Method and equipment for manufacturing cigarettes by filamentization of tobaccos reconstituted by papermaking process

A technology for reconstituting tobacco leaves and making paper, applied in the field of cigarette manufacturing, can solve problems such as waste of environmental resources, and achieve the effects of reducing waste, reducing loss and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is preferably specifically described below through examples, but the protection scope of the present invention is not limited thereto.

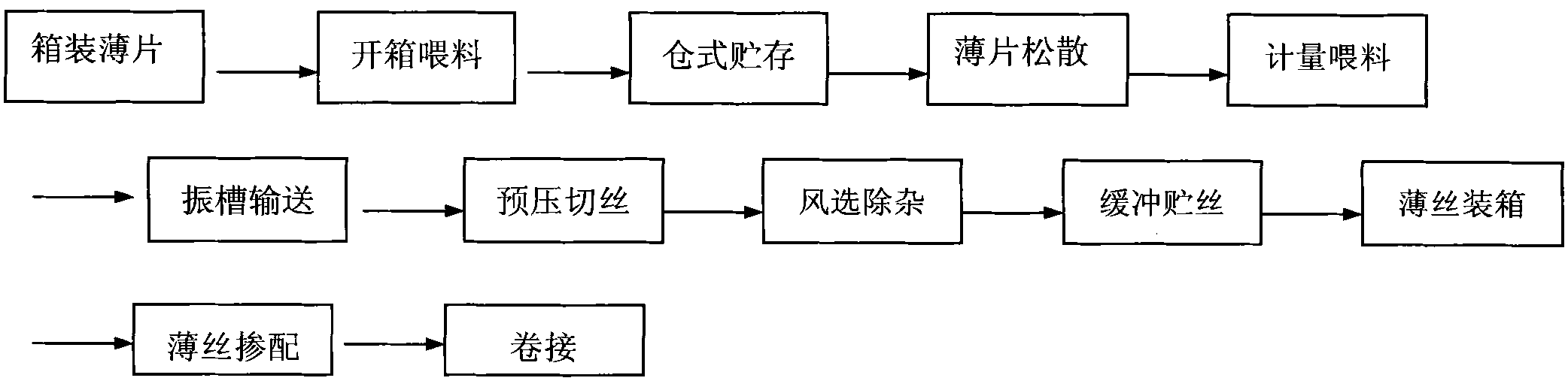

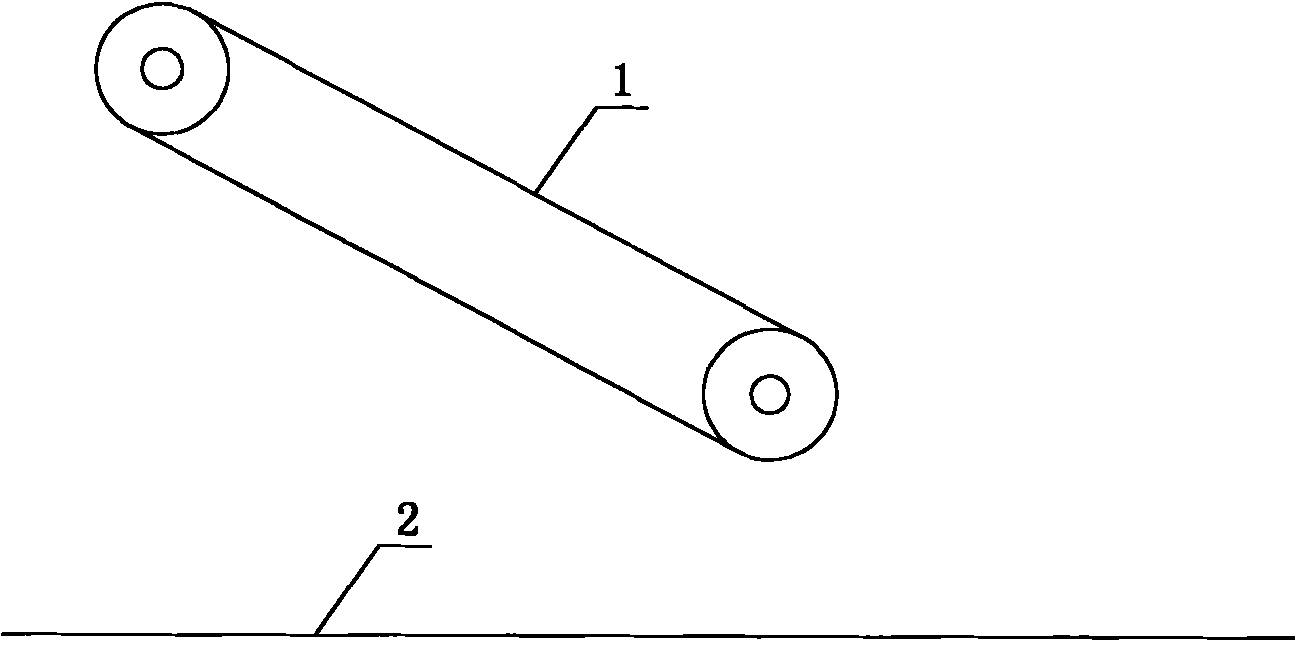

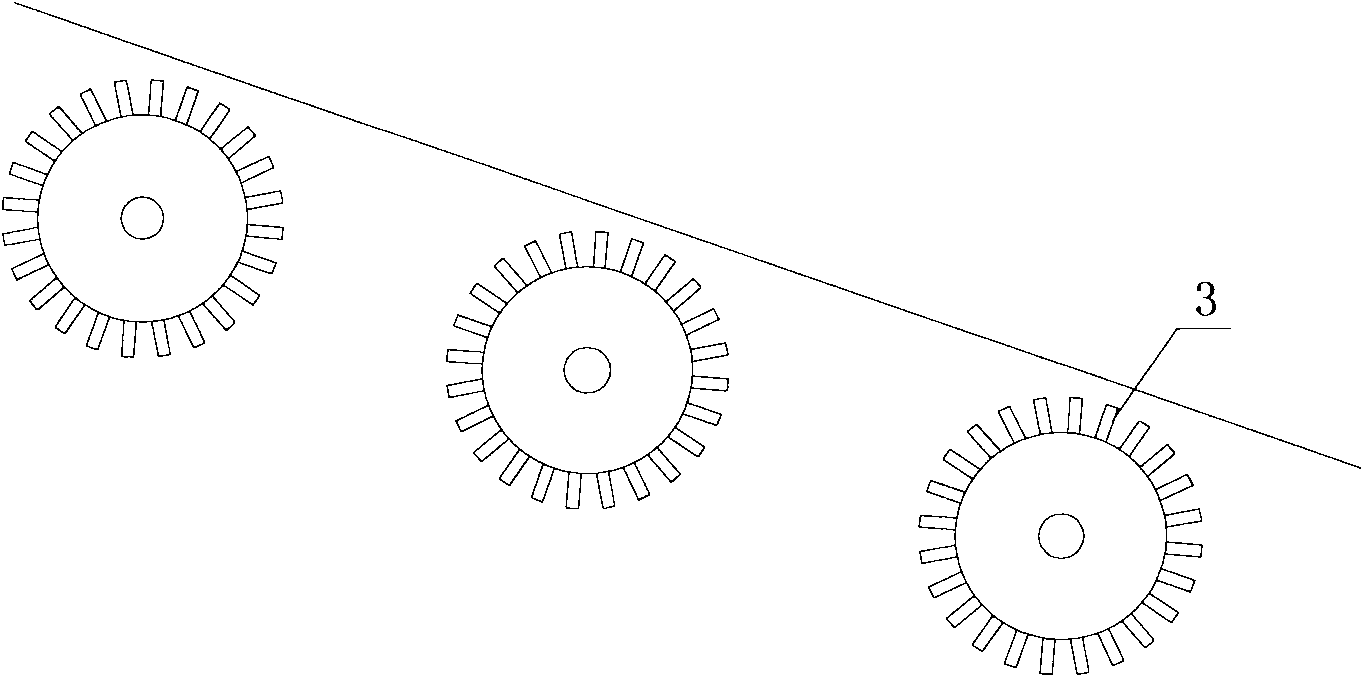

[0027]A method for producing cigarettes by using papermaking method reconstituted tobacco leaves into shreds, the method comprising the following steps: (1) packing the finished papermaking method reconstituted tobacco leaves in a box, the moisture content of the papermaking method reconstituted tobacco leaves is 10%-14%, cutting the package and opening the box, The loosening device breaks up the papermaking reconstituted tobacco and enters the bin; (2) After the papermaking reconstituted tobacco in the bin is lifted, use an electronic belt scale to control the flow of the papermaking reconstituted tobacco to ensure the uniformity of the flow; (3) from the electronic belt The paper-making reconstituted tobacco leaves are transported to the rewinding belt through the high-altitude vibrating trough equipped with meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com