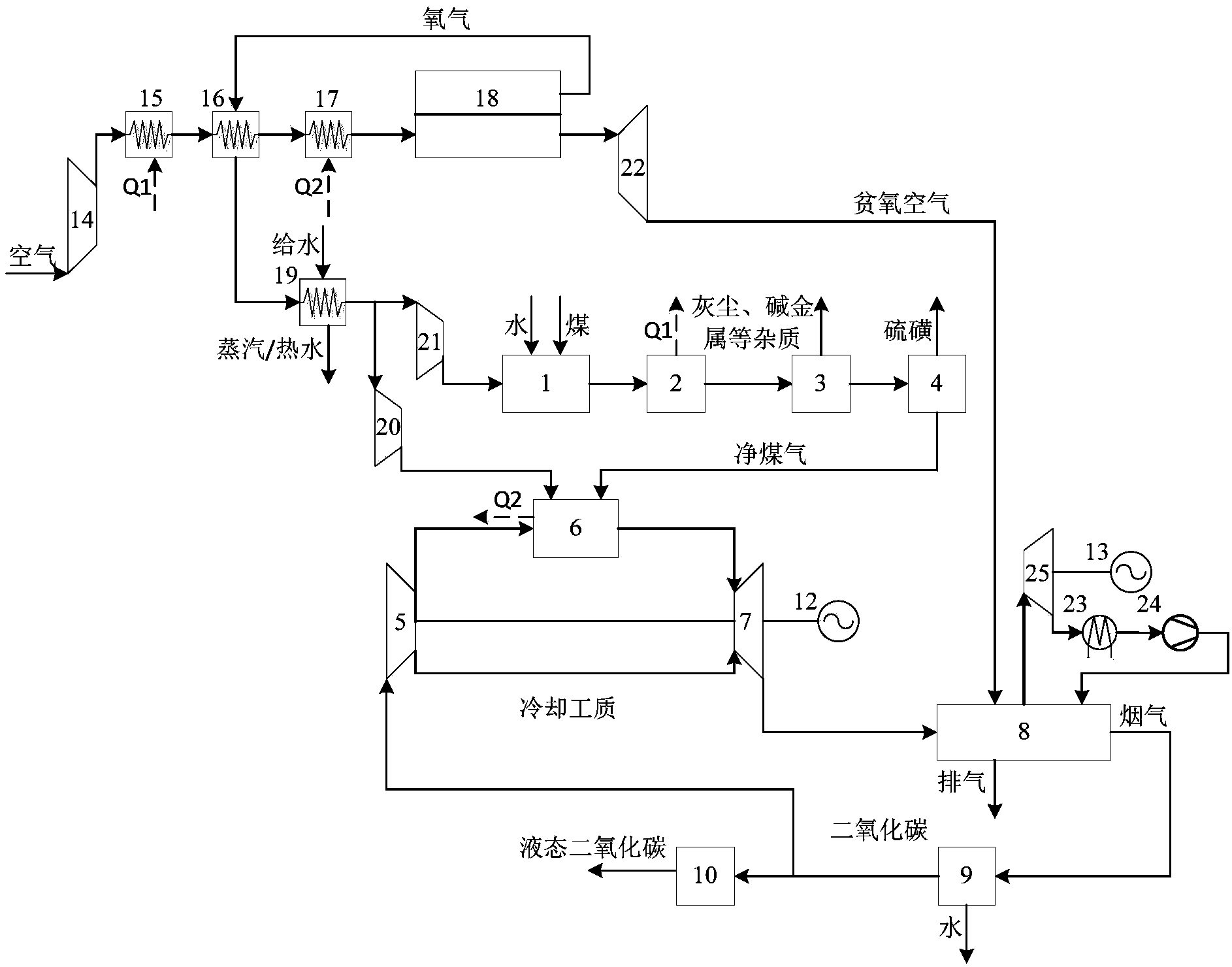

[0019] The invention provides an integrated oxygen ion transport membrane oxygen-enriched combustion method to capture CO 2 The IGCC system of the present invention will be further described below through the accompanying drawings and specific implementation methods.

