Retirement composite insulator surface cleaning system

A composite insulator and surface cleaning technology, which is applied to cleaning methods and tools, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as difficult to clean and decommissioned composite insulator surface contamination deposition, to achieve efficient cleaning, improve The removal rate and the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

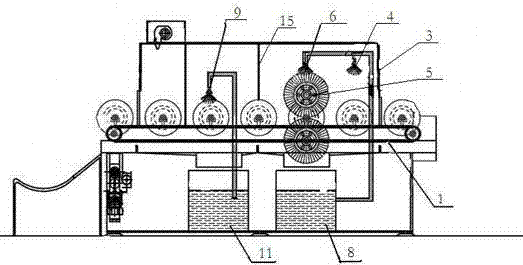

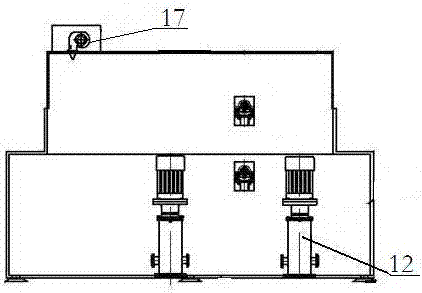

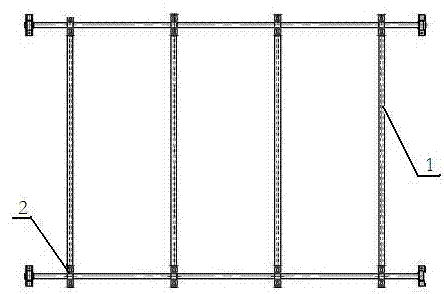

[0021] like figure 1 Shown, the present invention comprises conveying device and is positioned at the cleaning device above conveying device, combines below Figure 1-4 Describe each part in detail.

[0022] The conveying device includes a conveying chain 1 and a limit attachment for placing decommissioned composite insulators arranged on the conveying chain 1; preferably, the limit attachment is a limit block 2, and each conveying chain is provided with four limit The number of limit blocks can also be flexibly selected as 3 or 2 according to the actual situation. In principle, the number of limit blocks is 2-4 to ensure work efficiency; limit blocks are used to place decommissioned The end face of the composite insulator has a shape suitable for the retired composite insulator, such as a circular arc design, so as to support the outer insulating sheath of the retired composite insulator and ensure the continuous operation of the cleaning process.

[0023] Specifically, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com