Combined type mechanical crushing centrifugal pelletization device

A technology of mechanical crushing and centrifugal granulation, which is applied in the direction of recycling technology, etc., can solve the problems of low granulation percentage, large granulation particles, unfavorable heat exchange between particles and air, etc., and achieve an increase in granulation ratio, fine and uniform particles, Effect of increasing the throughput of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

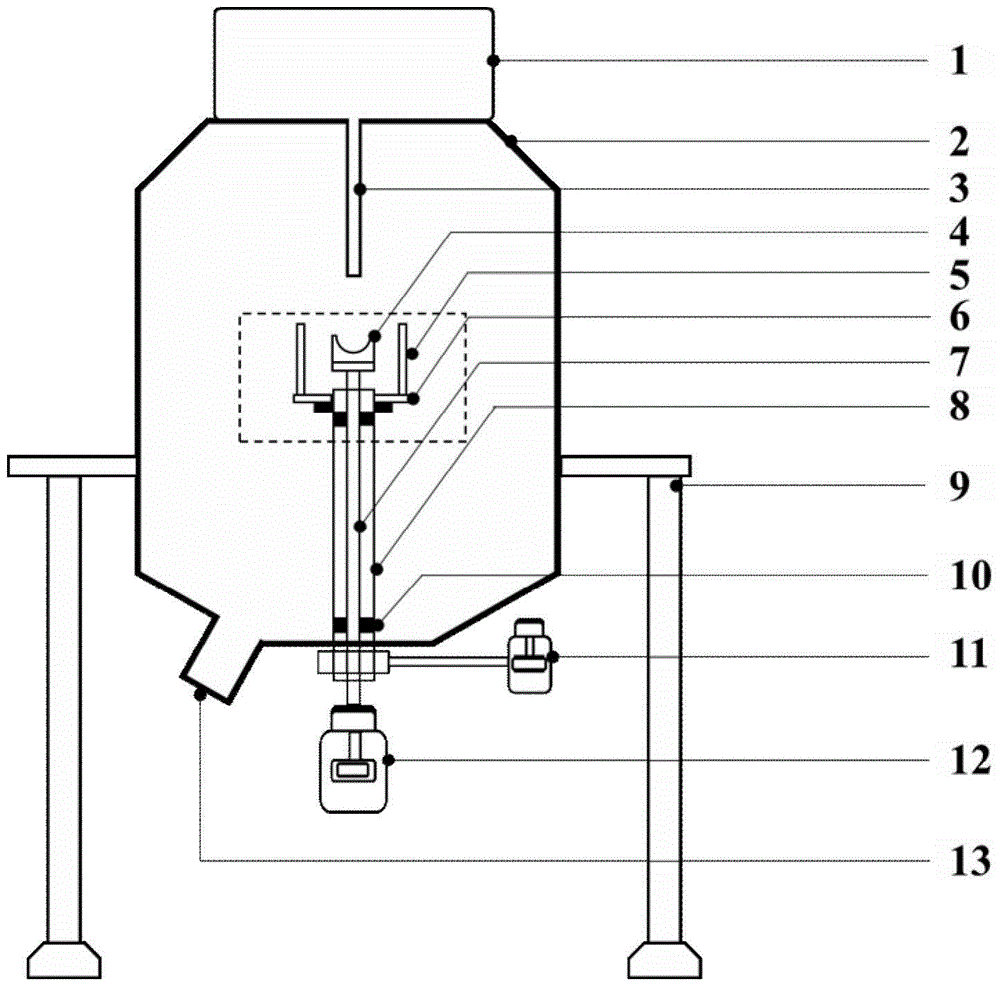

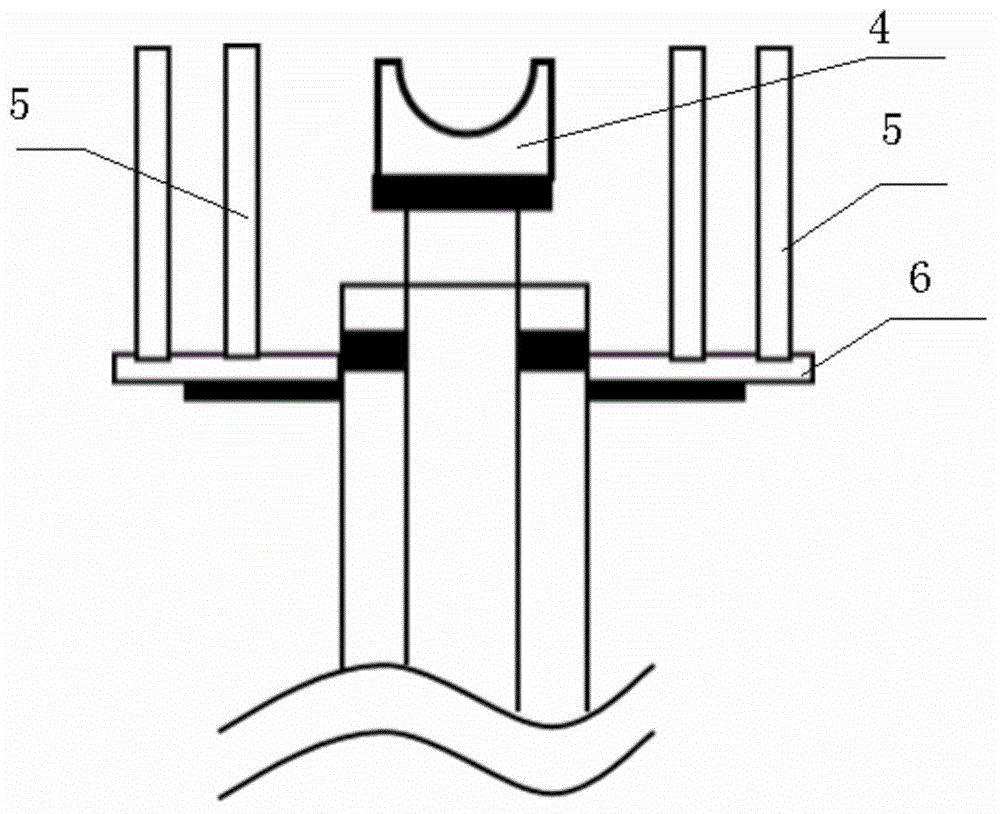

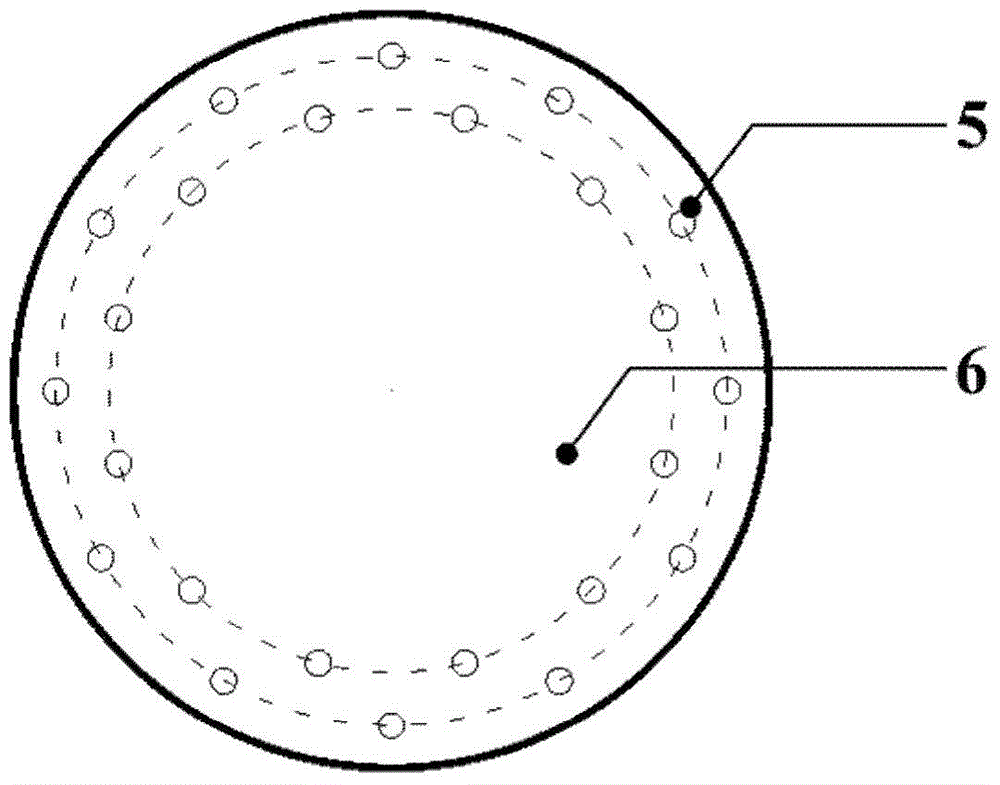

[0017] see Figure 1 to Figure 4 , a combined mechanical crushing and centrifugal granulation device, including a storage bin 1, a feed port 3 located at the lower part of the storage bin 1, a granulation bin 2, and a discharge port 13 located at the lower part of the granulation bin 2; the feed port 3 and the The storage bin 1 is connected, and the granulation bin 2 is fixed by the support column 9; a rotor 4 is arranged in the granulation bin 2, and the rotor 4 is located below the injection port 3, and the rotor 4 is fixedly sleeved On the inner rotating shaft 7, the inner rotating shaft 7 is passed through the hollow rotating shaft 8, and the inner rotating shaft 7 is driven by a motor one 12, the hollow rotating shaft 8 is supported by the inner rotating shaft 7 through a bearing 10, and the hollow rotating shaft 8 Driven by motor two 11; a rotating disc 6 is set below the rotor 4, and the rotating disc 6 is fixedly sleeved on the hollow shaft 8; a crushing blade is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com