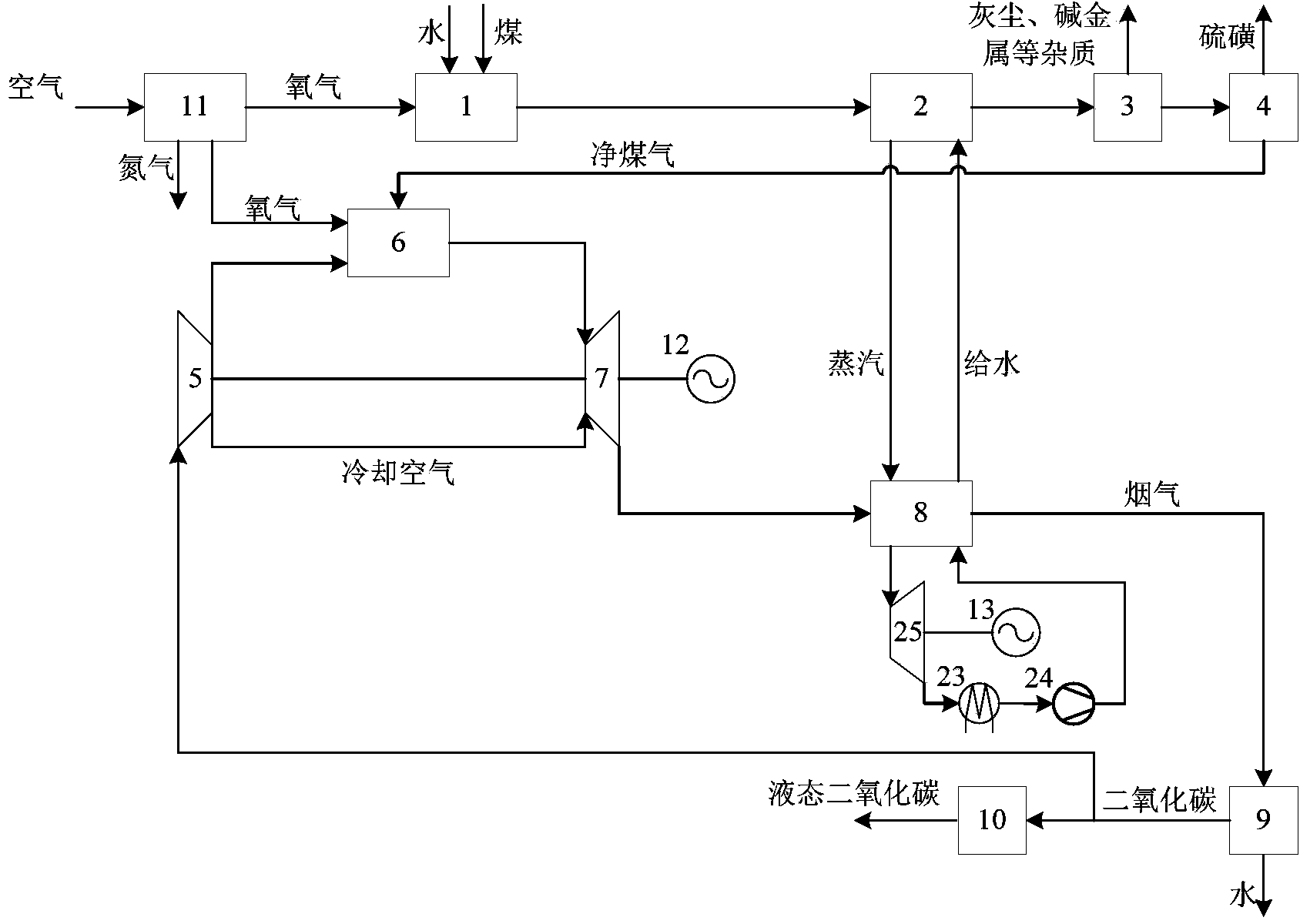

[0020] The flow chart of the benchmark system is as figure 1 As shown: after the air is separated by the cryogenic air separation unit 11, the separated oxygen is divided into two paths, one path directly enters the combustion chamber 6 of the gas turbine, and the other path enters the coal gasification unit 1 after being mixed with water and coal, and then passes through the gas After cooler 2, dust removal unit 3, and acid gas removal unit 4, the synthesized clean gas enters the combustion chamber 6 of the gas turbine for combustion, and the combustion exhaust gas expands through the gas turbine 7 to drive the first generator 12 to generate electricity, and then passes through the waste heat boiler 8 The gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com