High temperature heat storage system

A heat storage system and high temperature technology, applied in the field of energy storage, can solve the problems of low heat storage efficiency, achieve the effects of improving heat storage efficiency, avoiding mixing, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

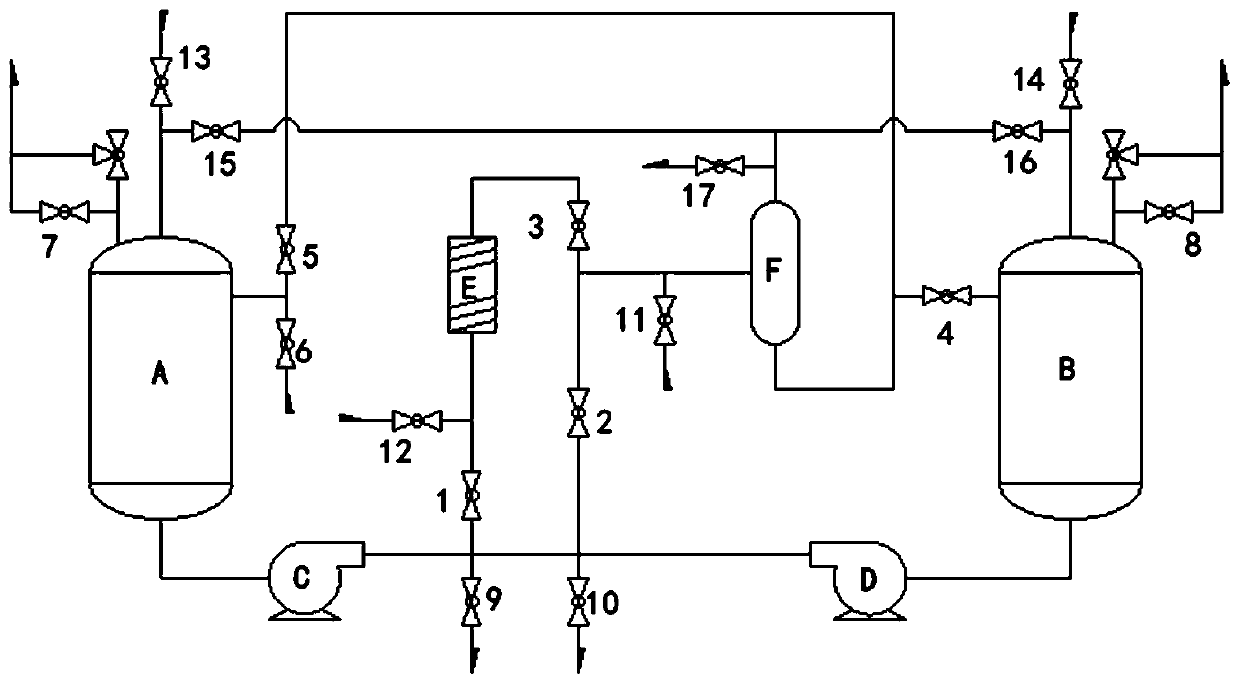

[0031] Such as figure 1 As shown, the present invention provides a high-temperature heat storage system, which includes a low-temperature tank A, a high-temperature tank B, a heat tracer E and a gas-liquid separator F, wherein the exhaust port and the inlet of the low-temperature tank A and the high-temperature tank B The liquid ports are preferably arranged at the tops respectively, and the liquid outlets of the low-temperature tank A and the high-temperature tank B are preferably arranged at the respective bottoms; the exhaust ports of the low-temperature tank A, the high-temperature tank B and the gas-liquid separator F are all provided with exhaust valves , that is to say, the outlet of the low-temperature tank A is provided with a low-temperature exhaust valve 7, the outlet of the high-temperature tank B is provided with a high-temperature exhaust valve 8, and the outlet of the gas-liquid separator F is provided with a gas Liquid exhaust valve 17; the first liquid inlet v...

