Treatment method for phenolic water produced by gas producer

A gas generator and treatment method technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of gas explosion, large investment in equipment, increased energy consumption, etc., and achieve effective Conducive to utilization, low operating costs, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

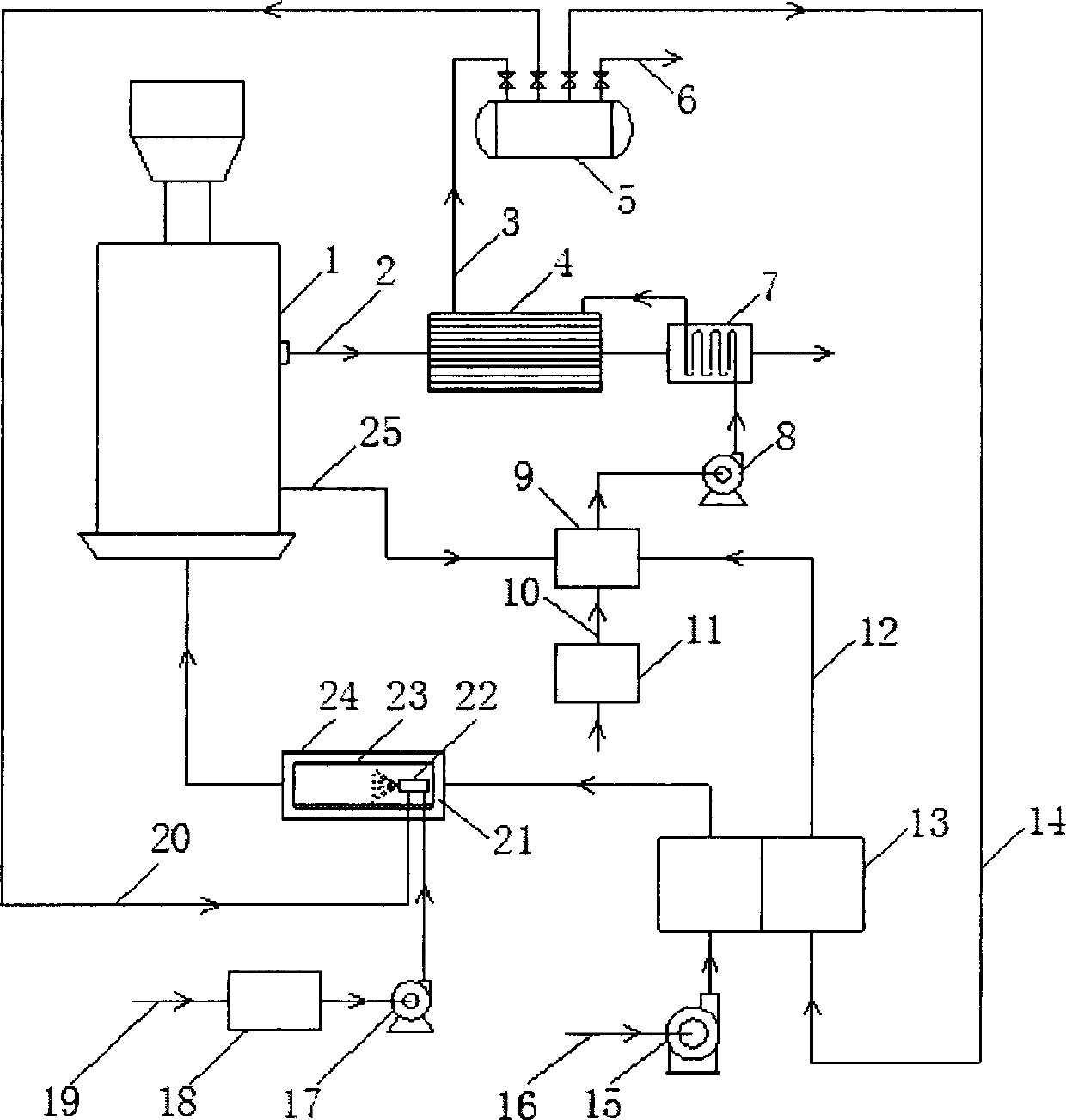

[0015] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0016] In the embodiment shown in the drawings, the high-temperature gas 2 from the lower section of the gas generator 1 enters the waste heat boiler 4, and the heat is transferred to the feed water in the waste heat boiler in the waste heat boiler 4 to generate high-temperature steam 3, and then the high-temperature steam 3 enters the waste heat boiler. Drum 5. The cold air 16 enters the air channel of the steam-air heat exchanger 13 through the blower 15, and in the steam-air heat exchanger 13, the heated air from the sub-steam drum 5 transfers heat to the air with the steam 14, and the air is heated to be heated. The heated hot air enters the mixing chamber 21, and at the same time, the steam 14 for the heated air entering the steam channel of the steam-air heat exchanger 13 is condensed into condensed water, and the condensed water 12 enters the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com