Embodiment 2

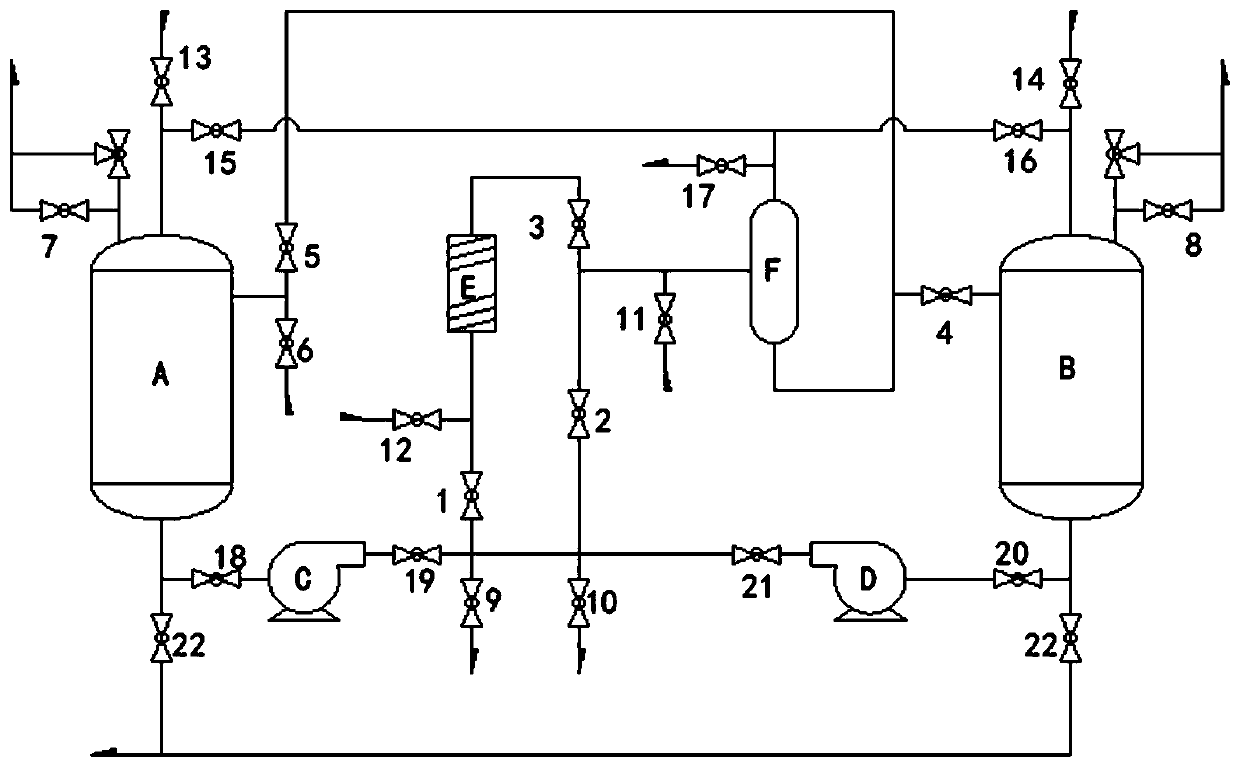

[0063] Such as figure 2 As shown, the structure and principle of the high-temperature heat storage system described in this embodiment are the same as those in Embodiment 1, and will not be repeated in this embodiment. The difference is that, in order to avoid the impact of the heat storage fluid on the cryopump C and the high temperature pump D during shutdown, the inlet and outlet of the cryopump C are provided with a sixth valve 18 and a seventh valve 19 respectively, and the outlet of the cryopump C The seventh valve 19 communicates with the inlet of the first valve 1, the second valve 2 and the first heat exchange valve 9 respectively; the inlet and outlet of the high temperature pump D are respectively provided with an eighth valve 21 and a ninth valve 20, and the high temperature pump D The outlet of D communicates with the inlets of the first valve 1 , the second valve 2 and the second heat exchange valve 10 respectively through the ninth valve 20 .

[0064] Preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com